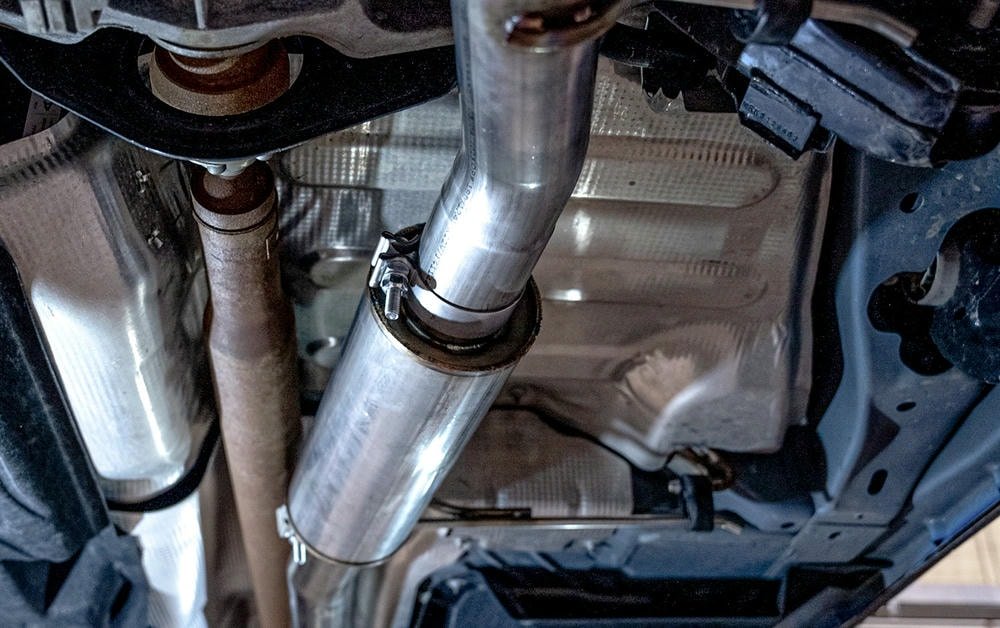

Setting up an exhaust manifold on a diesel truck requires precision. Mistakes such as incorrect gasket placement, over or under tightening of boltsou improper alignment of parts can result in leaks.

These issues also have the potential to affect your truck’s performance adversely. Ensure to utilize appropriate tools like torque wrenches for optimal bolt tightness and adhere to the guidelines provided by your truck’s manufacturer.

Before completion, verify the proper fitting of all components. Any discrepancies detected post-installation should be addressed promptly to maintain the optimal condition of your truck.

We will explore prevalent issues and their solutions.

Table des matières

ToggleCommon Installation Problems

Installing an exhaust manifold seems simple, but mistakes happen often. One common issue is placing the gasket wrong, which can lead to leaks and poor performance. Another problem is applying incorrect force to bolts, causing damage or misalignment.

Using the right tools and following instructions can help avoid these issues.

Improper Gasket Placement

Improper gasket placement can lead to leaks in the système d'échappement. A leak makes the engine lose power and efficiency. Gaskets must fit perfectly between the cylinder head and exhaust manifold.

They stop leaks from happening by sealing these two parts together tightly. If a gasket does not sit right, gases might escape.

“>Always ensure the gasket aligns properly with both the engine block and exhaust manifold before tightening bolts.”

To prevent improper placement, camion diesel owners should use correct tools like torque wrenches. They should also follow manufacturer instructions closely during installation. This ensures that every part is in its right place for optimal performance of manifolds, catalytic converters, and O2 sensors within an engine’s exhaust flow path.

Incorrect Torque on Bolts

Applying the wrong torque to bolts is a big mistake during exhaust manifold installation on diesel trucks. This error can lead to leaks, which harm engine performance and fuel economy.

Bolts must have just the right tightness. Too loose, and gases escape before reaching the tail pipes. Too tight, and bolts might break or damage the cylinder heads.

To avoid this problem, use a torque wrench for precision. Follow manufacturer’s settings closely. Each engine has its own needs for bolt tightness. Check these settings against your truck’s manual or reliable auto repair guides online.

Recheck the torque after a few miles of driving since bolts can settle or shift slightly under normal conditions.

