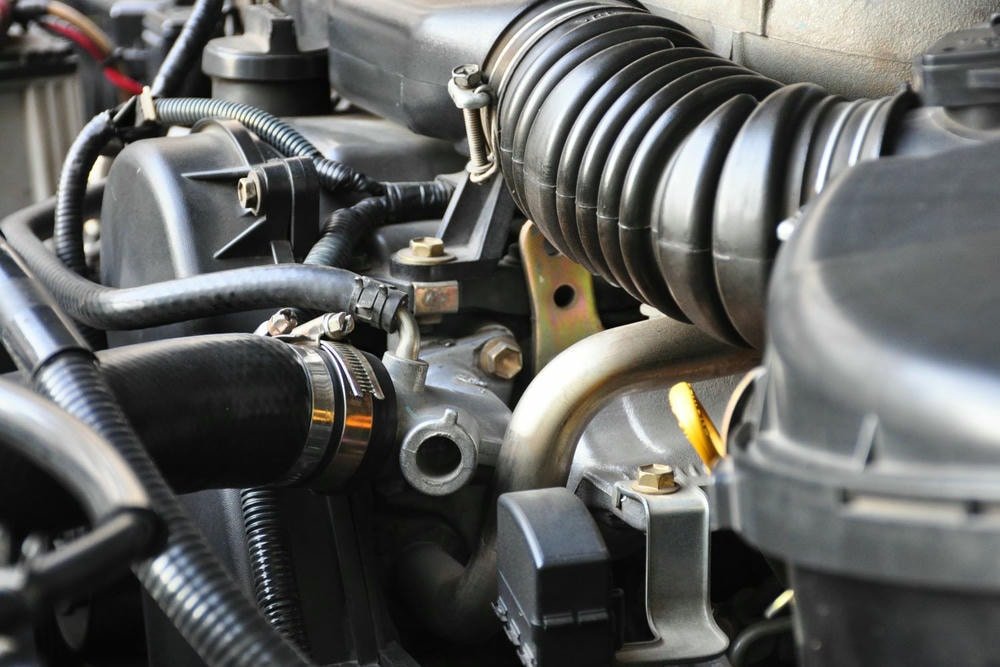

Coolant hose problems in diesel trucks can lead to big issues, like the engine overheating. This article talks about common coolant hose troubles. It covers leaks, cracks, wear and tear, blocks in flow, and overheating.

Diesel truck owners will learn how to spot damage on hoses, replace them when needed, make sure they fit right and stay connected properly. They will also find out how to keep an eye on coolant levels and quality.

Using good hoses and clamps that match their truck helps avoid leaks and keeps the cooling system running smoothly. Replacing old or damaged parts fast is key to protecting the engine.

Regular checks help catch small problems early before they grow bigger. This saves time and money down the road.

Keep your truck running cool ahead.

Table of Contents

ToggleCommon Coolant Hose Problems

Coolant hoses in diesel trucks can face several issues. These problems include leaks, cracks, and blockages that stop the coolant from moving as it should.

Leaks and Burst Hoses

Leaks and burst hoses in a diesel truck’s cooling system can cause big problems. They happen when the hose gets old or damaged. This can lead to loss of antifreeze and overheating, harming the engine.

A driver may first find out about a leak by spotting antifreeze under their truck or seeing the engine temperature go up.

To spot these issues early, one should regularly check hoses for signs of wear or damage. If a hose looks swollen, cracked, or feels too soft, it might be time to replace it. Using high-quality radiator hoses and clamps helps avoid leaks and bursts.

During replacement, ensuring a tight fit is crucial to prevent future leaks. Replacing worn-out parts before they fail saves time and money on auto repair bills later on.

Cracks and Wear

Cracks and wear on coolant hoses are signs of aging or stress. These problems can lead to leaks, reducing the effectiveness of the cooling system in a diesel truck. Over time, exposure to extreme temperatures and chemicals causes hoses to harden and crack.

