Maintaining the exhaust manifold is key to keeping a diesel truck running well. The exhaust manifold, a part that helps the engine’s gases flow out safely, needs regular care. Checks and cleanings prevent big problems later.

This article talks about how to keep an eye on your truck’s exhaust system, fix common issues like leaks or cracks, and choose the best parts for repairs. It also explains why monitoring your engine’s performance can help you spot trouble early.

Read on to learn how to take good care of your diesel truck’s exhaust manifold.

Spis treści

ToggleWskazówki dotyczące rutynowej konserwacji

Keeping your kolektor wydechowy in top shape starts with simple steps. Regularly check for any signs of damage and clean the part to prevent rust and corrosion.

Regularne kontrole pod kątem pęknięć i wycieków

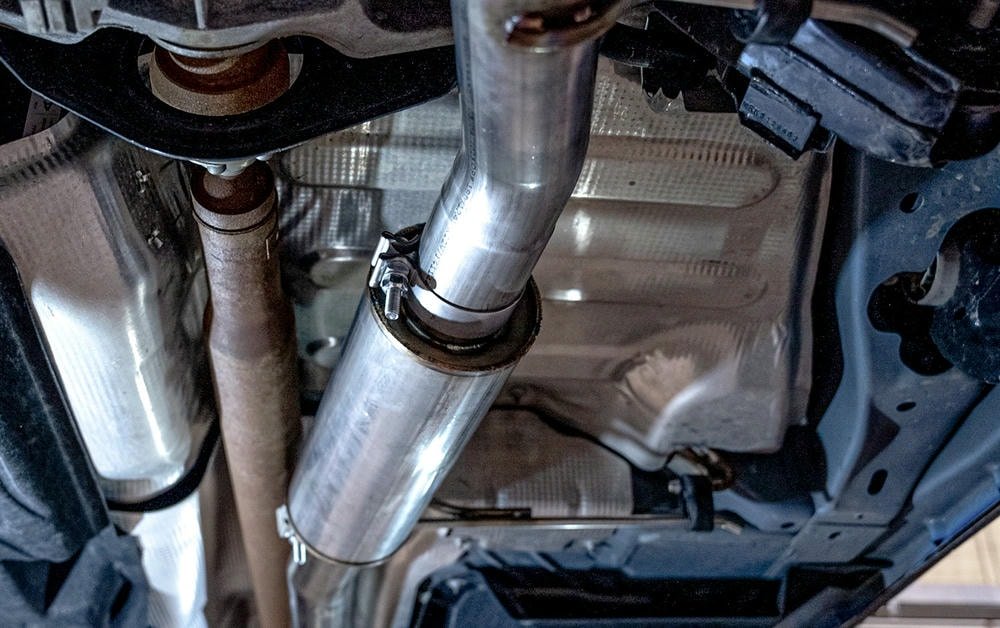

Checking your diesel truck’s exhaust manifold regularly helps catch problems early. This can save you from bigger repairs later. Here’s a guide on how to do it right.

- Start with a visual check of the exhaust manifold. Look for any signs of cracks or leaks. These can happen because of the heat and stress the manifold faces.

- Use a flashlight to help see better. Sometimes cracks are small and hard to spot.

- Feel around for air coming out where it shouldn’t be. Wear gloves for safety. If you find air escaping, that’s a sign of a leak.

- Posłuchaj odd sounds like hissing or tapping when the engine runs. These noises often point to leaks in the manifold.

- Sprawdź bolts holding the manifold in place. They should be tight but not too tight. Use a socket set for this job.

- Look at the gasket between the manifold and engine block for wear or damage. It seals the two parts together, stopping leaks.

- Smell for burning or gas-like odors near the układ wydechowy while the engine is running (but be safe). This smell can mean there are leaks letting fumes out.

I learned these steps from working on my own diesel truck and helping friends with theirs. Keeping an eye on these things has stopped many small issues from turning into big ones.

Cleaning the Exhaust Manifold

Cleaning the exhaust manifold is a key step in keeping a diesel truck running well. It helps the engine run smoothly and reduces emission control problems. Here’s how to do it properly:

- Gather tools needed: This includes gloves, eye protection, a szczotka druciana, ratchet, sockets, and a cleaning solvent.

- Let the engine cool: Never start cleaning while the engine is hot to avoid burns.

- Remove any covers: Use the ratchet and sockets to take off any protective covers on the manifold.

- Inspect for dirt and soot: Look closely at the manifold for signs of carbon build-up or soot.

- Apply solvent: Spray a good quality cleaning solvent directly onto the manifold areas with build-up.

- Scrub with wire brush: After letting the solvent sit for a few minutes, scrub off the grime with a wire brush.

- Wipe clean: Use a rag to remove any loose debris or remaining solvent.

- Sprawdź bolts and gaskets: Look over the bolts and manifold gaskets for signs of wear or damage.

- Tighten bolts if needed: If any bolts are loose, use your ratchet and sockets to tighten them securely.

- Reattach covers: Put back any protective covers you removed earlier.

