Installing up-pipes and Y-pipes on a camion diesel is like giving it a breath of fresh air. These parts play a big role in how well the engine works. They help with power and keep things running smoothly.

To start, this means getting ready by having all the right tools and making sure you stay safe. Gloves and glasses are must-haves to avoid any injuries.

The process has several steps that need care and skill. First, take out the old pipes carefully not to damage anything else. Next, put in the new up-pipes followed by the Y-pipes, making sure they fit just right.

It’s also important to check every connection for leaks which could harm your truck’s engine if left unfixed.

After everything is in place, it’s time to see how well your truck performs with its new parts. This upgrade can improve how your diesel runs, offering better power or more smoothness when driving.

Ready to give your truck an upgrade? Let’s get started!

Indice dei contenuti

TogglePreparazione per l'installazione

Getting ready to install those up-pipes and Y-pipes starts with gathering the right tools. You’ll need wrenches, screwdrivers, and a good jack stand to lift your truck safely.

Required Tools and Equipment

Installing up-pipes and Y-pipes on your diesel truck enhances its exhaust system. This upgrade boosts performance and engine tuning. Here’s a list of tools and equipment you’ll need:

- Ratchet set – You’ll use this to remove and tighten bolts.

- Wrench set – Some spots are too tight for ratchets, so wrenches are a must.

- Cacciaviti – These help in removing clamps or adjusting parts.

- Jack stands – They keep your truck lifted safely while you work underneath.

- Torque wrench – It ensures all bolts are tightened to the manufacturer’s specifications.

- Pipe cutter – You might need to trim some pipes for a perfect fit.

- Deburring tool – This smooths out any sharp edges after cutting the pipes.

- Gaskets or sealant – They prevent leaks at connection points between pipes.

- Gloves – Protect your hands from sharp objects and dirt.

- Safety glasses – Keep your eyes safe from debris.

Each item plays a crucial role in the installation process, ensuring safety and precision in fitting up-pipes and Y-pipes into your truck’s sistema di scarico for improved turbocharger integration, emission control, and exhaust flow optimization.

Precauzioni di sicurezza

Safety comes first, especially when working on DIY up-pipe and Y-pipe installation for your diesel truck. It’s not just about getting the job done but also ensuring you do it safely.

- Always wear occhiali di sicurezza to protect your eyes from flying debris or dust.

- Use gloves to keep your hands safe from sharp edges and hot surfaces.

- Make sure the vehicle is securely lifted on cavalletti per martinetti before starting any work underneath it. Never rely on just a jack.

- Disconnect the battery to prevent any electrical shocks or accidental shorts while handling the sistema di scarico.

- Mantenere un fire extinguisher nearby in case of any sparks leading to fires.

- Lavorare in un area ben ventilata to avoid inhaling harmful fumes from the exhaust or chemicals used during the installation process.

- Clear the work area of any flammable materials to reduce fire risks.

- Follow all instructions carefully, step by step, to avoid mistakes that could damage your truck or cause personal injury.

- Check all tools before using them to ensure they are in good condition and suitable for the job at hand.

- If you’re not sure about a step in the installation process, seek advice from someone experienced or consult professional help rather than guessing.

Taking these precautions seriously will help keep you safe while you enhance your diesel truck’s performance with new up-pipes and Y-pipes.

Vehicle Setup and Pre-Installation Checklist

Getting your diesel truck ready for up-pipe and Y-pipe installation is crucial. It sets the stage for a smooth custom exhaust setup process. Here’s how to get things in order:

- Park the truck on a flat, stable surface to ensure safety while working underneath it. Make sure the parking brake is firmly set.

- Gather all necessary tools and equipment before starting. You’ll need wrenches, sockets, screwdrivers, and possibly a jack with jack stands if you need to lift the vehicle for better access.

- Indossare protective gear like gloves and safety glasses to keep yourself safe from sharp edges and debris.

- Disconnect the battery to prevent any electrical shocks or unintended vehicle movements during the installation.

- Check that you have all parts of the new up-pipes and Y-pipes kit. Missing pieces can halt your progress.

- Inspect the area around the old sistema di scarico for any signs of wear or damage that could affect the new installation.

