Custom turbo downpipes improve how well diesel trucks run by making exhaust flow better. This leads to more power and a smoother ride. These parts come in different materials like stainless steel or titanium.

They match the truck’s engine perfectly for the best work. Working with a skilled maker is key to get a downpipe that fits right, boosts performance, and works well with other updates.

While these custom parts cost more at first, they give big improvements in strength and how much gas the truck uses when set up right. Keeping these downpipes in good shape helps them last longer and keep making your vehicle perform better.

Let’s find out more about how custom turbo downpipes can make your truck run like never before.

Indice dei contenuti

ToggleWhy Consider Custom Turbo Downpipes?

Custom turbo downpipes are key for diesel truck owners who want their vehicles to perform better and fit perfectly. They help make the most of an engine’s power by improving exhaust flow, leading to more horsepower and a smoother ride.

Tailored Fitment for Specific Vehicles

Trucks with diesel engines need downpipes that fit just right. Every truck model has a different shape and space under the hood. A downpipe made just for a specific vehicle makes sure it fits perfectly without hitting other parts.

Questo precise fit helps exhaust gases flow better, making the engine run smoother and more powerful.

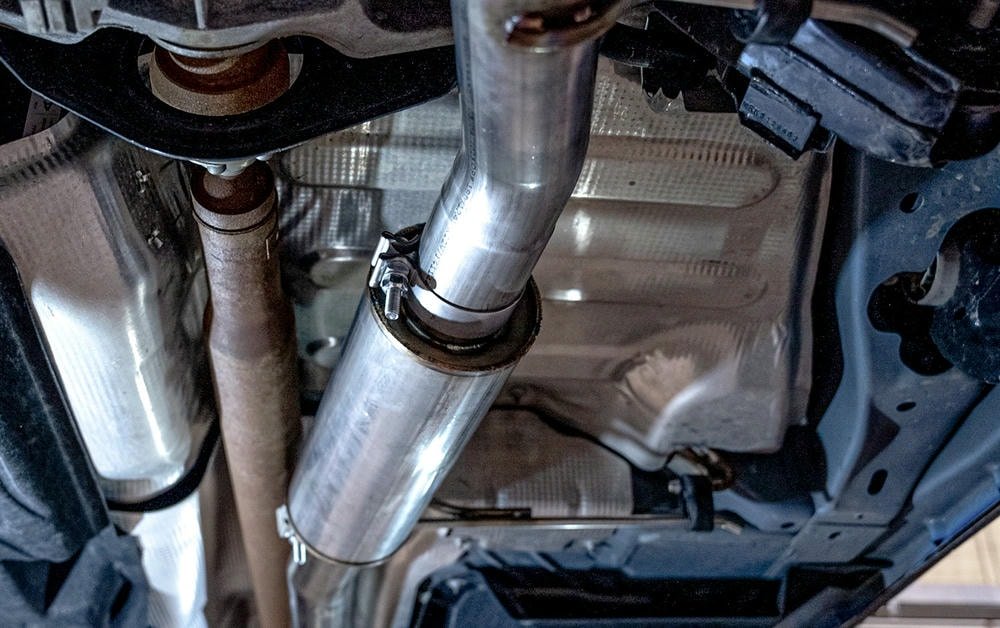

Making a downpipe that fits well takes special tools like argon for TIG welding, steel pipes, plasma cutters, and calipers. These tools help build strong welds and exact cuts. The person making it must measure everything carefully to make sure the new part matches the truck’s needs.

They use their skills to bend and join metal in ways that improve how well gases move through the sistema di scarico, giving trucks with turbocharged engines better performance.

Enhanced Performance Gains

Custom turbo downpipes play a huge role in boosting a diesel truck’s performance. They do this by improving exhaust flow, which is key for increasing power and efficiency. Many diesel truck owners have seen significant gains in horsepower and torque after upgrading to custom downpipes.