Diesel truck owners should check their hoses regularly for any signs of wear or damage. Small cracks might not seem like a big deal, but they can grow larger, leading to more serious issues.

To spot these problems early, look at the surface for any visible signs of cracking or splitting. Feel the hose too; it should be firm yet flexible. A brittle hose is likely worn out and needs replacing.

Keeping an eye on these signs helps prevent sudden failures that could overheat the engine.

A stitch in time saves nine.

Coolant Flow Restrictions

Coolant flow restrictions in a diesel truck can cause big problems, like the engine getting too hot. This happens when something blocks the coolant from moving freely through the cooling system.

Common blockages include buildup inside the radiator or hoses, a stuck thermostat that won’t open, or a problem with the water pump not pushing coolant properly. For example, if sediment from old coolant builds up in the radiator tubes, it can slow down how fast coolant flows.

Diesel truck owners might notice their trucks heating up more than usual if there’s a restriction. They can check by looking for reduced flow at the radiator cap when the engine is running.

A quick look at the thermostat and water pump may also show where trouble starts. Fixing these issues early keeps engines safe and prevents damage from overheating.

Overheating Issues

Overheating in diesel trucks can lead to serious damage. It often points to problems with the cooling systems, such as blocked radiators or faulty hoses. Truck owners need to monitor engine temperature closely using tools like OBD-II scanners, which help spot early signs of overheating.

Regular checks can prevent bigger issues.

To fix overheating, one must ensure that the radiator and other components like the thermostat are working well. Also, keeping coolant levels topped up is crucial for engine temperature control.

Replacing old hoses with high-quality options helps maintain proper flow and prevents future overheating incidents in vehicles.

Troubleshooting and Fixing Issues

Finding and fixing coolant hose issues can help keep your diesel truck running well. To learn more about managing these problems, check out the tips on spotting damage, replacing hoses, and making sure everything fits right.

Inspecting Hoses for Damage

Inspecting hoses for damage is crucial in diesel truck care. Diesel engine owners can prevent coolant hose failure by checking their hoses regularly.

- Look for any signs of leaks around the hose ends and where they connect to the car radiator or heater core. Leaks often leave a trail of dried coolant.

- Check if there are any cracks on the surface of the hoses. Cracks can lead to leaks and cooling system failures.

- Feel the hoses to check for any soft spots or areas that seem too hard. These can indicate wear inside the hose, which could lead to bursting.

- Make sure there’s no swelling near the connections or along the hose length. Swelling suggests that the hose might fail soon.

- Look for abrasions or cuts on the exterior of the hoses that could deepen over time, causing a leak.

- Inspect for kinks or bends that restrict coolant flow, leading to overheating issues in your diesel engine.

- Use an obd2 scanner to read engine codes if your truck has an electronic management system; some codes may suggest cooling system issues related to hoses.

- Confirm all clamps are tight and secure but not overly tightened, as this could pinch the hose and cause damage.

- Check for age-related wear; even without visible signs of damage, rubber components like hoses degrade over time and should be replaced every few years based on manufacturer recommendations.

- Monitor your truck’s temperature gauge closely after inspecting hoses. A rise in engine temperature might indicate a problem that wasn’t visible during inspection.

Regular inspections ensure your diesel truck’s cooling system operates efficiently, protecting your engine from overheating and severe damage.

