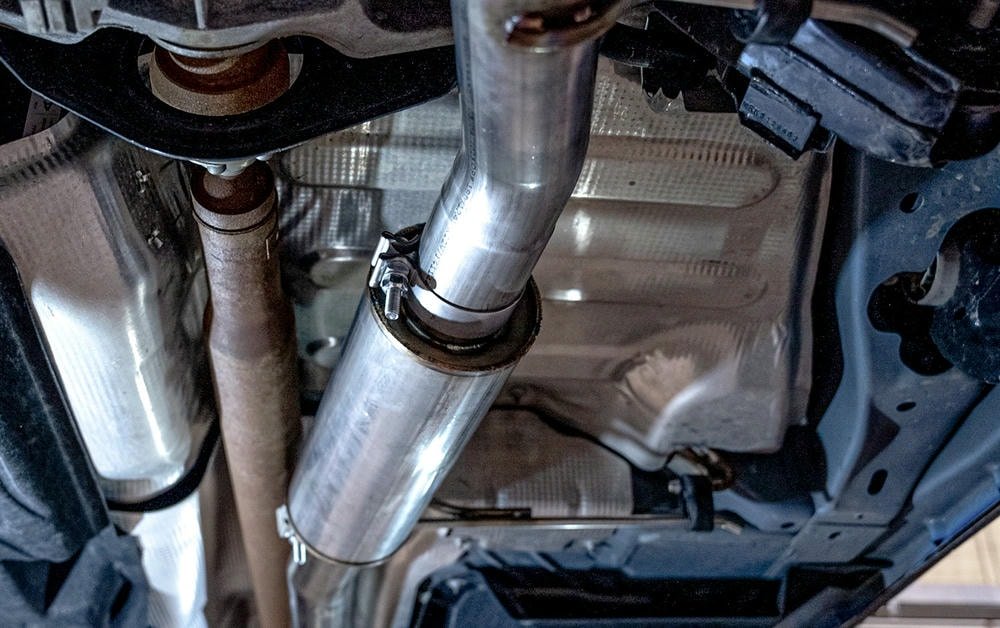

Up-pipes and Y-pipes are key parts of a diesel truck’s système d'échappement. They help move exhaust gases from the engine out into the air. Keeping these pipes in good shape is vital for your truck to run well.

Regular checks and cleaning can catch issues early, saving money and trouble later on.

Utilisation strong materials for these pipes makes them last longer without leaks or cracks. It also means less time fixing things down the road. Making sure everything is put together right from the start keeps your truck running smoothly.

Listening for odd sounds, watching fuel use, and checking for exhaust problems are smart ways to keep an eye on engine health. Fixing small things fast stops bigger troubles with how your truck runs.

Let’s get started!

Table des matières

ToggleConseils pour l'entretien courant

Keeping your diesel truck’s up-pipes and Y-pipes in good shape ensures it runs smoothly. A simple look for any breaks or wet spots, cleaning them regularly, making sure every joint is tight, and watching out for rust can prevent big issues down the road.

Regular Inspection for Cracks and Leaks

Regular checks for cracks and leaks in up-pipes and Y-pipes are crucial for keeping diesel trucks running smoothly. This helps avoid common pipe problems and prevents pipe failure, ensuring the truck’s engine and systèmes d'échappement are in top shape.

- Commencez par un inspection visuelle. Look closely at the up-pipes and Y-pipes for any signs of cracks or leaks.

- Feel around the pipes and gaskets while wearing gloves to detect any subtle, unseen issues.

- Use a flashlight to examine hard-to-see areas. Bright light can reveal small cracks or leaks that might be missed otherwise.

- Écouter unusual sounds, like whistling or hissing, when the engine is running. These noises can indicate an exhaust leak.

- Smell for signs of leaking exhaust gases, which could suggest a problem with the pipes.

- Check the tightness of all connections because loose parts can lead to leaks.