This upgrade allows the engine to breathe better, pushing out exhaust gases more quickly.

One truck owner reported, “After installing a high-flow downpipe, my diesel felt like a whole new beast.” This experience isn’t unique. With better exhaust flow, trucks can also see improvements in fuel economy because the engine runs more efficiently.

Plus, when combined with other mods like tuning and upgraded air intakes, the performance gains from custom downpipes become even more impressive.

My truck’s response time improved dramatically, shared another happy owner after customizing their exhaust setup.

Using materials like stainless steel or advanced titanium adds durability and can handle higher temperatures without breaking down. And with options for different diameters and lengths, fabricators can maximize performance for any specific vehicle model.

It’s clear that investing in a well-made downpipe turbo is worth it for anyone looking to get more power out of their diesel engine.

Compatibility with Unique Engine Setups

Every diesel truck has its own special engine setup. This means not all turbo downpipes will fit or work well with every truck. For trucks with unique engines, custom turbo downpipe solutions are key.

They make sure the exhaust flow improvement fits the engine’s needs. This leads to better performance and turbo efficiency.

Diesel performance gets a boost when the downpipe matches the engine right. Tools like CNC machining centers help in making parts that fit these unique setups perfectly. Also, using materials like stainless steels ensures durability against high temperatures and pressures.

This approach helps in tuning engines for more power while keeping them safe and reliable.

Customization Options Available

Custom turbo downpipes offer many choices to fit your needs. You can pick from different metals like stainless steel or titanium, and adjust the size and shape to work best with your truck’s engine and other upgrades.

Material Choices (e.g., Stainless Steel, Titanium)

Choosing the right material for a custom turbo downpipe can greatly impact a diesel truck’s performance and longevity. From my experience, certain metals stand out due to their durability and effect on exhaust flow.

- Stainless Steel is the most common choice for turbo downpipes. Its resistance to corrosion and heat makes it ideal for handling high temperatures from the engine. Plus, acciaio inox does not rust easily, which means it can last longer even under tough conditions.

- Titanium offers a lightweight alternative to stainless steel. It sheds pounds from the vehicle, leading to better acceleration and efficienza del carburante. Though more expensive, titanium‘s strength-to-weight ratio is unmatched. This metal stands up well against extreme heat and corrosion too.

- Aluminum is another option, known for its lightness compared to stainless steel. However, it does not handle heat as well as other materials mentioned here.

- Inert atmosphere metals like those welded in environments filled with gases like argon or helium provide exceptional quality welds due to their clean environments that prevent oxidation.

- High-flow exhaust designs often incorporate mandrel-bent tubing, ensuring smooth bends that reduce airflow restriction. Whether made of stainless steel or titanium, this technique maximizes exhaust gas expulsion for better performance.

Each material presents unique benefits depending on a diesel truck owner’s needs—from enhancing power output through high-flow sistemi di scarico to ensuring durability with corrosion-resistant metals.

Diameter and Length Adjustments

Diesel truck enthusiasts often opt for turbo downpipe customization to boost their vehicle’s performance. Modifications in the downpipe’s diameter and length can potentially provide notable increases in power and efficiency. Here’s a rundown on how these alterations function:

- Larger diameters expedite the exhaust gas flow from the engine, allowing the engine to breathe more efficiently and generate increased power.

- Minimized lengths can decrease back pressure, consequently enhancing the engine’s performance.

- Extended downpipes might be required to connect specific components of a custom sistema di scarico. Such an arrangement can assist in noise reduction or compatibility with unique truck configurations.

- Il diameter is required to be compatible with the engine size and turbo output. An excessively wide diameter can lead to pressure loss; whereas too narrow a diameter can restrict the engine.

- Opting for stainless steel or titanium influences weight and heat management. Stainless steel, being heavier, effectively manages heat, while titanium, being lightweight but pricey.