From personal experience, performing this routine regularly can prevent exhaust leaks i boost overall performance exhaust care. Keeping an eye on corrosion or rust during cleaning can also save on future repairs by catching issues early on. This simple upkeep task ensures that vital parts like oxygen sensors work well and that fuel consumption remains efficient by allowing exhaust gases to escape freely from your diesel engine’s internal combustion chamber.

Checking and Tightening Bolts

Keeping bolts tight on an kolektor wydechowy is crucial for diesel truck owners. It prevents leaks and ensures the engine runs smoothly. Here are steps to follow:

- Locate the exhaust manifold. It’s on the side of the engine, attaching it to the układ wydechowy.

- Gather your tools. You’ll need a klucz dynamometryczny, zestaw gniazd, and possibly a screwdriver.

- Let the truck cool down before you start. Working on a hot engine can cause burns.

- Check each bolt by hand first to see if any feel loose.

- Use the torque wrench and socket that fits the bolts snugly.

- Tighten each bolt in a sequence, not all at once. This helps distribute pressure evenly.

- Refer to the truck’s manual for the exact torque specification needed for each bolt.

- Tighten to the specified torque setting, usually measured in foot-pounds or Newton-meters.

- If any bolt turns freely or doesn’t tighten, it may be stripped or damaged and needs replacing.

- After tightening, double-check each bolt to ensure they’re all secure.

This process should become part of routine maintenance for diesel engines, helping prevent future exhaust system issues like leaks or damage from vibrations and heat stress. Properly securing these bolts keeps everything running as it should, safeguarding against costly repairs down the line.

Monitoring for Signs of Corrosion or Rust

Corrosion or rust on an exhaust manifold can lead to serious problems for diesel truck owners. Spotting these issues early can save time and avoid costly repairs.

- Look closely at the exhaust manifold for any orange or brown spots. These colors suggest rust is forming.

- Use a flashlight to inspect hard-to-see areas. Rust often starts where moisture collects.

- Feel the surface of the manifold with gloves. Rough spots might mean corrosion has begun.

- Smell the engine area while it’s running. A strange odor can indicate leaking gases, which speed up rusting.

- Posłuchaj unusual sounds like hissing or tapping from the układ wydechowy. These noises could signal leaks that let in air and moisture, causing more rust.

- Check for loose or missing bolts around the manifold. Vibrations from loose parts can damage protective coatings, leading to rust.

- Look under your truck after it rains or you wash it. Water should not pool near the exhaust manifold; if it does, find out why.

- Zwróć uwagę na changes in engine performance, such as reduced power or efficiency, which might hint at an exhaust problem related to corrosion.

Diesel truck owners know their trucks work hard and face tough conditions that can cause wear on components like the exhaust manifold. Regular checks help catch corrosion before it gets worse, ensuring the truck runs smoothly and stays reliable on the road.

Najczęstsze problemy i sposoby ich rozwiązywania

Dealing with exhaust manifold problems starts by knowing what often goes wrong, such as leaks or cracks. Tools like wrenches and sealants, alongside parts like high-quality gaskets, play a key role.

Learning how to fix these issues can keep diesel trucks running smoothly. Keep reading to learn more about tackling these common challenges.

Exhaust Leaks

Exhaust leaks are common problems in diesel trucks. These leaks can lead to poor engine performance, higher fuel consumptionoraz danger from exhaust gases entering the cabin. To fix exhaust manifold issues like leaks, one must first find where the leak is coming from.

Sound is a clue; hissing or tapping noises near the exhaust manifold suggest a leak. Using a mechanic’s stethoscope helps pinpoint the noise source more accurately.

A visual check is next. One might see black soot marks on the manifold surface or around gaskets indicating escaping gases. Tightening bolts may solve some issues, but replacing damaged gaskets or cracked manifolds is often necessary.

For serious problems, consulting a professional who understands diesel engine maintenance and exhaust systems upkeep becomes vital.

A small leak today can lead to big problems tomorrow.

Cracks in the Manifold

Cracks in the manifold can lead to big problems for diesel truck owners. These cracks allow exhaust gases to escape before they reach the catalytic converter. This leads to a loss of engine efficiency and higher emissions.

Most often, manifold cracks occur due to extreme temperature changes inside the engine compartment.

A diesel truck owner found this issue first-hand. After noticing a louder than usual engine noise and reduced power, they inspected their manifold. They discovered small cracks that had started to form around the edges where it seals against the cylinder head.

To fix these issues, one needs a detailed inspection with tools like mirrors and flashlights to see hard-to-reach areas clearly. If small cracks are found early, welding might repair them before they grow larger and more costly to fix.

Gasket Wear and Replacement

Gasket wear is common in diesel trucks and leads to leaks. These parts seal the space between the exhaust manifold and the engine block. Over time, they can break down due to heat and pressure.

Diesel truck owners often spot this problem during routine checks or if they notice a decrease in engine performance.

Replacing worn gaskets prevents future leaks. This job involves removing the exhaust manifold, taking out the old gasket, and installing a new one. It’s vital to use wysokiej jakości uszczelki for a lasting fix.