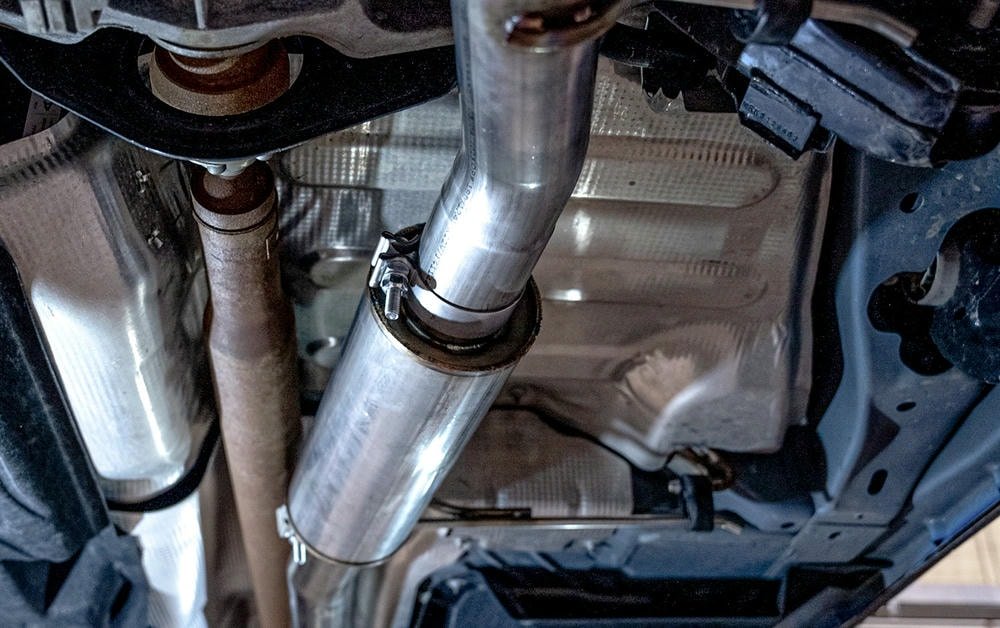

Replacing Worn or Damaged Hoses

Coolant hose problems can lead to big issues for diesel truck owners. Knowing how to replace worn or damaged hoses is key to protecting the engine.

- First, find the right replacement hoses. Look for high-quality options that match your diesel truck’s specifications.

- Gather your tools. You’ll need a screwdriver, pliers, and possibly a utility knife.

- Turn off the engine and let it cool down. This step is important to avoid burns.

- Drain the coolant from your system. Use a container to catch the fluid for proper disposal.

- Locate damaged hoses by checking for leaks, cracks, or signs of wear.

- Remove clamps or connectors holding the old hose in place with pliers or a screwdriver.

- Carefully remove the old hose. You might need to twist or cut it if it’s stuck.

- Compare the new hose with the old one to ensure a proper fit.

- Install the new hose, making sure it sits securely on both ends.

- Reattach clamps or connectors tightly to prevent leaks.

- Refill your cooling system with coolant according to your truck’s manual.

- Start the engine and let it run for a few minutes with the heater on high to remove any air in the system.

13 Check for leaks around new hoses and fittings once everything is back in place.

Use this guide whenever replacing coolant hoses in your diesel truck to keep its cooling system running smoothly and extend its life span

Ensuring Proper Fitment and Connection

Ensuring the right fit and secure connections within a diesel truck’s cooling system is crucial. It prevents leaks that can lead to overheating, engine damage, and increased wear on components like the head gasket, catalytic converter, and oil coolers. Here are steps to guarantee proper fitment and connection of coolant hoses:

- Measure the old hose before buying a new one. Ensure the length and diameter match the original.

- Check for the type of hose needed. Diesel trucks might require specific hoses designed for high pressure or temperature.

- Use quality clamps to secure hoses. Cheap clamps can fail and cause leaks.

- Clean hose ends and fittings before installation. This removes debris that can cause leaks.

- Apply a small amount of lubricant to fittings if necessary. This makes it easier to slide hoses into place without damage.

- Push hoses onto fittings until they reach the marking or stop point.

- Tighten clamps to manufacturer’s specifications but don’t over-tighten as this can cut into the hose.

- After installation, check for kinks or bends in hoses that could restrict coolant flow.

- Run the engine and inspect all connections for leaks.

- Check coolant levels after repairs and top off if needed.

