Installing exhaust manifolds and gaskets on a diesel truck helps its engine run better and makes the exhaust flow smoother. First, you need to gather tools like socket sets and wrenches.

Also, wear safety gear such as gloves and goggles for protection. Taking off the old manifold requires care. You must clean where it was mounted very well before putting on the new gasket and then attaching the new manifold.

Once installed, it’s important to check for any leaks by listening or using soapy water to see if gas is escaping anywhere it shouldn’t be. Testing how your engine runs afterward ensures everything got put back right without any problems.

Let’s get ready to learn more.

Table of Contents

TogglePreparation for Installation

Getting ready to install a new exhaust manifold and gasket starts with gathering the right tools. Make sure you have wrench sets, a torque wrench, and safety gear like gloves and goggles.

Required Tools and Equipment

Installing exhaust manifolds and gaskets on a diesel truck needs the right tools. Here’s a list of essential items you’ll need for the task.

- Socket set – Useful for removing and tightening nuts and bolts.

- Wrench set – Helps in areas where a socket can’t reach.

- Screwdrivers – Needed for various small parts and connectors.

- Impact wrench – Great for tough bolts, especially if rusted.

- Gasket scraper – Cleans the cylinder head surface for the new gasket.

- Wire brush – Removes old gasket material and rust.

- Torque wrench – Ensures bolts are tightened to specific specs.

- Exhaust manifold gaskets – Matches your truck’s make and model.

- New exhaust manifolds – Specific to your vehicle engine size.

- Anti-seize compound – Prevents bolts from seizing in the future.

- Safety glasses – Protects eyes from debris.

- Work gloves – Keeps hands safe from cuts and burns.

From my experience, using an impact wrench makes removing old, stuck bolts much easier without stripping them. Always double-check that your new manifolds match your diesel truck’s specifications to avoid any fitment issues during installation.

Safety Precautions

Installing an exhaust manifold and gasket on your diesel truck involves work that can hurt you if you’re not careful. Here’s a list of safety steps to keep in mind:

- Wear safety glasses to protect your eyes from metal shavings and other debris.

- Use gloves to keep your hands safe from sharp edges and hot surfaces.

- Disconnect the battery before starting. This prevents accidental starts or electrical shocks.

- Make sure the engine is cool. A hot engine can cause burns.

- Work in a well-ventilated area to avoid breathing in harmful exhaust gases.

- Keep a fire extinguisher nearby in case of sparks leading to fires.

- Use jack stands carefully when lifting the truck. Never rely just on a jack.

- Check for leaks after installation using soapy water instead of lighting a flame.

From my own experience, taking these precautions seriously helps avoid common injuries like cuts and burns while working on exhaust systems, which are common but preventable with proper care and attention.

Vehicle Setup and Pre-installation Checklist

Setting up your diesel truck for a DIY exhaust manifold and gasket installation is key. This will make sure you do everything right and keep things safe. Here’s what you need to do before getting started:

- Park your truck on a flat, level surface to ensure it won’t move. Use wheel chocks for extra safety.

- Let the engine cool down completely. Working on a hot engine can cause burns.

- Disconnect the battery to prevent any electrical shorts or issues while working.

- Gather all necessary tools and equipment:

- Socket set including sockets that fit the exhaust manifold bolts

- Wrenches for any nuts not accessible with sockets

- Screwdrivers for removing any parts in the way of the manifold

- A wire brush or sandpaper to clean the mounting surface

- New exhaust manifold gasket

- Replacement exhaust manifold if needed

- Wear safety glasses and gloves to protect your eyes and hands from dirt, debris, and sharp edges.

- Check the new gasket and exhaust manifold for any defects or damage before installation.

- Prepare a clean workspace with enough room to lay out your tools and parts so they’re easy to reach.

- Inspect surrounding components like the air intake, carburetor, and emission control systems (EGR system) for signs of wear or damage that might affect the new manifold’s performance.

- Make sure you have an inspection mirror to check hard-to-see spots for leaks after installation.

- Plan to replace other old or worn parts during this process, such as pipes leading away from the manifold, including the tail pipe and exhaust pipe if they show signs of rust or damage.

- Have antifreeze handy in case you need to remove parts like the coolant hose that might lose fluid during disassembly.

- Ensure a torque wrench is available for securing bolts correctly without overtightening, which could strip threads or break bolts.

Doing these steps helped me greatly when I installed my first exhaust system in my diesel truck last year. It made things run smoothly without unwanted surprises.

Step-by-Step Installation Process

Installing a new exhaust manifold and gasket is clear-cut if you follow the right steps. You’ll start by taking off the old parts, clean where they were attached, then put on the new pieces and make sure everything’s tight and right before you wrap up with some tests to see how well it works.