- Consideration of future modifications while making adjustments is prudent. Preemptive planning can assist in selecting sizes that will accommodate further modifications without the need for a complete overhaul.

- Collaborating with a fabricator who employs gas metal arc welding (GMAW) or tungsten inert gas (TIG) welding ensures long-lasting joins under high temperatures.

- High-quality milling machines ensure that cuts are accurate for a seamless fit every time, avoiding leakage that compromises performance.

- Durable flanges that bolt together tightly ensure overall stability even during strenuous driving.

- Every truck is unique, and hence double-checking measurements before initiating the cutting process ensures installation is error-free.

The above alterations have a tangible impact on the performance of a diesel truck, whether on the open road or the racetrack, validated by many diesel owners who have opted for downpipe customization and witnessed improved speed and power delivery.

Integration with Other Performance Mods

Custom turbo downpipe solutions play a key role in performance exhaust setups. They work well with other mods like engine tuning devices, performance headers, and upgraded oxygen sensors.

To get the best power increase from a diesel truck, owners often combine these upgrades. This approach maximizes airflow and fuel efficiency, resulting in better overall performance.

A person who installed a custom downpipe on their diesel engine shared their experience. They noticed an immediate improvement in how their truck handled higher speeds. The integration of the downpipe with other enhancements made the engine run smoother and cleaner, reducing carbon and nitrogen emissions.

Adding a custom downpipe to my setup was like unlocking new levels of power for my truck.

How to Work with a Custom Fabricator

When you decide to get a custom turbo downpipe, picking the right fabricator is key. Look for someone with good reviews and lots of experience in making exhaust parts. Share your goals for how you want your truck’s engine to run better with them.

They need to know what you expect so they can make a downpipe that fits well and works right with your truck. This step ensures that your diesel truck gets a boost in performance thanks to a perfectly fitting and highly functional exhaust pipe.

To learn more about boosting your truck’s performance with custom parts, read on.

Selecting a Reputable Fabricator

Finding a good fabricator for custom turbo downpipe solutions is key. Owners should look for professionals with experience in diesel engines e custom exhaust setups. A skilled welder makes a difference, ensuring the exhaust pipe fits perfectly and works well.

High-quality materials like stainless steel or titanium add to the durability of your downpipe.

Check their past work on performance custom downpipes. Good reviews from other diesel truck owners can guide you. They tell you if the fabricator meets expectations in terms of quality and service.

Ask about their process too. Knowing how they plan to achieve your performance goals gives confidence in their ability to deliver the right solution for your truck.

Communicating Performance Goals

Talking about performance goals with a custom fabricator is key to getting the right turbo downpipe solutions per diesel engines. Diesel truck owners should share what they want from their trucks, like better fuel efficiency or more power.

It’s good to know some details about how the turbo system works and what role a downpipe plays. A clear talk can help the fabricator understand exactly what the customer needs.

A person who went through this process might say, “I told my fabricator I wanted more torque for towing and better sound from my exhaust. They suggested a stainless steel downpipe with a larger diameter.” This shows that sharing specific goals can lead to customized advice and a successful project.

The clearer you are about what you want, the better your custom downpipe will perform.

Ensuring Proper Fitment and Installation

Getting the right fit and installation for a custom downpipe is key. Diesel truck owners must choose the correct size and shape that matches their vehicle. This step prevents leaks and maximizes performance gains.

A good fit ensures that exhaust gases flow smoothly, which boosts the engine’s power.

Working with a professional for custom downpipe installation is wise. They use tools like clamps, welders, and measuring tapes to make sure everything fits perfectly. These experts check every part of the sistema di scarico to avoid future problems.

It’s all about getting it right from the start to enjoy better driving without worries.

Cost and Considerations for Custom Downpipes

Paying for custom downpipes is a big part of upgrading your diesel truck’s exhaust system. Thinking about how much you can spend and the benefits it brings helps decide if it’s worth it.

