Diesel truck owners know the importance of quality parts. Pipes and boot kits for diesel engines come in materials like aluminum, stainless steel, silicone, and rubber. Each material suits different needs.

For example, stainless steel pipes resist rust and wear well. Silicone boots work best with high heat. Choosing right depends on what the engine does. High performance means needing strong materials that handle heat and pressure well.

Matching pipes and boots to your vehicle helps it run better. The truck’s manual can show the best fit. Good parts prevent leaks and damage This saves money later.

Learn more about choosing the right parts next.

Table des matières

ToggleTypes of Pipes Used in Diesel Engines

Diesel engines use different types of tubes to run well. Some are made from metal, while others come from rubber or special plastics. This variety helps the travail du moteur better in various conditions.

Aluminum Pipes

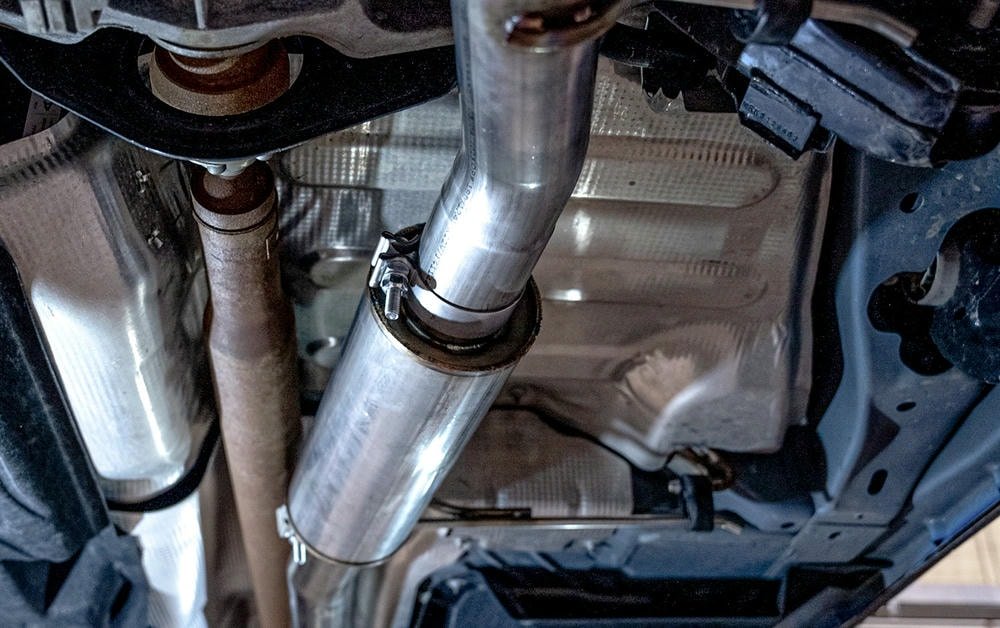

Aluminum pipes are a top choice for diesel engine upgrades, especially in turbocharged engines. They are light and help the engine work better. Their strength lets them handle high pressures and temperatures without getting damaged.

This makes them perfect for both système d'échappement parts and intercooler piping.

Owners often pick aluminum pipes for custom piping setups because they cut down on weight. This can lead to better performance and fuel efficiency. Also, these pipes resist rust, which is great for long-term use.

People who have used aluminum pipes in their trucks report noticeable improvements. They say their vehicles run smoother and cooler, making driving more enjoyable.

Stainless Steel Pipes

Stainless steel pipes are a premier choice for camion diesel proprietors aiming to improve their engines. These pipes are notable for their rust and heat resistance – a quality that renders them ideal for high-performance alterations where sturdiness is vital.

Many individuals who fine-tune diesel engines favor stainless steel due to its robustness and ability to endure under intense conditions.

An individual with direct involvement might express, “I selected stainless steel pipes for my diesel engine because I required something robust that could withstand the demanding conditions of tuning and performance upgrades.” This demonstrates the importance of selecting the appropriate materials while improving an engine for superior performance.

Stainless steel endures longer and also ensures there aren’t any leaks or weaknesses in the vehicle’s plumbing system, maintaining its smooth and efficient performance.

Silicone Pipes

Silicone pipes are a top choice for diesel engine owners seeking reliable and durable tubing. Unlike rubber or metal alternatives, these pipes can manage extreme temperatures from hot to cold without losing shape or strength.

They prove useful in both heavy-duty trucks and high-performance engines due to their superior resistance to heat, oil, and chemicals. This attribute makes silicone pipes ideal for those intending to challenge their diesel engines with performance enhancements.

From direct experience, many diesel truck owners favor silicone over others due to its flexibility. They fit snugly in confined spaces under the hood, simplifying installation. Furthermore, they are available in an array of sizes and shapes to comply with different engine layouts.

For anyone contemplating enhancements such as engine optimization or tuning, opting for silicone provides a leak-proof seal that withstands pressure without cracking or deteriorating over time.

Rubber Pipes

Rubber pipes are common in diesel engines. They work well for moving fluids like water, oil, and fuel. These pipes handle high temperatures and pressure without breaking. Rubber is flexible.

It bends around corners in the engine space easily. This makes rubber pipes good for complex layouts.

These pipes also seal tight against leaks. When put with silicone rubber sealants, they prevent liquids from escaping. This is important for keeping engines dry and safe. Diesel truck owners often choose rubber pipes for their durability and easy fit in tight spaces.

Types of Boots Used in Diesel Engines

In diesel engines, different boots like silicone, rubber, and fluorocarbon-lined play key roles. These boots handle high pressure and temperature changes well. They make sure connections stay tight and keep the engine running smoothly.