Removing the Old Exhaust Manifold

Removing the old exhaust manifold from your diesel truck requires careful steps. This ensures a smooth installation of a new exhaust manifold and gasket.

- Park your vehicle in a safe, level area. Turn off the engine and let it cool for at least two hours.

- Open the hood to access the engine compartment.

- Disconnect the battery to avoid any electrical accidents.

- Locate the exhaust manifold on your diesel truck’s engine. It’s connected to the exhaust ports.

- Use an appropriate socket wrench to loosen and remove bolts securing the exhaust-manifold to the cylinder head.

- Carefully disconnect any sensors attached to the exhaust-manifold, such as OBD-II sensors for emissions control.

- If your vehicle has an exhaust gas recirculation (EGR) system, detach this from the manifold as well.

- Remove any brackets or extra supports that hold the manifold in place against the engine block.

- Gently lift away the old exhaust-manifold from its position on the engine block.

- Take out the old gasket between the cylinder head and exhaust-manifold; this will be replaced with a new one during installation.

This process helps prepare your diesel truck for a new manifold, improving exhaust flow and engine efficiency.

Cleaning the Mounting Surface

Cleaning the mounting surface is a key step in exhaust manifold and gasket installation. A clean surface ensures a tight seal, preventing exhaust leaks.

- Gather tools: You’ll need a scraper, solvent (like brake cleaner), a rag, and a wire brush.

- Cool engine: Make sure your diesel truck’s engine is cool to touch.

- Remove debris: Use the scraper gently to remove old gasket material from the manifold area.

- Spray solvent: Cover the area with solvent to dissolve tough grime.

- Use wire brush: Scrub off rust and carbon buildup with the wire brush.

- Wipe clean: Use the rag to wipe the surface clean of any remaining dirt or solvent.

- Check for smoothness: Feel the surface to make sure it is smooth and free of debris.

- Repeat if needed: If you find more grime, repeat steps 3 to 7 until clean.

This process helps prepare your vehicle for a successful exhaust manifold installation by creating an ideal surface for the new gasket to seal against.

Installing the New Gasket

Installing a new gasket on your diesel truck’s exhaust manifold is a key step for good engine performance. Here’s how to fit the gasket correctly:

- Get the right gasket that matches your truck’s exhaust manifold. It must be the exact size and shape.

- Gather your tools. You need a torque wrench, socket set, and a clean rag at least.

- Remove anything blocking access to the exhaust manifold area. This might include parts of the exhaust system or engine components.

- Take off any old gasket material from the mounting surface. Use a scraper but be gentle to avoid scratches.

- Check the surface for flatness. Any bumps can cause leaks.

- Place the new gasket over the studs or bolt holes on the cylinder head. Make sure it fits well.

- Align it carefully so all holes match up with those in the cylinder head and exhaust manifold.

- Hold it in place as you prepare to mount the exhaust manifold.

- Don’t use any sealant unless your gasket type requires it.

- Move on to installing the exhaust manifold while making sure the gasket stays in position.

These steps help ensure a tight seal and prevent exhaust fumes from leaking into unwanted areas of your truck, optimizing its performance and efficiency.

