Improving cold air intake performance is a key method for diesel truck owners to increase power and fuel efficiency. This process involves upgrading parts like high-flow air filters, intake tubinget heat shields.

These upgrades help trucks breathe better, which means they can run stronger and more efficiently. Regular maintenance also plays a crucial role in keeping the cold air intake system free from clogs that could harm engine function.

Simple changes and more advanced tweaks can make a big difference in how well a camion diesel performs. Let’s explore how to do this right.

Table des matières

ToggleSimple Upgrades and Modifications

Making your cold air intake work better can start with a few simple changes. Adding high-performance air cleaners and improving the pipes that bring in the air can greatly boost how well your engine breathes.

High-Flow Air Filters

High-flow air filters allow your diesel truck’s engine to breathe easier. This means the engine gets more air with every intake cycle. More air leads to a better fuel and air mix. This can boost power and efficiency in your motor.

Brands like K&N or Fram make these high-performance filters. They design them to increase airflow while keeping dirt out of your engine.

A diesel truck owner tried one and noticed better throttle response and fuel use. They shared, “After installing a high-flow filter, my truck felt more responsive.” These filters are not just for show; they improve how your vehicle runs.

Better airflow equals a stronger, more efficient engine.

Upgraded Intake Tubing

Upgrading intake tubing can make a big difference in diesel trucks. It helps the engine breathe easier. This means more air gets to the engine, and it works better. Good tubing also keeps the air cooler.

Cooler air is denser. Denser air helps the engine produce more power.

Choosing the right material for upgraded tubes is key. Aluminum or silicone tubes are popular choices. They handle high temperatures well and keep airflow smooth. Smooth airflow is important for efficiency and power.

Experts often recommend upgrading to wider tubes too when aiming for performance boosts in diesel engines, turbocharging systems greatly benefit from this as they rely on efficient airflow to operate at their best levels, thus improving fuel efficiency while reducing exhaust emissions which aids in keeping engines healthier over time.

Heat Shield Enhancements

Improving airflow and reducing the engine’s intake temperature can make a diesel truck run better. One way to do this is by improving the heat shield around the cold air intake system.

Heat shields work by blocking hot air from the engine and exhaust, allowing only cool air to reach the intake manifold. This helps increase turbocharger efficiency and fuel efficiency.

People have found that adding or upgrading heat shields can make their trucks perform better. They use materials that reflect heat away from the cold air intake area. Some even customize their setups for better protection against heat.

Tests show that cooler intake temperatures can lead to more power and improved fuel consumption because engines breathe easier with cooler air.

Throttle Body Spacers

Throttle body spacers add a bit of space between the throttle body and intake manifold. For diesel truck owners, this means meilleure circulation de l'air to the engine. The spacer makes the air go into the engine in a swirl pattern.

This helps in mixing fuel and air better. Trucks get more power and might use less fuel as well.

People who have tried them on their trucks notice small gains in horsepower and fuel efficiency. They also say that installing these spacers is easy. Diesel engines work harder than car engines, so any boost helps.

Utilisation throttle body spacers is a cost-effective way to improve performance without big changes.

Advanced Performance Improvements

For those looking to push their diesel trucks further, advanced performance enhancements offer a new level of optimization. Tuning the engine’s computer and making sure it works well with other upgrades can lead to better power and efficiency.

Keeping things clean and in good shape is just as critical for top performance. These steps take the truck’s abilities up a notch, inviting owners to explore the full potential of their vehicles.

Custom Tuning and ECU Adjustments

Custom tuning and ECU (Engine Control Unit) adjustments are key for improving diesel truck performance. These changes allow the engine to respond better, using air and fuel in the most efficient way.

Experts use tools like dynos to measure outcomes. This helps them find the perfect settings for each truck’s ECU. A well-tuned ECU can lead to noticeable gains in horsepower, torque, and even fuel efficiency.

A diesel truck owner shared their experience: after custom tuning their vehicle, they saw a significant rise in power and smoother driving on highways. This shows how adjusting a few settings can have big effects on performance.

Getting my truck custom tuned was like unlocking a new level of energy it had hidden all along.

Integration with Other Performance Upgrades

Integrating a cold air intake system with other performance upgrades can dramatically improve a diesel truck’s power, efficiency, and engine response. Owners often see substantial benefits from such combinations.