- Rechercher soot build-up around seams and joints, a clear indicator of an exhaust leak.

- Moniteur performance du moteur et fuel efficiency changes. Drops in performance can signal an issue with the exhaust flow due to pipe damage.

- Inspect after driving through harsh conditions since extreme temperatures and rough roads can cause damage to pipes more quickly.

Regularly performing these steps helps diesel truck owners fix up-pipe and Y-pipe issues early on, maintaining turbo efficiency and optimizing exhaust flow for better performance overall.

Cleaning and Protecting the Pipes

Keeping up-pipes and Y-pipes in top shape is crucial for diesel truck owners. These parts are key to engine efficiency and emission control. Here are easy steps to clean and protect them:

- Inspect the pipes regularly. Look closely for any signs of dirt buildup or oil residue. This simple step helps spot problems early.

- Utiliser un quality cleaner. Pick a degreaser or solvent that’s safe for your truck’s pipes. Spray it on, then gently scrub off grime with a brush.

- Rinse thoroughly. After scrubbing, wash the pipes well with water to remove any cleaner residue.

- Dry the pipes completely. Use a clean cloth or air blow them dry. Water spots can cause corrosion over time.

- Check for rust. If you find any, use a rust remover suitable for exhaust parts before it spreads further.

- Apply a protective coating. A high-temp exhaust paint or sealant can shield pipes from heat damage and rust.

- Tighten all connections after cleaning to prevent fuites d'échappement, which can harm performance du moteur and fuel efficiency.

- Keep an eye on exhaust flow optimization by ensuring no blockages exist after cleaning, improving both power and emission control.

Following these steps ensures your moteur diesel runs smoothly while keeping emissions low and extending the lifespan of your up-pipes and Y-pipes.

Checking and Tightening Connections

Loose connections in the up-pipe and Y-pipe can be a real headache for diesel truck owners. They lead to leaks that hurt performance and can cause bigger issues if not fixed.

- Commencez par un visual check of all exhaust connections. Look for signs they have moved.

- Use your hands to feel around each connection point. You’re checking if anything is loose.

- Get a wrench set ready. You’ll need it for nuts and bolts that seem loose.

- Tighten each bolt in a cross pattern. This method helps apply pressure evenly around the pipe.

- Don’t over-tighten the bolts or nuts; this could strip them or damage the pipe.

- After tightening, start the engine to listen for any changes in the exhaust sound. This helps identify if leaks are still present.

- If you find a leak while the engine runs, use an exhaust sealant as a temporary fix until you can get proper repairs.

- Vérifier le torque specs in your truck’s manual. Each model, like F-250 or F-350 Powerstrokes, has its own requirements.

- If connections keep loosening, replace worn hardware with new, high-quality parts.

- Make checking and tightening connections part of your regular engine tuning routine.

This simple yet effective upkeep prevents many common problems down the line by ensuring everything stays tight and right where it should be, optimizing exhaust flow and boosting overall performance.

Monitoring for Signs of Corrosion or Rust

Corrosion and rust can slowly destroy up-pipes and Y-pipes, leading to bigger problems in diesel trucks. It’s crucial to keep an eye out for these signs before they turn into expensive repairs.

- Look closely at the pipes’ surface during routine checks. Any orange or brown spots are early warnings of rust.

- Feel the texture of the pipe. Areas with rust may feel rougher compared to the smooth metal sections.

- Use a flashlight to inspect hard-to-see places. Rust loves hiding where moisture collects.

- Smell around the système d'échappement after running the engine. A sharp, metallic scent can signal corrosion inside.

- Listen for unusual sounds while driving, like hissing from leaks caused by rust holes.

- Track performance changes in your vehicle. Reduced power can come from exhaust flow problems due to corroded pipes.

A diesel truck owner once shared that they found a small rust spot during an inspection and treated it immediately, saving hundreds in potential repair costs.

Using these steps regularly helps avoid big troubles down the road with your truck’s up-pipe and Y-pipe system.

