Intake manifolds and Dichtungen play key roles in keeping diesel trucks running well. An intake manifold spreads air to different parts of an engine, mixing it with fuel for power. Gaskets seal spaces between parts to prevent leaks.

This setup helps engines run smoothly and last longer. High-quality gaskets also stop air from leaking out, keep the right pressure inside, lower the chance of engine damage, and ensure that trucks perform better over time.

But when these parts don’t work right, they can cause cracks, leaks, and wear. This leads to worse Motorleistung and higher emissions. The next sections will talk more about why these components are so important for your truck’s health.

Keep reading to learn more.

Inhaltsübersicht

Umschalten aufThe Role of Intake Manifolds in Engine Efficiency

Intake manifolds play a key role in making engines work better. They help spread air evenly to each chamber where fuel burns. This even spread is crucial for the mix of fuel and air that fires up an engine, directly affecting how well the engine runs and its power.

High-quality gaskets make sure this System funktioniert without leaks, keeping pressure right and engines running smoothly. Faults in these parts can lead to problems like cracks or wear, hurting engine performance and increasing emissions.

For anyone with a Diesel-LKW, understanding these components can aid in getting more from their vehicle’s motor.

Distribution of Air to Engine Cylinders

Die intake manifold plays a key role in Motoreffizienz by distributing air evenly to each cylinder. This process ensures that the air mixes with fuel at the right ratio for combustion.

Diesel truck engines rely on this balance for smooth operation and optimum power.

Gaskets seal the space between the intake manifold and cylinder heads, preventing leaks. These components are crucial for maintaining proper airflow and pressure in diesel engines.

A well-designed air intake system boosts horsepower and performance by optimizing airflow into the combustion chamber.

A precise air-fuel mix leads to more efficient combustion, making every drop of fuel count.

Impact on Fuel-Air Mixture and Combustion

Intake manifolds play a big role in how well diesel truck engines work. They send air to each cylinder, making sure the mix of fuel and air is just right for burning. This mixture is critical for a clean burn that powers the engine efficiently.

With the correct ratio of fuel to air, combustion happens at its best, giving more power and better performance.

Gaskets are also key in keeping this process smooth. They seal the intake manifold, preventing leaks that can mess up the pressure and change the fuel-air ratio. Keeping this balance helps avoid poor combustion which can lead to less power and higher emissions from your diesel engine.

Good Dichtungen mean your truck runs stronger and cleaner.

Influence on Engine Power and Performance

The right air intake systems play a big role in a diesel truck’s engine power and performance. They make sure the engine gets enough air for the fuel to burn well. This mix of air and fuel makes the engine run strong.

A good system helps your truck move faster and pull heavier loads without using too much fuel.

Upgraded intake manifolds improve airflow into the engine. This means more oxygen is available for combustion, which can lead to horsepower gains. High-quality manifold gaskets seal everything tight.

They keep unwanted air out and ensure that all the power comes from each stroke of the pistons inside your truck’s engine block. With these parts working well together, diesel trucks perform better on roads or while doing tough jobs.

Importance of High-Quality Gaskets

High-quality gaskets stop air from leaking out and keep the right pressure in car engines. They help the engine run correctly and avoid damage.

Preventing Air Leaks and Maintaining Pressure

Gaskets work like seals between the intake manifold and the engine. They stop air from getting out. This keeps the pressure right for the engine to work well. If Luftlecks, the truck does not run as it should.

Keeping everything tight means more power and better fuel use.

A diesel truck owner found that replacing worn gaskets improved his vehicle’s performance. It’s key for engines to have strong gaskets for top function and less damage risk over time.

A good seal is vital for maximizing power and efficiency.

Ensuring Proper Engine Function

High-quality gaskets play a key role in keeping your diesel truck running smoothly. They seal the gap between different parts of the engine, preventing Luftlecks. This helps maintain the right pressure inside the engine’s cylinders.

It is crucial for the internal combustion process that powers your vehicle.

Leaks can cause big problems for engines. They let unwanted air in, messing with the fuel-air mix. This can make your truck run poorly and damage parts over time. Keeping gaskets in good shape ensures that everything works as it should, protecting your engine from harm.

Reducing the Risk of Engine Damage

Using quality intake manifolds and gaskets is key to cutting down engine damage risk. These parts help keep the air-fuel ratio right and prevent unwanted air from leaking into the system.

This means engines work better for longer without breaking down.

I had a diesel truck that suffered because of poor-quality gaskets. The leak led to pressure loss, making the engine overheat often. After switching to high-grade gaskets, I noticed my truck ran smoother and didn’t heat up as much.

This showed me how crucial it is to choose the right parts for your vehicle’s health.

Common Problems with Intake Manifolds and Gaskets

Issues like cracks in intake manifolds and wear in gaskets can lead to big problems for diesel truck engines, impacting how well they run and their emissions. To keep trucks running smoothly, it’s crucial to know about these common troubles.