Each type has its uses based on how much heat or pressure it can take. Learning about these will help you pick the best fit for your truck. Explore more to find which suits your needs best.

Silicone Boots

Silicone boots are great for diesel trucks because they handle heat very well. They keep engines safe by making sure air and water stay out. People like them because they last a long time.

These boots can stand up to oil, mildew, and extreme temperatures without breaking or getting weak.

A truck owner shared that after switching to silicone boots, their engine worked better in both hot and cold weather. This shows how well these boots protect against leaks and damage.

They fit snugly on pipes, keeping everything tight and secure. For anyone wanting a tough solution, silicone boots are the way to go.

Rubber Boots

Rubber boots are key for diesel engines, especially when dealing with flashings, watertight sealset air-tight connections. These boots keep water out of places it shouldn’t be, like where your engine meets its pipes.

Think about how rubber boots work on roofs or in showers. They stop leaks by forming tight seals.

In diesel trucks, these rubber parts play a big role. They handle extreme temperatures and vibrations without cracking or breaking down. This makes them great for plumbing systems in vehicles.

Plus, they’re affordable. Installing new rubber boots can prevent costly damage to your truck’s engine.

Fluorocarbon-lined Boots

Fluorocarbon-lined boots stand out among engine boot kits, especially for diesel tuning. These boots handle high temperatures very well. They resist wear and chemicals too. Diesel truck owners often choose them for their durability.

These boots make sure the connections stay safe under tough conditions.

People with experience say these boots last longer than others. This can save money in the long run. For performance mods on diesel engines, choosing fluorocarbon-lined boots is a smart move.

They help the engine work better by keeping everything tightly sealed and protected from heat and chemicals.

Choosing the Right Pipes & Boot Kits

Picking the best pipes and boot kits means looking at how they perform and if they fit your truck. Check how tough they are and if they can handle high heat to make sure you choose ones that last long.

Matching Materials to Performance Needs

Choosing the right materials for pipes and boot kits in diesel engines involves understanding what your truck needs. Different tasks require different types of pipes and boots. For high-temperature conditions, silicone boots are a good choice because they can handle the heat without breaking down.

On the other hand, aluminum and stainless steel pipes are perfect for those who need strong airflow without rusting.

Evaluating performance needs means looking at how you use your diesel truck. If you’re always carrying heavy loads or driving in rough conditions, durability becomes key. Fluorocarbon-lined boots might be the best pick here because they resist wear from oils and chemicals better than others.

A friend once said, “Match your gear to your journey.” This advice rings true for selecting pipes and boot kits too. Know what challenges your engine faces regularly to make smart choices that will last.

Evaluating Durability and Resistance to Heat

Durability and heat resistance are key when choosing pipe and boot kits for diesel engines. Pipes and boots must handle high temperatures without breaking down. For pipes, materials like stainless steel stand up well to heat and wear.

Silicone boots resist high temps too. Owners have seen these parts work hard without failing, even in tough conditions.

Heat affects different materials in various ways. Stainless steel pipes can take more heat than aluminum ones before they warp or weaken. Silicone boots keep their shape better than rubber when things get hot.

Knowing how each material reacts helps owners pick the right parts for their trucks, ensuring long-lasting performance and safety on the road.

Compatibility with Your Vehicle

Checking if pipes and boot kits fit your diesel truck is key. Every truck model has its own needs. A kit perfect for one might not work for another. Owners should look at their vehicle’s manual first.

It lists the right size and type of parts.

Some trucks need special pipes or boots because of how they’re built or what they do. For example, heavy-duty trucks doing a lot of towing might need stronger materials that can handle more heat and pressure.

This means picking stainless steel pipes over aluminum ones sometimes.

Owners also learn from using different kits on their trucks. They find out what lasts longer or performs better under tough conditions. Sharing these experiences helps others choose the right products for their vehicles too.

Making sure the pipe and boot kit match with your vehicle makes it run better and last longer without needing lots of repairs.

Conclusion

John Masters, an expert in diesel engine technology, shares his insights. He has worked in this field for over 20 years. John holds a degree in mechanical engineering and has many articles on engine performance.

John talks about pipes and boot kits. He says they are key for a diesel engine’s best work. Pipes and boots need to match the engine’s needs. They must handle high heat and resist wear.

He points out important things like safety and honesty in making these parts. Products should meet strict rules and show all details clearly.

John suggests using silicone or stainless steel for high heat areas. Rubber works well for less intense places. Choosing right helps your vehicle run better.

He compares types of pipes and boots. Each kind helps the engine in different ways, but not every type fits every situation.

Finally, John believes good quality pipes and boot kits make a big difference in diesel engines’ performance. Owners should think about their vehicle’s needs before choosing.

FAQ

What are the best types of pipes and boot kits?

The best type of pipes and boot kits depend on their intended use. For diesel engine applications, specific pipe and boot kits are available. While for home installations like sinks, bathrooms or toilets, different types can be used.

How does roofing material affect the choice of pipe and boot kit?

Roofing materials such as shingles, concrete or metal roofing significantly influence your choice of pipe and boot kit. You need to ensure compatibility between these elements for effective waterproofing.

Can I use the same type of pipe across all areas in my house?

No, different areas require specific types of pipes based on their function. For instance, insulation walls might need a different kind compared to those used in bathrooms or kitchens.

How do I compare various pipe and boot kits?

When comparing various pipe and boot kits consider factors such as durability, compatibility with other materials like sheet metal or concrete, ease-of-installation and cost-effectiveness.

Is sawing necessary while installing pipes & boots?

Yes! Sawing is often required during installation especially when dealing with rigid materials such as sheet metal roofs or concrete bases.