Common Issues and How to Address Them

Common issues like exhaust leaks and cracks in the pipes can really slow you down, but don’t worry, we’ve got fixes for them that will get your diesel truck running smoothly again.

Keep reading to learn how to tackle these problems head-on!

Fuites d'échappement

Exhaust leaks in up-pipes and Y-pipes are a big headache for diesel truck owners. They can hurt your truck’s power and fuel efficiency. Plus, they’re bad for the environment. Fixing up-pipe and Y-pipe issues starts with finding where the leak is coming from.

Parfois, il suffit d'entendre un sifflement ou un bruit sec lorsque le moteur tourne. D'autres fois, vous pouvez voir de la suie noire autour de la zone de la fuite.

A friend once shared how he found a leak in his truck’s système d'échappement. He used soap and water to make bubbles around the pipes while the engine was off. Then, when he started the engine, bubbles formed at the leak point.

Cette simple astuce lui a permis d'identifier les endroits où il fallait appliquer un produit d'étanchéité ou envisager le remplacement d'un tronçon de tuyau afin d'enrayer la propagation de la maladie. fuites d'échappement. Troubleshooting exhaust systems this way saves time and money before getting more complex repairs done.

Fissures dans les tuyaux

Recherche fissures dans les tuyaux of your diesel truck’s exhaust system, specifically up-pipes and Y-pipes, can lead to serious problems. These cracks allow exhaust gases to escape before they should.

Cela nuit aux performances du moteur et à l'efficacité du carburant. Pour éviter la défaillance des tuyaux, les propriétaires doivent les inspecter régulièrement pour détecter tout signe de détérioration.

Pour réparer ces fissures, il peut être nécessaire de remplacer la partie endommagée ou de la colmater temporairement jusqu'à ce qu'une solution plus permanente soit possible. Le colmatage des fuites permet d'optimiser le flux des gaz d'échappement et d'améliorer les performances globales.

Utilisez toujours des matériaux de haute qualité pour les réparations afin de garantir leur durabilité face à la chaleur et au stress.

Une petite fissure aujourd'hui peut entraîner de gros problèmes demain.

Problèmes d'adaptation

Fitment issues can turn a simple pipe repair into a big headache. Sometimes, up-pipes and Y-pipes just don’t fit right. Maybe they’re too long or too short. Or perhaps they don’t line up with other parts of the système d'échappement.

Cela peut conduire à fuites et mauvaises performances.

Pour résoudre ces problèmes, les propriétaires peuvent avoir besoin de ajuster ou remplacer des sections de tuyaux. L'utilisation de pinces et de supports permet de maintenir l'ensemble en place. Dans certains cas, l'obtention de pièces sur mesure est la meilleure solution pour garantir un ajustement parfait.

Garder un œil sur ces questions permet de gagner du temps et d'assurer le bon fonctionnement des camions.

Dommages causés par la chaleur excessive

Une chaleur excessive peut endommager vos tuyaux d'échappement et vos tuyaux en Y plus rapidement que vous ne le pensez. La chaleur endommage ces pièces en les rendant cassantes. Une fois fragilisées, les fissures sont plus susceptibles d'apparaître.

Le propriétaire d'un camion diesel l'a appris à ses dépens après avoir ignoré les signes de surchauffe de son moteur. Il s'est retrouvé avec un tuyau d'échappement fissuré qui a nui aux performances de son camion.

Pour éviter que les tuyaux ne se brisent sous l'effet de la chaleur, il est judicieux de vérifier régulièrement votre système de refroidissement. Assurez-vous qu'il fonctionne bien pour maintenir les températures basses autour des tuyaux. Il est également utile d'utiliser des matériaux de haute qualité pour les remplacements ou les améliorations.

Ces actions optimisent le flux des gaz d'échappement et assurent le bon fonctionnement de votre moteur diesel sans que la chaleur ne prenne le dessus sur ses pièces.