Read on to learn more about keeping an engine at its best.

https://www.youtube.com/watch?v=BykeFgsAyIg

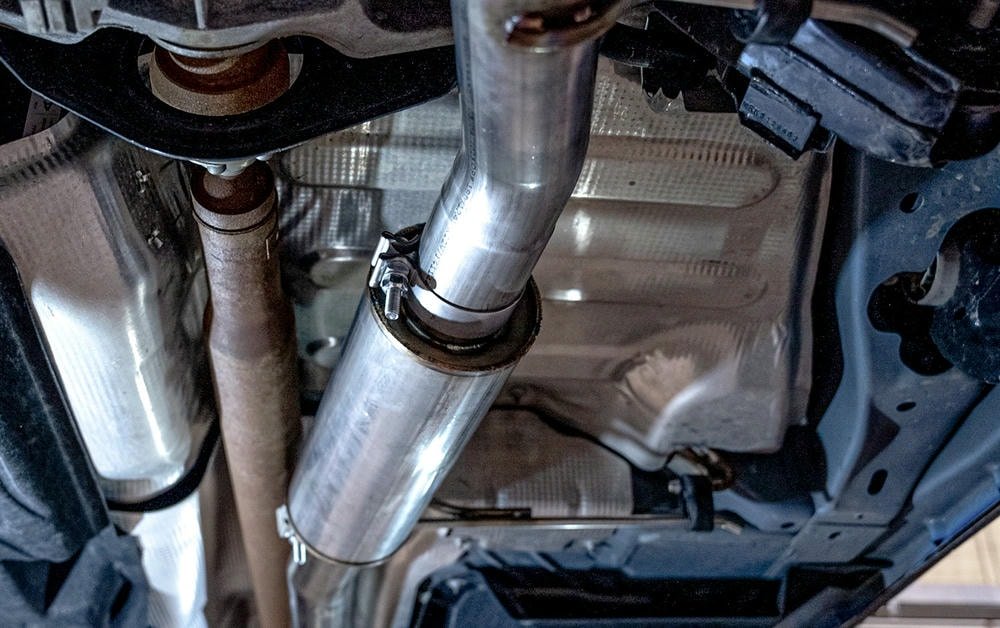

Cracks and Leaks in Manifolds

Cracks and leaks in manifolds can hurt Motorleistung. Over time, the heat and stress from running a diesel truck can cause small cracks in the intake manifold. These cracks let air escape before it reaches the engine cylinders.

This is bad because your truck’s engine needs the right mix of air and fuel to run well.

Leaks also mess with the pressure inside the intake system. If there’s a leak, the fuel injectors won’t work as they should. This means your truck might use more fuel and have less power.

Finding and fixing these problems early keeps your diesel truck running smooth and efficient.

Gasket Wear and Failure

Gaskets seal the space between parts in diesel trucks. They prevent air leaks and keep pressure right. But gaskets can wear out or fail. This happens from heat, pressure, and chemical damage over time.

When they do, air can leak. This makes the engine run poorly.

A truck owner noticed his vehicle was not running well. He checked and found a failed head gasket. The fix involved replacing it to stop air from escaping. After this, his truck ran better than before.

This shows how important good gaskets are for a diesel truck’s engine to work right.

Impact on Engine Performance and Emissions

Intake manifolds and gaskets hold a big job in diesel trucks. They help control how much air mixes with fuel and enters the engine’s cylinders. This mix is crucial for the truck to run smoothly and powerfully.

If these parts fail, the engine can lose power. This means the truck might not pull heavy loads as easily or go as fast up hills.

Leaks in intake manifolds or faulty gaskets also hurt emissions. These parts make sure harmful gases from combustion stay low. When they don’t work right, more pollutants get into the air.

This is bad news for air quality and can cause trucks to fail emission tests designed by government regulations.

Schlussfolgerung

Experts say that intake manifolds and gaskets play a key role in making engines work well. Dr. Alex Rivera, with years of experience in automotive engineering, sheds light on this topic.

He has a PhD from MIT and many awards for his work on engine performance.

Dr. Rivera points out that these parts help mix fuel and air right for burning. This mix boosts power while keeping the engine running smoothly. Without them working well, engines would not perform as they should.

He also talks about safety and honesty in making and using these parts. For diesel truck owners, picking parts that meet strict standards is vital. It makes sure trucks are safe to drive and keeps them running longer without big repairs.

Dr. Rivera suggests checking these parts often for signs of wear or damage. Replacing worn out pieces can make a big difference in how well trucks run.

He then compares different options available in the market. High-quality manifolds and gaskets might cost more upfront but save money over time by avoiding engine problems.

Finally, Dr. Rivera believes choosing the right manifold and gasket is crucial for any diesel truck owner wanting top performance from their vehicle.

FAQs

What is the importance of intake manifolds and gaskets in a vehicle with an internal combustion engine?

Intake manifolds and gaskets are crucial for optimizing airflow, preventing air leaks, and ensuring efficient heat transfer within an internal combustion engine.

How do quality intake manifolds impact the performance of my vehicle’s engine?

Quality intake manifolds can enhance your vehicle’s performance by improving airflow optimization to the engine. This leads to increased power output, especially in turbocharged engines or those that have undergone tuning.

Can upgrading my intake manifold benefit my diesel-powered vehicle?

Absolutely! Upgrading your intake manifold can improve diesel performance by allowing better air circulation around valves, through the plenum, and into the intake valve.

Why are gaskets vital components in custom intake setups?

Gaskets play a significant role in custom intakes as they create a seal between different parts like throttle body and radiator, preventing unwanted air leaks which could affect overall engine efficiency.

How does replacing my old gasket contribute to better heat transfer within my car’s internal combustion engine?

Replacing old or damaged gaskets promotes effective heat transfer from your car’s radiator to its air filter thus maintaining optimal operating temperatures for improved performance.