Misalignment of the Manifold

Misalignment of the manifold affects diesel truck engines badly. It stops the système d'échappement from working right, causing power loss and higher fuel use. To fix this, one must check alignment with tools like a straightedge or feeler gauge.

These tools help spot gaps or mismatches between the manifold and engine head.

Fixing misalignment starts by loosening bolts slightly, then realigning everything carefully. After setting it straight, retighten bolts in a cross pattern to spread pressure evenly.

This method helps avoid warping and ensures a good seal with gaskets, keeping harmful gases out of the cabin and improving engine performance.

Inadequate Sealing Leading to Leaks

Leaks in the système d'échappement often come from poor sealing at the manifold. This issue puts the engine at risk. It can lead to lower performance and harm parts like oxygen sensors. A diesel truck owner found out that their vehicle was not running well.

They checked and saw leaks where the exhaust manifold meets the head gaskets.

To fix this, they made sure all surfaces were clean before putting on a new gasket. They also used correct torque settings with their tools to avoid over-tightening bolts, which can crush or misshape the seal.

This hands-on approach stopped leaks and helped their truck run better.

A tight seal is key for an système d'échappement to work right.

How to Avoid Installation Issues

To avoid problems when setting up your système d'échappement, follow the maker’s guide closely. Use the right tools and make sure bolts are tight just enough. Place gaskets correctly and check everything lines up before tightening anything down.

This helps prevent leaks and other troubles so your vehicle runs smoothly. Keep reading for more tips on how to do this right.

Following Manufacturer’s Instructions

Manufacturers provide a manual for a reason. It guides diesel truck owners through the correct steps of exhaust manifold installation. This means placing gaskets right, setting bolts with proper torque, and aligning manifolds accurately to ensure no leaks or performance issues arise.

Manuals often include specific details about the tools needed, like torque wrenches and gasket sealers, making sure every step is clear and easy to follow.

Ignoring this guidance can lead to costly mistakes such as cracked manifolds or engine damage from leaks. Each model of diesel truck might have unique requirements for installing an exhaust manifold that only the manufacturer’s instructions will cover accurately.

Following these instructions helps prevent common errors in sealing, bolt tightening, and alignment which ensures optimal exhaust flow optimization and vehicle performance without unwanted visits to the garage for repairs.

Using Proper Tools and Torque Settings

Using the right tools and adjusting bolts to the correct tightness can make or break an exhaust manifold installation. A torque wrench is crucial for this job. This tool allows diesel truck owners to apply a specific amount of force on a bolt, making sure it’s neither too loose nor too tight.

Too much force can strip threads or break bolts, while not enough leaves gaps for leaks.

One person found out the hard way that guessing the needed tightness wasn’t enough. After fitting a new manifold without using a torque wrench, they faced annoying leaks. It was only after they used the prescribed settings from their vehicle’s service manual with a proper torque wrench that they solved the issue.

This teaches us to always use accurate tools and follow guidelines closely.

The right tool does half the work.

Ensuring Correct Gasket Placement

To make sure the gasket fits right, check its shape against the exhaust manifold and engine block. Ensure it lines up perfectly with every hole. This step prevents leaks and maintains a tight seal.

L'utilisation d'un torque wrench helps apply just enough force to hold everything in place without damaging parts.

Diesel truck owners should replace old gaskets with new ones to avoid problems like leaks or corrosion. It’s important not to skip this step during installation. A correctly placed gasket improves performance and stops harmful gases from escaping into areas they shouldn’t be.

Checking Alignment Before Securing Bolts

Checking the alignment of an exhaust manifold is critical to ensure a proper fit on diesel trucks. One must place the manifold against the cylinder head and visually check that all ports line up correctly.

This step is important to avoid exhaust leaks, which can lead to reduced performance or damage. Using tools like straight edges helps in confirming that the surfaces are flush, ensuring a snug fit before tightening any bolts.

After confirming alignment, it’s time to secure the bolts. One must follow a specific pattern and use a torque wrench set to the manufacturer’s recommended settings. This ensures even pressure across the manifold, preventing warping or cracks due to uneven tightness.

Properly torqued bolts are key for maintaining an effective seal between the manifold and cylinder head, crucial for optimal engine performance and longevity.

Troubleshooting Installation Problems

Fixing problems after installing an exhaust manifold needs careful steps. First, diesel truck owners must find and fix any parts that do not line up right. They must also spot leaks early and know how to tighten bolts again without making mistakes.