- Utilizzo penetrating oil on bolts and nuts that will be removed. This step can save time by making them easier to loosen.

- Have a buddy help you with lifting and holding heavy parts during removal and installation.

- Keep your phone or camera handy to take pictures of how things are connected before removing them. These shots can guide you when putting in new pipes.

From my experience, following these steps makes fitting new up-pipes and Y-pipes far less stressful. Each point ensures you’re not just ready but also safe throughout the project, turning this DIY task into an achievable weekend job for any diesel truck owner looking to enhance their vehicle’s performance exhaust fitting.

Processo di installazione passo dopo passo

Il installation process kicks off by taking out the old pipes. Grab your wrench and get ready to loosen them up. Next, it’s time to put in the new up-pipes. Make sure you line them up just right before tightening them into place.

After that, fitting the Y-pipes follows a similar drill: align, insert, and secure with clamps for a snug fit. Making sure everything is tight and lined up perfectly is key for a smooth setup.

Removing the Old Pipes

Start by cooling your truck down. You don’t want to burn your hands. Get your tools ready: wrenches, screwdrivers, and a pipe cutter might be needed. Wear guanti e occhiali di sicurezza to protect yourself.

Safety first, always turn off the engine and let it cool before you start.

Taking out the old pipes is straightforward but demands care. Loosen the clamps that hold the pipes tight. Then gently wiggle them free from their connections. Sometimes they stick because of rust or dirt so tap lightly with a hammer if you must.

You may need to cut old pipes if they won’t budge. Do this carefully to avoid damaging other parts of your sistema di scarico.

This process shows how up-pipe and Y-pipe installation starts with patience and attention to detail.

Installing the Up-Pipes

Fitting new up-pipes in a diesel truck means dealing with the engine’s exhaust flow. This step is crucial for custom exhaust setups and making sure your vehicle runs smoothly. First, you need to remove any parts blocking access to the up-pipes location.

This might include taking off heat shields or other components. Use wrenches and sockets to loosen bolts carefully. Handling these tools correctly prevents damage to your truck’s parts.

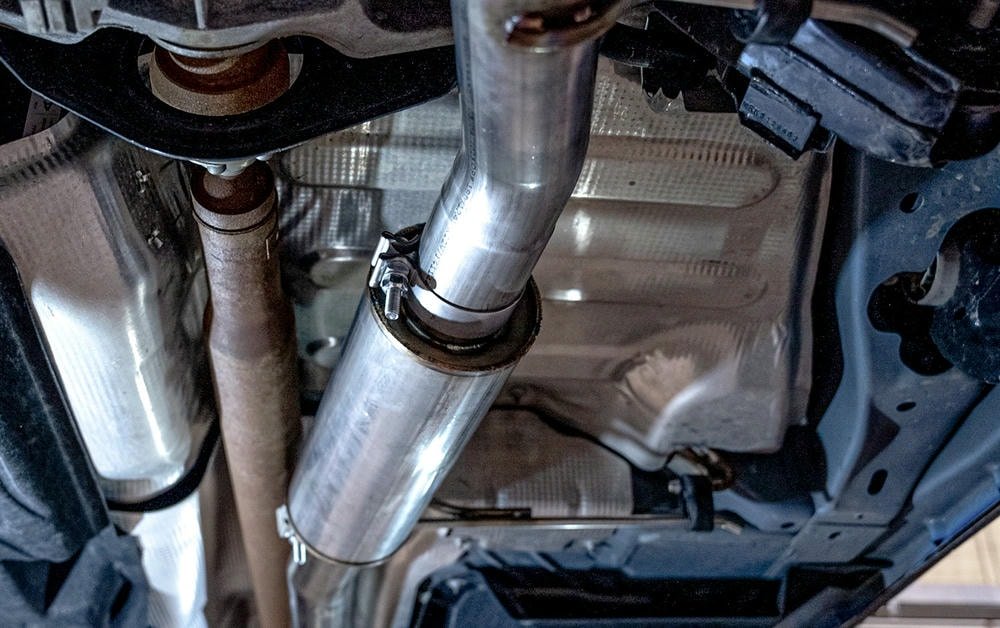

After clearing the way, align the new up-pipes with the manifold and turbo flange. It’s all about precision here; a misalignment can cause leaks or affect performance. Tighten all connections securely but don’t go overboard — over-tightening can strip threads or break bolts.