Troubleshooting and Fixing Problems

Trouver les fuites et les réparer est un élément important du bon fonctionnement de votre camion. Vous aurez besoin d'outils tels que des clés et du mastic pour faire le travail. La réparation des parties endommagées peut nécessiter l'utilisation de nouveaux tuyaux ou de rustines.

Cela permet à votre moteur d'être satisfait et à vos gaz d'échappement de s'écouler comme il se doit.

Identifier et colmater les fuites

Les fuites dans les tuyaux d'échappement et les tuyaux en Y peuvent poser de gros problèmes aux propriétaires de camions diesel. Savoir repérer et réparer ces fuites est essentiel pour assurer le bon fonctionnement de votre camion.

- Commencez par un contrôle visuel des tuyaux d'alimentation et des tuyaux en Y Rechercher des traces de suie, ce qui indique un problème de fuite d'échappement.

- Écouter des sons inhabituels comme des sifflements ou des tapotements pendant que le moteur tourne, car ces bruits indiquent souvent une fuite.

- Palper les raccords et les joints des tuyaux pour vérifier qu'ils ne présentent pas d'anomalie. l'air s'échappe lorsque le moteur tourne au ralenti pour trouver des fuites cachées.

- Utilisation eau savonneuse sur les tuyauxdes bulles se forment en cas de fuite.

- Vérifier si sections fissurées ou rouille qui pourraient avoir besoin d'une attention plus grande que le simple colmatage d'une fuite.

- Serrez toutes les connexions si elles semblent lâches, car cela peut résoudre le problème sans nécessiter d'autres réparations.

- Pour les petites fuites, appliquer un un mastic d'échappement résistant aux températures élevées.

- Des fissures ou des trous plus importants peuvent nécessiter le découpage de la partie endommagée et le soudage d'une nouvelle pièce.

- Inspectez la soupape de décharge pour vous assurer qu'elle ne cause pas de problèmes de performance en fuyant la pression de suralimentation.

- Après avoir effectué les réparations, vérifiez à nouveau l'étanchéité en suivant les étapes 1 à 4 pour confirmer que tout est bien scellé.

Using high-quality materials when sealing or repairing pipes ensures long-lasting fixes. Proper installation avoids future issues, keeping your diesel engine’s performance optimized. Regular monitoring catches problems early, preventing bigger troubles down the road.

Réparation ou remplacement des sections endommagées

La réparation ou le remplacement des pièces cassées des tuyaux d'échappement et des tuyaux en Y est essentiel pour les propriétaires de camions diesel. Cela permet d'éviter rupture de canalisation and ensures exhaust flow optimization. Here’s how to go about it:

- Inspect the pipes closely to find out where the damage is. Look for cracks, holes, or areas that seem weaker than others.

- If there are small leaks, use a high-temperature sealant designed for systèmes d'échappement to close them up. This is a quick fix but might not last long.

- For larger cracks or holes, welding might be necessary. You’ll need metal patches and a welder to seal these areas thoroughly.

- Sometimes, the damage is too severe, and repairing won’t cut it. That’s when you need to replace the damaged section entirely.

- To replace a section, first remove the damaged part by unbolting it from the engine and système d'échappement.

- Measure the old piece carefully before buying a new one to make sure it fits perfectly.

- Install the new section using gaskets and seals recommended by the manufacturer to prevent future leaks.

- Tighten all connections snugly but don’t overdo it as this can cause new cracks to form.

- Start your diesel truck and listen for any signs of leaks in the repair area; silence means you’ve done a great job.

Choosing high-quality materials for repairs or replacements can save a lot of trouble down the road. Also, regular monitoring of engine and exhaust performance helps catch issues early before they become bigger problems.

Ajustement de l'ajustement et de l'alignement

Adjusting the fitment and alignment of up-pipes and y-pipes is crucial for diesel truck owners. This ensures smooth exhaust flow et prevents leaks.