During replacement, tightening bolts correctly ensures everything seals well without causing damage. Owners who have done this themselves say it makes their engines run smoother and reduces chances of further leaks.

Wypaczenie lub zniekształcenie kolektora

Warping or distortion of the manifold often happens due to extreme heat in the diesel truck’s engine. This condition can seriously affect how well the engine runs. The kolektor wydechowy collects gases from multiple cylinders into one pipe.

If it warps, these gases might leak out before they should. This means less power for your truck and possible damage over time.

To fix this issue, owners need to check their manifolds regularly using simple tools like a straight edge and feeler gauge. These tools help find any warping that is hard to see with just eyes.

A warped manifold may require flattening or replacing completely to stop exhaust leaks and restore osiągi silnika. Regular checks and maintenance are key in preventing such problems from affecting your diesel truck’s health.

Zapobieganie przyszłym problemom

To avoid future issues with the exhaust manifold, one must focus on using top-notch gaskets and ensuring all parts fit well. Keeping an eye on how the motor runs will also help spot problems early.

Korzystanie z wysokiej jakości uszczelek i komponentów

Using top-notch gaskets and parts is key in preventing manifold gasket failure. These high-quality materials can handle the heat and pressure from an internal combustion engine better than cheaper options.

They are made to fit perfectly, which keeps leaks at bay. For diesel truck owners, this means less time fixing exhaust manifolds issues and more time on the road.

Choosing the right components involves knowing what works best with your vehicle’s układ wydechowy. Look for gaskets made from durable materials designed for high temperatures. Also, ensure that bolts and other fittings are of good quality to avoid warping or distortion under stress.

This careful selection helps maintain engine tuning and ensures proper exhaust gas recirculation valve function, contributing to a healthier engine and environment.

Zapewnienie prawidłowej instalacji

Ensuring the exhaust manifold is installed correctly is key for diesel truck owners to avoid common problems. This process includes using wysokiej jakości uszczelki and making sure all bolts are properly tightened.

An expert mechanic should handle installation, as they have the right tools like torque wrenches and experience with o2 sensors and head gaskets. They know how tight each bolt should be to prevent leaks or warping.

From personal experience, a small mistake during installation can lead to big issues later. For example, a loose bolt might not seem like a big deal at first, but it can cause an exhaust leak that hurts performance.

Diesel truck owners should check their work after installation by listening for unusual noises or checking for signs of leaks around the manifold area. Proper monitoring of engine performance can also signal if something was missed during installation.

Regularne monitorowanie wydajności silnika

Mając oko na osiągi silnika is key for diesel truck owners. This process involves watching the układ wydechowy, throttle, egr valve, and pistons closely. Good engine performance shows your exhaust manifold is in top shape.

If something feels off, like a drop in power or strange noises, it could point to manifold problems.

Drivers should use tools that read the air injection systems and check compression levels regularly. These tools help spot issues early on before they grow bigger. They also guide you in fixing exhaust manifold issues without guessing.

Regular checks keep big repairs away.

Wnioski

Maintaining and troubleshooting exhaust manifolds is key for diesel truck owners. Experts like Dr. Marcus Allen know this well. Dr. Allen has spent years working with vehicle systems, focusing on exhaust flows in diesel engines.

His work includes teaching and writing about how these systems work and fail.

Dr. Allen explains that regularne kontrole can prevent common problems like leaks or cracks in the manifold. He talks about how cleaning and keeping bolts tight help the system run right.

Using good parts when fixing or replacing things also matters a lot.

He stresses bezpieczeństwo przede wszystkim, always following rules to avoid harm when working on your truck’s exhaust system–and being clear about what you’re doing is vital too.

For everyday use, Dr. Allen suggests watching your engine’s signs closely. This way, you catch issues early before they get worse.

Comparing maintaining your manifold to other care tasks shows its value clearly—doing it right keeps your truck running smoothly and saves money over time by avoiding big repairs.

Finally, Dr. Allen believes strongly in the importance of taking care of your exhaust manifold properly—for both performance and safety reasons—making it worth the effort for all diesel truck owners.

FAQs

What are some common exhaust manifold problems and how can I troubleshoot them?

Common exhaust manifold problems often include leaks which can damage the entire układ wydechowy. You can troubleshoot these issues by inspecting for visible signs of wear or listening for unusual noises that may indicate a leak.

How do I maintain my vehicle’s exhaust manifolds to prevent damage?

Regular maintenance is crucial to keep your exhaust system, including the manifolds, in good condition. This includes regular inspections for any signs of wear or leakage and immediate repair if required.

Can I repair an exhausted manifold myself or should it be done by a professional?

While minor repairs might be possible with a detailed manifold repair guide, it’s recommended to seek professional help due to safety concerns and technical complexities involved in troubleshooting exhaust systems.

Why is upkeep important for my car’s exhaust system?

Exhaust system upkeep is essential as it ensures optimal performance of your vehicle while also preventing potential hazards such as leaks which could lead to more serious mechanical issues.