I’ve seen many folks rush this part, only to face problems later on.

I recall once helping a friend install his up-pipes; we made sure each bolt was snug before fully tightening them in a cross pattern for an even seal. Taking our time paid off, as he noticed immediate improvements in his powerstroke’s exhaust flow and turbo response after installation was complete.

Installing the Y-Pipes

Installing the Y-pipes starts after setting up the up-pipes. First, lift the Y-pipe into place carefully. Line it up with the sistema di scarico‘s other parts. Use a wrench and socket set to attach it securely.

Make sure all connections are tight but avoid over-tightening which can cause damage.

Next, check how the Y-pipe fits with nearby parts. Adjust if needed to make sure nothing touches or rubs against each other. This step helps prevent future problems in your diesel truck’s exhaust system.

Finally, double-check all clamps and bolts one more time for safety before moving on to securing connections and clamps as outlined in your guide on DIY exhaust mods for powerstrokes.

Securing Connections and Clamps

After installing the up-pipes and Y-pipes, it’s crucial to secure their connections well. This step ensures no leaks or loose parts. Use a wrench to tighten the clamps and bolts firmly but not too hard.

Over-tightening can strip the threads or break the clamps. Make sure each connection is snug and check them with your hand for any movement.

Next, inspect all connections visually. Look for gaps that might cause exhaust leaks. You should also listen for hisses or unusual noises when starting your diesel truck after installation.

These sounds could mean air is escaping from somewhere it shouldn’t be. Address these issues right away to avoid damage to your new exhaust system setup.

Regolazione per un corretto montaggio e allineamento

After installing the up-pipes and Y-pipes, ensuring they fit right is crucial. Check every joint and connection. Use a level tool to see if pipes align correctly. Misalignment can cause trouble later.

If something looks off, loosen the clamps or bolts just enough to adjust. Then, tighten them back when everything lines up well.

Ensuring proper alignment prevents leaks and improves performance. Start your diesel truck and listen for any unusual sounds from the exhaust system. Noises may mean there’s a gap or misfit somewhere.

Go back and check all connections again if you hear anything odd. Getting this step right saves time and avoids future issues with your truck’s exhaust system performance.

Considerazioni successive all'installazione

After you put in the new pipes, it’s time to check your work. Make sure there are no leaks and that everything runs smoothly with your exhaust and turbo systems.

Checking for Leaks

To check for leaks after installing up-pipes and Y-pipes, start the truck and let it run. Look, listen, and feel around the pipes and connections. Use a flashlight to see better under the truck.

Se si sente un sibilo o si vede del fumo, potrebbe esserci una perdita. Alcuni usano acqua saponata sulle articolazioniLe bolle indicano la presenza di perdite.

Una piccola falla può far affondare una grande nave.

Le perdite compromettono le prestazioni e possono danneggiare il vostro motore o sistema di scarico con il passare del tempo. Se si riscontrano perdite, stringere i morsetti o i raccordi allentati. A volte le parti devono essere riallineate per ottenere un accoppiamento perfetto.

Mantenere tutto ben saldo assicura al motore un funzionamento regolare e una durata maggiore.

Prova delle prestazioni di turbo e scarico

Dopo aver installato i tubi montanti e i tubi a Y, Controllo delle perdite è fondamentale. In questo modo si assicura che lo scarico Il sistema del vostro camion diesel funziona giusto. Un modo semplice per verificarlo è far girare il motore e ascoltare eventuali sibili o scoppiettii che indicano la fuoriuscita di aria dove non dovrebbe.

Inoltre, con le mani protette da guanti, tastare i giunti e le connessioni per individuare eventuali fuoriuscite d'aria.

Next, Prova delle prestazioni del turbo e dello scarico aiuta a vedere se c'è un miglioramento. Potreste notare che il vostro camion funziona in modo più fluido o ha una potenza migliore. Un buon metodo è quello di utilizzare un manometro per misurare la pressione in uscita dal turbo.