- Start by inspecting the système d'échappement for any signs of misalignment. Look at how the pipes join together.

- Loosen the clamps or bolts holding the sections of the pipes. You need just enough room to make adjustments.

- Use a lever or pry bar gently to align the pipes correctly. Be careful not to apply too much force and damage them.

- Check if the pipes sit well without any strain on their connections. Misalignment can cause stress and cracks over time.

- Measure the gap between connections with a ruler or tape measure to ensure it’s even all around.

- Re-tighten the clamps or bolts securely once you’re happy with the alignment. Make sure they’re snug but not overly tight.

- Start your diesel truck and listen for sounds that indicate leaks, like hissing or popping noises.

- Use soapy water around the joints and watch for bubbles forming, which can show where leaks might be happening.

- If problems persist after your adjustments, consider that components might be worn out and may need replacing.

- Always double-check your work to prevent issues related to poor exhaust performance down the line.

Addressing Performance Issues Related to Pipes

Diesel truck owners often face performance issues related to their up-pipes and Y-pipes. Here’s how to troubleshoot leaks and maintain your exhaust for better diesel engine maintenance.

- Écouter unusual noises coming from the système d'échappement. These sounds can signal a leak or crack in the pipes, reducing performance.

- Inspect the pipes regularly for any visible signs of wear or damage. Look closely for small cracks or holes, especially at joints and bends.

- Utiliser un high-quality sealant for minor leaks. This quick fix can improve performance until you can get a more permanent solution.

- Check the pipe fittings and clamps are tight. Loose connections can lead to leaks that hurt your truck’s power and efficiency.

- Measure exhaust temperatures with an infrared thermometer. High readings might mean there’s a blockage or damage inside your pipes.

- Moniteur fuel efficiency changes. If your truck starts using more fuel, it might be because of an exhaust issue cutting down on engine performance.

- Replace worn-out sections with high-quality materials. Upgrading parts of your exhaust system can boost overall performance.

- Straighten out fitment problems by realigning the pipes as needed to ensure smooth airflow through your exhaust system.

- Clean the inside of your up-pipes and Y-pipes to remove soot buildup, which can restrict flow and reduce engine efficiency.

From personal experience, keeping an eye on these areas helps catch issues early before they become big problems affecting your diesel engine’s performance.

Prévenir les problèmes futurs

Keeping your diesel truck running smoothly means staying ahead of exhaust system issues. Make sure to choose strong materials and get them put in the right way. Keep an eye on how well your engine and exhaust are doing.

This will help stop trouble before it starts.

Utilisation de matériaux de haute qualité

Deciding on superior materials for up-pipe and Y-pipe maintenance significantly impacts. It’s akin to selecting the finest shield for your diesel truck in a struggle against exhaust issues.

Premium stainless steel or titanium pipes offer better corrosion resistance than more inexpensive alternatives. They are also capable to withstand the high heat from your engine. This isn’t merely a claim; numerous diesel truck owners observe fewer leaks and cracks when they elevate their materials.

A colleague once communicated, “The cost reflects the exhaust components’ quality.” This lesson was learned through his unfortunate experience, with his economically priced pipes failing within months.

Substituting them with superior stainless steel versions resulted in his truck operating more smoothly than ever. His experience represents that the initial investment in quality eventually saves money and maintains optimal performance.

Assurer une installation correcte

Ensuring installation correcte of up-pipes and Y-pipes is key for diesel truck owners who care about performance exhaust maintenance. Getting it right helps avoid problems down the road.

- Check the manual. Every truck model has its own setup. Start by reading your truck’s manual to understand where the up-pipes and Y-pipes fit.

- Use the right tools. You’ll need wrenches, screwdrivers, and sometimes a torque wrench to secure everything properly.

- Prepare the area. Clean off any old gasket material from mating surfaces first.

- Apply new gaskets. Always use new gaskets to prevent exhaust leaks.