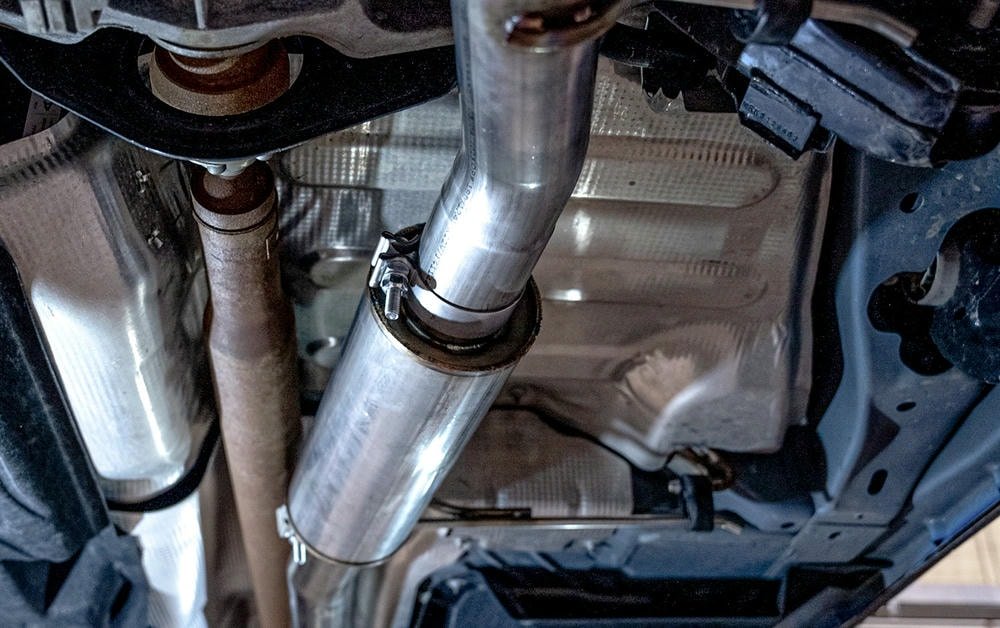

- Match the cold air intake with a high-flow exhaust system. This allows air to flow more freely through the entire engine, improving power and fuel efficiency. Together, they reduce back pressure and enhance exhaust expulsion, making room for more air and fuel in the combustion chamber.

- Install a larger or upgraded mass airflow (MAF) sensor. A bigger MAF sensor can read increased air flow rates more accurately, optimizing fuel injection for better performance.

- Connect the cold air intake to a turbocharger or supercharger for even greater gains in horsepower and torque. These forced induction systems pressurize the air entering the engine, allowing it to consume more fuel and produce more power.

- Utiliser un performance-grade fuel injector alongside your cold air intake. More powerful injectors supply higher amounts of fuel into the combustion chamber, meeting the increased oxygen supply from your improved air intake system.

- Regularly clean and maintain both the cold air intake and associated upgrades like filters on turbochargers or superchargers to ensure optimal performance levels are maintained.

- Conduct custom ECU tuning after installing your cold air intake with other modifications. This fine-tunes your diesel truck’s computer to recognize and effectively use these new components together for maximum output.

- Include an aftermarket throttle body paired with your cold air intake for better throttle response and faster acceleration due to increased airflow into the engine.

- For trucks already equipped with an aftermarket exhaust or considering one, combining this upgrade with your cold air intake further harmonizes airflow in and out of the engine compartment, particularly enhancing fuel economy at cruising speeds.

Each of these steps makes sure that diesel truck owners benefit from each component’s full potential when integrated correctly with a cold-air intake system, leading to significant improvements in overall vehicle performance.

Regular Maintenance and Cleaning

Keeping the cold air intake system of a diesel truck in top shape is crucial for performance and fuel efficiency. Regular maintenance and cleaning prevent buildup that can restrict airflow and degrade engine function.

- Vérifier le air filter monthly. Dust and debris collect here first. A clogged filter limits the amount of air reaching the engine, reducing power and efficiency.

- Clean or replace the air filter every 15,000 miles, depending on usage. In dusty environments, this may need to happen more frequently.

- Inspect all clamps and connections during filter checks. Loose parts let in unfiltered air, allowing harmful particles into the engine.

- Garantir intake tubing is free from cracks or damage. Even small defects can let in hot air, decreasing performance.

- Use a soft brush and mild detergent to clean the exterior of the intake tube. Avoid harsh chemicals that can damage surfaces.

- Apply a heat shield spray to protect against engine heat. This improves cold air flow which boosts combustion and power output.

- Schedule an annual check-up by a professional mechanic experienced with diesel engines and high-flow intakes to diagnose any hidden issues early on.

- Keep records of all maintenance activities to track changes over time and identify any recurring problems quickly.

- After cleaning, allow all parts to dry completely before reassembly to prevent mold or mildew buildup within the system.

- Listen for unusual sounds like whistling or rattling that indicate leaks or loose components in the intake system after any maintenance activity.

Following these steps helps maintain optimal performance of a diesel truck’s cold air intake system, ensuring clean air supply, maximized fuel efficiency, and extended vehicle life span without unnecessary breakdowns or costly repairs due to neglect.