Se i valori sono superiori a quelli precedenti, significa che l'installazione è stata un successo. L'osservazione dell'efficienza del carburante può anche fornire indizi sul buon funzionamento dei nuovi tubi con il sistema del veicolo.

Risolvere eventuali problemi di installazione

Se si verificano problemi con l'installazione del tubo di aspirazione e del tubo a Y, è bene mantenere la calma. I problemi sono spesso dovuti a collegamenti allentati o disallineamenti. Controllare che ogni morsetto e bullone sia ben saldo.

Utilizzare un Chiave dinamometrica per ottenere la giusta tenuta, evitando perdite o rumori.

Le perdite sono un problema comune dopo installazione di sistemi di scarico. Se si sospetta una perdita, ascoltare il sibilo quando il motore gira. Si può anche sentire l'aria che fuoriesce dalle connessioni. Se le perdite vengono riparate tempestivamente, si evitano problemi più gravi in seguito.

Per i problemi più difficili, non esitate a chiedere aiuto a proprietari di camion diesel più esperti, online o di persona. La condivisione delle esperienze può portare a facili soluzioni e a nuovi trucchi per migliorare le prestazioni.

Conclusione

John Carter, un meccanico esperto con vent'anni di riparazioni diesel alle spalle, offre una panoramica approfondita sull'installazione di tubi montanti e tubi a Y. Il suo background comprende una laurea in tecnologia automobilistica e numerosi premi per l'innovazione dei motori.

Conosce a fondo i sistemi di scarico.

Carter sottolinea che una corretta installazione impatta sull'efficienza del carburante e potenza negli autocarri diesel. La scienza alla base? A flusso di scarico più fluido riduce la contropressione, aumentando le prestazioni del motore.

Egli sottolinea anche la sicurezza e l'etica. Gli installatori devono seguire i codici per garantire che i carrelli siano conformi standard di emissione. Un lavoro onesto protegge l'ambiente e mantiene le strade sicure per tutti.

Per l'uso quotidiano, Carter suggerisce controlli regolari dopo l'installazione per individuare tempestivamente le perdite. I proprietari di autocarri devono prestare attenzione ai cambiamenti nel suono dello scarico, segno di problemi.

Confrontando questi tubi con gli altri presenti sul mercato, ne rileva la durata superiore, ma cita i costi più elevati come un aspetto negativo. Tuttavia, considerando i vantaggi in termini di longevità e prestazioni, ne vale la pena.

L'ultima parola di John Carter? I tubi montati e i tubi a Y offrono un valore solido per i proprietari di autocarri diesel che desiderano aumentare le capacità del proprio veicolo in modo sicuro ed efficace.

Domande frequenti

Qual è la procedura passo-passo per l'installazione di un tubo a monte e di un tubo a Y?

Il processo di installazione di tubi montanti e tubi a Y prevede diverse fasi, tra cui la rimozione del vecchio sistema di scarico, il montaggio dei nuovi tubi alla testata del veicolo e il loro fissaggio in posizione. Si tratta di una parte Sistema di scarico completo installazione.

Questa guida fornisce consigli pratici su come montare tubi montanti e tubi a Y?

Sì, la nostra Guida all'installazione di tubi di risalita e tubi a Y offre istruzioni chiare con passaggi praticabili. Incoraggiamo anche il supporto dei colleghi, in modo che i lettori possano condividere i loro consigli o le loro esperienze durante il processo di installazione.

Posso utilizzare questa guida anche se non ho familiarità con il linguaggio tecnico relativo ai sistemi di scarico?

Assolutamente! Sebbene utilizziamo un certo gergo relativo ai sistemi di scarico per autenticità, puntiamo alla brevità e alla chiarezza delle nostre spiegazioni. In questo modo è più facile per tutti capire come installare i tubi montanti e i tubi a Y.

Are there any special tools needed for this type of exhaust system installation?

Typically you’ll need standard auto repair tools like wrenches and screwdrivers; however, specific requirements may vary depending on your vehicle model or type of pipes being installed.