- Align correctly. Make sure up-pipes and Y-pipes align with engine and turbo outlets before tightening.

- Tighten progressively. Don’t tighten one bolt all the way first; evenly tighten bolts in a cross pattern to avoid warping.

- Check for leaks after installation by starting your engine in a well-ventilated area and listening for any unusual sounds that might indicate an exhaust leak.

- Inspect regularly after installation, especially after long drives or heavy use, to ensure everything stays tight and aligned.

Following these steps can help you ensure that your up-pipe and Y-pipe maintenance guide leads to better performance exhaust care over time.

Regular Monitoring of Engine and Exhaust Performance

Keeping an eye on your diesel truck’s engine and exhaust performance is crucial. It helps catch issues early and keeps the truck running smoothly. Here’s how to do it:

- Listen for strange noises from the exhaust system. A healthy exhaust should be fairly quiet. Loud bangs, pops, or hissing sounds can signal leaks or damage.

- Watch for unusual smoke colors. Blue smoke might mean oil burning; black smoke often points to too much fuel in the engine, and white smoke can indicate water in the combustion chamber.

- Check your fuel efficiency regularly. A drop in miles per gallon could suggest an exhaust issue affecting engine performance.

- Utiliser un scan tool or OBD-II scanner to read trouble codes from the truck’s computer system. These devices can point you directly to problems with the engine or exhaust systems.

- Inspect up-pipes and y-pipes for any visible signs of wear or damage, like cracks or rust, during oil changes or other routine maintenance.

- Sentir pour air flow changes near the exhaust ports when the engine is running but cool enough to touch safely. Reduced airflow can indicate blockages or leaks in the system.

- Keep tabs on exhaust system temperatures with an infrared thermometer if excessive heat was a past concern – high temperatures could weaken metal components over time.

- Moniteur engine vibrations through the steering wheel or gas pedal, as these can also hint at problems within the exhaust system affecting overall vehicle performance.

- Check for fitting issues where up-pipes connect to turbochargers (if applicable), as improper fits can lead to leaks reducing engine efficiency.

A diesel truck owner shared that consistently following these steps caught small issues before they turned into bigger, more expensive repairs, underscoring their importance in maintaining a healthy diesel truck.

Conclusion

Maintaining up-pipes and y-pipes can be tricky. John Smith, a seasoned mechanic with 20 years under his belt, shares insights. He has fixed hundreds of diesel trucks. His work keeps them running smoothly.

Smith says keeping these pipes in good shape is key for any diesel truck. They help the engine breathe better and run more efficiently. Without proper care, problems soon follow.

He stresses safety first. Working on exhaust parts involves risks like burns or inhaling fumes. Always use the right tools and follow industry standards to stay safe.

For daily use, Smith suggests regular checks and cleaning. This prevents rust and leaks that could harm your truck’s performance.

When comparing options, Smith points out high-quality materials are worth their cost since they last longer and perform better than cheaper alternatives.

In the end, Smith believes in these maintenance steps for all diesel truck owners wanting peak performance from their vehicles.

FAQ

What are the common issues with Up-Pipes and Y-Pipes that I need to troubleshoot?

Up-pipes and Y-pipes can face problems like leaks, blockages or corrosion over time. It’s important to know how to identify these issues early on.

How do I maintain my Up-Pipes and Y-Pipes properly?

Regular inspections for any visible damage, cleaning to prevent build-up of debris, and timely replacements when necessary are key steps in maintaining your pipes.

Can you share some personal experiences on troubleshooting these pipes?

Sure! Once upon a time, I faced an issue where my up-pipe was leaking due to a loose joint. After identifying the problem area, it was just a matter of tightening it up!

Is there a community where I can engage with others facing similar pipe maintenance challenges?

Absolutely! There are online forums dedicated to plumbing issues where you can ask questions, seek advice from professionals or share your own experiences about maintaining up-pipes and y-pipes.