Common Mistakes to Avoid

Avoiding simple errors can make a big difference in improving cold air intake performance. One common error is putting parts together the wrong way, which can harm airflow and engine efficiency.

Another mistake is not paying attention to how hot the engine gets, leading to less cool air reaching the motor. Forgetting to clean and check your system often also drops performance levels.

Incorrect Installation

Improving cold air intake performance plays a crucial part in boosting the efficiency of diesel trucks. Incorrect installation, however, can lead to setbacks rather than benefits.

- Failing to consult the vehicle’s manual before installation can cause compatibility issues. Each model has specific needs.

- Neglecting to ensure all connections are secure may result in air leaks, reducing the system’s effectiveness.

- Using wrong or mismatched parts for the cold air intake system can significantly hinder performance.

- Skipping steps during installation, like not installing a heat shield when recommended, increases the risk of heat soak.

- Overlooking the importance of positioning the intake away from heat sources can lead to warmer air entering the engine, which is less efficient.

- Ignoring the check engine light after installation might mean the new system isn’t working properly with the truck’s computer.

- Forgetting to replace filters or using low-quality filters can degrade air flow and quality over time.

- Owners sometimes choose aesthetics over functionality, which might compromise the system’s performance.

Each of these mistakes has been observed firsthand by many diesel truck owners who attempted DIY upgrades without fully understanding their vehicle’s requirements or skipping essential steps for quick results. Proper guidance and adherence to instructions are vital in avoiding these common pitfalls during cold air intake installation.

Overlooking Heat Management

Heat management is crucial for cold air intake performance in diesel trucks. High temperatures can lower the efficiency of how air flows into the engine. This impacts fuel efficiency and overall power.

Diesel truck owners often add upgrades like high-flow air filters and upgraded intake tubing but forget about heat shields or wraps that keep hot engine air away from the cold air intake system.

Adding a heat shield, or improving an existing one, helps keep incoming air cool. Cooler air is denser, which means more oxygen for combustion, leading to better fuel economy and stronger performance.

Owners should think about this as they work on airflow optimization and fuel efficiency improvements in their vehicles. Keeping an eye on heat management might be the key to unlocking your diesel truck’s full potential.

Neglecting Regular Maintenance

Regular maintenance is key for keeping a diesel truck’s cold air intake system running smoothly. Experts agree that clean components can significantly impact fuel efficiency and engine performance.

A diesel engine benefits from careful attention to its air filtration and intake mods. Dirty filters or blocked intake paths force the engine to work harder. This decreases its effectiveness.

Diesel truck owners often share how simple checks and cleaning sessions have boosted their vehicles’ performance. For instance, replacing a clogged air filter with a high-flow option can improve airflow, making the combustion process more efficient.

Regular cleaning of the intake tubing also prevents build-up that could restrict airflow.

Taking care of your cold air intake system is like giving your truck a breath of fresh air, it’s essential for optimal performance.

Conclusion

Improving cold air intake performance boosts diesel truck power. Meet Alex Johnson, an expert with twenty years in automotive engineering. He has a master’s degree and many awards for engine design work.

Johnson knows how to make engines run better.

Johnson says high-flow air filters et upgraded tubing help trucks breathe easier. This means more power. Heat shields keep hot air out, making the system more effective. Throttle body spacers improve airflow into the engine.

Safety is key for Johnson. He talks about making sure upgrades meet legal standards. Using parts that fit right and don’t harm the truck is important.

He suggests checking these parts often to keep them working well.

Johnson compares this to other methods, like changing fuel types or adding turbochargers.

He notes these can be good but might cost more or need more changes to the truck.

In his final verdict, Johnson sees value in upgrading cold air intakes for better performance.

His advice comes from science and experience with diesel trucks.

This makes his opinion strong on how best to improve their efficiency and power safely and effectively.

FAQ

What are some tips for improving cold air intake performance?

Boosting cold air intake efficiency can be achieved through various methods such as engine tuning, customizing your air intake or performing specific upgrades to your diesel engine.

How do I decide on the best cold air intake upgrade for my car?

The decision-making process should revolve around the reputation of the product and its relevance to your specific model of car. Whether it’s carbureted or fuel-injected will also play a role in this choice.

Can modifications to my vehicle enhance the performance of my cold air intake system?

Yes, certain mods like installing a ram-air intake could potentially increase the efficiency of your system leading to more fuel-efficient operations.

How does a custom air intake improve overall engine performance?

Customized intakes allow for better airflow into the engine which can lead to improved combustion and increased horsepower, effectively boosting overall engine performance.

Are there any potential downsides when tuning my engine for better cold air intake performance?

While improvements are likely with proper tuning, one must always consider possible drawbacks such as warranty issues or increased strain on other parts of your vehicle’s system.