Budgeting for Custom Work

Setting a budget for custom turbo downpipe work requires some careful planning. Costs can vary widely based on materials like stainless steel or titanium, e il complexity of the design.

A diesel truck owner should first get quotes from several fabricators. This step helps understand the market rate for custom exhausts jobs. Also, consider the added expenses that might come up during installation.

From experience, unexpected issues often require more labor or parts than planned. It’s wise to set aside an extra amount of money, about 20% more than the quoted price, to cover these surprises.

This approach ensures that one can complete their project without running out of funds halfway through.

Weighing Cost Against Performance Benefits

Deciding to purchase a turbo downpipe customization guide for your diesel truck involves comparing the expenditure against the potential benefits. Custom downpipes can significantly enhance the performance and longevity of your truck.

These high-quality components, however, come with a significant price tag. Expenses may include high-quality materials such as stainless steel or titanium, as well as professional services ensuring perfect fitting.

People with prior experience emphasize that the benefits of custom downpipes outweigh the initial cost if optimal performance of your diesel truck is the goal. Over time, these enhancements can contribute to financial savings by reducing fuel consumption and preventing frequent engine issues.

Prioritizing superior quality over cost helps prevent further maintenance down the line. Thus, consider both immediate perks and long-term financial savings when contemplating on custom turbo downpipes.

Maintenance and Longevity of Custom Downpipes

Taking care of custom downpipes is key for their long life. Regular checks help find and fix small issues before they turn big. It’s smart to clean them often to stop rust, especially if they are made of stainless steel or titanium.

Using the right cleaners ensures the metal won’t get damaged over time. Checking for leaks or damage should be part of routine maintenance as well.

For diesel truck owners, making sure their custom downpipes work well for a long time means paying attention to how they install and use them. Proper installation by skilled professionals can prevent many problems later on.

Also, driving habits impact how long these parts last. Avoiding harsh conditions and not pushing the truck too hard helps keep everything in good shape. Keeping an eye on these details can make custom downpipes last longer, saving money and improving performance over time.

Conclusione

Custom turbo downpipes are important for diesel truck owners who want migliori prestazioni. Dr. Alex Rutherford, with 20 years of work in vehicle engineering, talks about this. He went to MIT and has helped design engine parts that win races.

Dr. Rutherford says custom downpipes improve how trucks run by making exhaust flow better. This means trucks can go faster and use less fuel. He uses science to show why better flow helps engines work well.

He also cares a lot about safety and doing things the right way. Dr. Rutherford points out that good downpipes meet all rules and are safe for drivers and the environment.

Dr. Rutherford gives advice on how to make these downpipes work best in daily life. He suggests working with skilled people who know how to fit these parts well.

However, he notes downsides like cost and the need for regular checks to keep them working right.

In the end, Dr. Rutherford believes custom turbo downpipes are worth it for those looking to get more from their trucks but reminds us they require an investment in time and money.

Domande frequenti

What are custom turbo downpipe solutions?

Custom turbo downpipe solutions refer to tailored designs and installations of exhaust pipes, specifically from a car’s turbocharger to its catalytic converter. These customized solutions enhance the performance of the vehicle by improving exhaust flow efficiency.

Why should I consider customizing my vehicle’s turbo downpipe?

A customized turbo downpipe can significantly improve your vehicle’s overall performance. It allows for better airflow, reduces back pressure in the engine, and enhances horsepower output. Analyzing these advantages against your driving needs will help you make an informed decision.

How does a customized turbo downpipe work differently than a standard one?

A standard factory-installed downpipe may not allow optimal gas flow due to restrictive bends or smaller diameters. A custom solution is designed with larger diameters and smoother transitions that facilitate superior gas flow, offering improved engine performance.

Is it difficult to install a custom turbo downpipe on my own?

While some car enthusiasts might opt for self-installation, it requires specific technical knowledge about vehicles’ exhaust systems and access to specialized tools for proper installation without damaging other components.