- Monitor temperature gauges while driving, especially during the first few trips after maintenance.

- Schedule regular inspections of cooling system components, including hoses, to catch issues early.

Following these steps helps maintain your diesel truck’s cooling system in top condition, safeguarding your engine from overheating problems and ensuring optimal performance on long hauls or heavy-duty tasks.

Monitoring Coolant Levels and Quality

Monitoring coolant levels and quality is crucial for diesel truck owners. This helps prevent cooling system leaks and protects the engine. Here’s how to do it:

- Check the coolant level every month. Make sure the truck is on a level surface and the engine is cool.

- Open the radiator cap carefully using a rag to avoid burns from steam or hot fluid.

- Look at the coolant in the overflow tank. The liquid should be between the “Low” and “Full” marks.

- Use a flashlight to inspect inside the radiator if needed. You should see coolant near the top.

- Add more coolant if it’s below the acceptable line. Use a mix of 50% water and 50% antifreeze, or as your truck manual suggests.

- Examine coolant color and clarity. It should be bright green, orange, red, or yellow without any dirt or oil mixed in.

- Smell the coolant too. A sweet smell is normal, but a burnt odor could mean problems.

- Replace old or dirty coolant with fresh mix according to your service manual’s schedule.

- Test the coolant with a hydrometer or test strips from an auto parts store to check its freezing point and acidity level.

- Keep records of cooling system maintenance for future reference.

Following these steps ensures your diesel truck’s cooling system works well to avoid overheating issues and engine damage caused by poor-quality or low-level coolantю

Preventing Future Problems

To keep coolant hoses in top shape, stick to a routine of checks and care. Use strong hoses and clips, make sure they fit right, and get them in correctly every time.

Regular Maintenance and Inspections

Keeping a diesel truck running smoothly requires consistent maintenance and inspection of its parts, especially the cooling system. Coolant hoses are vital, as they carry coolant to and from the engine, helping manage the engine’s temperature.

- Check coolant levels every month. This ensures the engine stays cool and helps prevent overheating.

- Inspect hoses for signs of wear or damage. Look for soft spots, cracks, or leaks that could suggest a hose is failing.

- Test the tightness of hose clamps regularly. Loose clamps can lead to leaks and reduced coolant flow.

- Flush the cooling system once a year. This process removes rust and debris that could clog the hoses.

- Replace old or worn hoses with high-quality ones. Choosing good hoses prevents future leaks and overheating problems.

- Monitor engine temperature closely. If it rises quickly, this might indicate a problem with the cooling system, often related to hoses.

- Ensure proper installation of all hoses after checks or replacements. Incorrect fitting can lead to leaks and engine damage.

- Keep records of all maintenance work done on coolant hoses for reference during future inspections.

- Always use recommended types of coolant for diesel engines to avoid damaging hoses and other components of the cooling system.

- Regularly check for updates on hose care specific to your truck’s model, ensuring you follow the latest advice for upkeep.

Using High-Quality Hoses and Clamps

Diesel truck owners know the engine’s health is vital. High-quality hoses and clamps ensure the cooling system works well.

- Choose hoses designed for diesel engines. These handle high temperatures and pressures better.

- Select clamps that are stainless steel. They resist rust and provide a tighter fit.

- Look for hoses with reinforced walls. This prevents bulges and bursts under stress.

- Ensure the hose fits your model exactly. A perfect fit prevents leaks and wear.

- Use clamps with a screw-tightening mechanism for adjustable, reliable grip.

- Check hoses for a high resistance to oil and chemical damage. Diesel engines can be tough on materials.

- Consider silicone hoses for better heat dissipation compared to rubber ones.

- Inspect the quality of rubber if choosing rubber hoses — aim for EPDM rubber due to its long life under harsh conditions.

- Replace both hoses and clamps at signs of wear or during major maintenance to avoid unexpected failures.