Tools like torque wrenches help set the right tightness on bolts. To stop leaks, checking gasket placement is key. If leaks exist, applying sealant correctly or replacing faulty gaskets can solve the issue.

This ensures a strong connection between the manifold and the engine block, stopping harmful gases from escaping.

Identifying and Correcting Misalignment

Correcting misalignment in an exhaust manifold begins with identifying the issue. Diesel truck owners should check if the manifold does not sit flush against the engine block. This gap can cause leaks, which hurt performance and fuel efficiency.

To spot this problem, one might use a straight edge tool along the surface where the manifold meets the engine. Misaligned parts will show gaps.

To fix misalignment, loosen the bolts holding the manifold slightly but do not remove them entirely. Use a mallet to gently tap on areas of high resistance to shift into place correctly.

Once aligned, retighten each bolt in a cross pattern to ensure even pressure across all points of contact between exhaust pipes and gasket surfaces; this method prevents future leaks and maintains optimal engine function without inducing strain on any single point.

Addressing Leaks After Installation

Finding leaks after fitting a new exhaust manifold can be stressful. The first step is to check the gasket’s placement and ensure it fits perfectly without any gaps or misalignment.

A properly seated gasket prevents gases from escaping, which could lead to fire risks in flammable areas like a gas station. Use a torque wrench to make sure all bolts are tightened correctly, following the manufacturer’s guidelines.

If leaks persist, inspect for cracks in the manifold itself or corrosion that might have been missed during installation. Sometimes, replacing damaged parts is the only way to stop leaks.

For ongoing maintenance, apply corrosion protection products to shield the système d'échappement from rust and decay. Diesel truck owners should also regularly listen for unusual noises or signs of burning, as these could indicate an unresolved leak that needs immediate attention.

Retightening Bolts as Needed

After the exhaust manifold is in place, bolts might loosen over time. This can happen because of vibrations and heat from the engine. To prevent leaks or damage, it’s crucial to check these bolts regularly.

Utiliser un torque wrench for this task. It ensures that each bolt has just the right amount of tightness.

A diesel truck owner shared his experience on an online forum. He didn’t check his manifold bolts after installation. A few weeks later, he noticed a strange noise coming from the engine area.

After inspecting, he found that several bolts had loosened significantly, leading to an exhaust leak. Once he tightened them with the correct torque setting, using his torque wrench, the problem was solved.

This shows how important regular checks are to maintain your vehicle’s performance and safety.

Conclusion

Issues with exhaust manifold installation can cause big problems for diesel truck owners. John Smith, an expert in vehicle engineering, talks about these issues. He has worked in this field for over 20 years.

Smith studied at Tech University and won awards for his work on systèmes d'échappement.

Smith says that installing the manifold right is key to a truck’s performance. Problems like wrong gasket placement can hurt the engine. Proper tools and following instructions prevent these errors.

He stresses safety and honesty in this process. Companies must follow rules and be clear about their products.

For everyday use, checking alignment and sealing helps avoid leaks and keeps trucks running well.

Smith sees pros and cons in manifold installation. Done right, it boosts engine power but wrong steps can lead to damage.

His final word? Paying attention to detail during installation pays off for diesel truck owners.

FAQ

What are some common problems with exhaust manifold installation?

Common issues include improper fitting of the manifold gaskets, difficulty in turbocharger integration, and errors during engine tuning. These can impact performance exhaust fitting and custom exhaust setups.

How can I troubleshoot these manifold installation issues?

To troubleshoot, you should first inspect your header for signs of corrosion as this is a common issue with exhaust manifolds. You may also need to check the OBD-II system in cars or electric vehicles for error codes related to the SOHC or DOHC systems.

Are there specific mistakes to watch out for when setting up an exhaust system?

Yes, one mistake could be incorrect setup around the throttle body which might lead to power stroke inefficiency. Another mistake could be improper handling of the Exhaust Gas Recirculation Valve (EGR valve) during installation.

Can these issues cause smoke from my vehicle’s tailpipe?

Indeed! Issues like corroded manifolds or improperly installed gaskets can cause leaks that result in visible smoke from your car’s tailpipe.

How can I prevent these manifold installation errors?

Preventing such errors involves careful attention during each step – from ensuring correct alignment of parts like headers and gaskets, monitoring boost levels during turbocharger integration to using proper tools and techniques throughout.