- Regularly review hose connections, especially after driving in rough conditions or changes in weather, as this can affect their performance.

Using top-notch hoses and clamps helps protect your diesel engine from overheating and other cooling system issues, keeping it running smoothly for longer periods of time.

Ensuring Proper Installation

Ensuring the coolant hoses in your diesel truck are properly installed is crucial for engine protection and performance. This guide covers key steps for securing hose connections and avoiding common pitfalls during installation.

- Select high-quality hoses and clamps that match your truck’s requirements. Look for materials designed for diesel engines to withstand extreme temperatures and pressures.

- Cut hoses to the correct length, ensuring a snug fit without excessive bending or stretching. This prevents kinks that restrict coolant flow.

- Clean all connecting points on the radiator, thermostat, and engine block before installation. Dirt or debris can cause leaks.

- Apply a thin layer of lubricant on the hose ends and fitting surfaces if recommended by the manufacturer. This eases installation and helps create a tight seal.

- Slide clamps onto hoses before attaching them to fittings. Position clamps about 1/4 inch from the hose end after it’s on the fitting for a secure grip.

- Push hoses onto fittings until they reach the marked depth line or stop point to ensure full engagement with all connection points.

- Tighten clamps firmly but avoid over-tightening, which can damage hoses or fittings. Use a torque wrench if specific clamp pressure is recommended.

- Double-check all connections after tightening to make sure there are no gaps or misalignments that could lead to leaks.

- Fill the cooling system with coolant specified for diesel engines, checking for compatibility with your truck’s specifications.

- Start your truck and let it run for several minutes, then inspect all installed hoses for any signs of leaking or bulging under pressure.

- Regularly monitor coolant levels and hose condition after installation to catch any potential issues early.

- Keep an eye out for changes in engine temperature or performance that might indicate a problem with the cooling system.

Following these steps helps maintain optimal engine temperatures, prevents overheating issues, and extends the lifespan of your diesel truck’s cooling system components.

Conclusion

Handling coolant hose problems needs expert advice. Let’s meet John Miller, a master mechanic with 20 years of experience in diesel engines and cooling systems. He holds degrees in mechanical engineering and has made significant contributions to auto repair techniques.

John says proper care of your cooling system is key. The right hoses and clamps prevent leaks and bursts. Checking for cracks and making sure coolant flows well stops overheating.

Safety matters too. Use parts that meet industry standards. Be honest about what your vehicle needs.

John suggests regular checks on hoses and connections for everyday driving or work contexts. Quality parts pay off in the long run.

He weighs the pros and cons: good maintenance avoids big repairs but costs time and money upfront. Still, it beats dealing with a broken truck.

In his final word, John finds careful attention to coolant hoses critical for diesel truck owners wanting reliability and performance from their vehicles.

FAQs

What are the steps to troubleshoot coolant hose leaks?

To handle coolant hose problems, begin by examining your cooling system for any visible signs of leakage. Check the radiator-hose and other pipes connected to it. If you find a leak, refer to a coolant hose repair guide for detailed instructions on how to fix it.

How can I prevent coolant hose failure in my car?

Regular maintenance is crucial in preventing coolant hose failure in cars including electric vehicles and hybrids. Inspect hoses regularly for wear and tear, ensure proper tire balancing, and keep air filters clean as part of diesel engine care.

Can custom coolant setups help with cooling system issues?

Yes, custom coolant setups can be beneficial especially when dealing with unique or complex vehicle models like electric vehicles or hybrids. It allows more flexibility in managing potential issues within the cooling systems.

Common mistakes made while repairing a Coolant Hose?

While repairing a Coolant Hose one should avoid using wrong tools which could damage the throttle body or not properly fitting the new parts which might lead to further leaks.

What are some recommended brands for replacing damaged hoses?

Bfgoodrich is known for its quality automotive products including tires and hoses making them an ideal choice when considering replacement options.