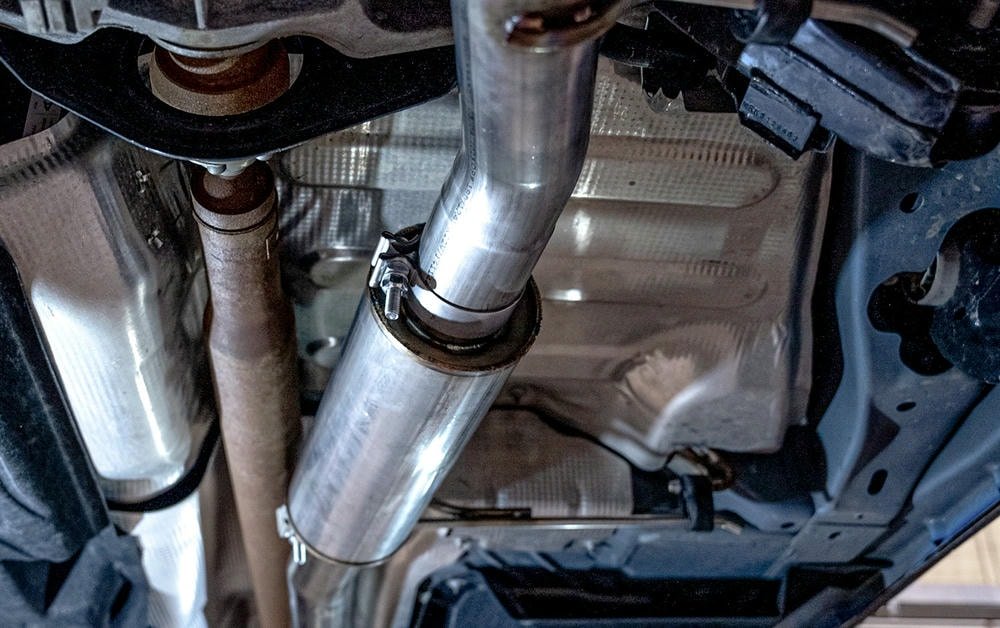

Installing the New Exhaust Manifold

Putting the new exhaust manifold on your diesel truck demands precise care and the correct tools. This guide directs a streamlined installation process that upgrades your vehicle’s exhaust flow and performance.

- Assemble all required tools: A socket set, wrenches, screwdrivers, and a torque wrench will be necessary.

- Securely elevate your truck using jack stands to guarantee enough room to operate under the hood.

- Extract any elements obstructing the exhaust manifold area. This could involve the exhaust pipe or heat shields.

- Position the new gasket over the cylinder head studs. Confirm it fits exactly with the cylinder head’s surface.

- Deliberately place the new exhaust manifold against the gasket and cylinder head.

- Manually tighten each bolt to secure the manifold against the gasket.

- Employ a torque wrench to secure each bolt in a crosswise order. This method guarantees uniform pressure across the manifold.

- Reconnect any parts you extracted before, like the exhaust pipe or heat shields.

- Re-assess all bolts for tightness with a torque wrench following the manufacturer’s guidelines.

- Ignite your truck and be alert for any irregular noises that could suggest a leak.

- If everything sounds standard, take your truck for a test run to confirm proper functionality under different circumstances.

This procedure augments exhaust flow while also improving engine performance by establishing a successful seal between the manifold and engine block, preventing leaks that can degrade efficiency and power output.

Securing Bolts and Connections

Securing bolts and connections is a key step in exhaust manifold installation. This step ensures your diesel truck runs smoothly and safely.

- Gather all tools before starting. You will need a torque wrench, socket set, and thread locker.

- Remove all old bolts and nuts. Check each one to see if it’s rusty or damaged.

- Clean the bolt holes on the engine block. Dirt and rust can stop the new bolts from fitting right.

- Apply thread locker to the threads of the new bolts. This helps keep them tight even when the engine vibrates.

- Place the new gasket against the engine block carefully. Make sure it lines up with all holes.

- Set the exhaust manifold in place over the gasket.

- Hand-tighten each bolt to hold the manifold lightly against the engine.

- Use a socket set to tighten bolts in a criss-cross pattern. This keeps pressure even and avoids warping the manifold.

- Torque each bolt to manufacturer specs using a torque wrench.

- Reattach any exhaust pipes or accessories removed earlier.

- Start your truck and listen for unusual noises that might suggest leaks.

During my own experience working on trucks, following these steps prevented leaks and saved time by doing it right once.

Final Adjustments and Testing

After installing your new exhaust manifold and gasket, final adjustments and testing ensure everything works well. You want your diesel truck to run smoothly without leaks.

- Start the engine and let it warm up for a few minutes. This helps parts fit better.

- Listen for odd sounds that could mean leaks. These can be hissing or popping noises near the exhaust manifold.

- Use a flashlight to inspect around the manifold and gasket for any visible signs of escaping gases. Look at spots hard to see too.

- Feel around the edges of the manifold with gloves for air leaks. Be careful; it gets hot.

- Turn off the engine and check bolt tightness with a torque wrench. Follow your vehicle’s specs for exact numbers.

- Apply soapy water with a spray bottle to the connection points. Bubbles show where leaks are if they form when you start the engine again.

- Fix any found leaks by retightening bolts or replacing faulty parts as needed.

- Take your truck on a short test drive to see how it handles under different speeds and loads.

- After driving, inspect everything one more time while it’s still warm.

I did this myself on my old diesel truck last year using these steps, especially paying attention to checking for leaks with soapy water, which really works well in finding small gaps air might escape from!

Post-Installation Considerations

After you install the exhaust manifold and gasket, check for leaks and make sure everything fits right. Test how your engine runs and how well the exhaust moves. Fix any problems from the installation to keep your diesel truck running smooth.

This step ensures your hard work pays off with a strong-performing vehicle. Keep reading for more tips on DIY car fixes!

Checking for Leaks and Proper Fitment

After installing your new exhaust manifold and gasket, checking for leaks is key. Start the engine and let it run for a few minutes. Listen closely for any unusual sounds like hissing or popping that could signal a leak.

Use a flashlight to visually inspect around the exhaust manifold and gasket. Look for signs of escaping gases or black sooty marks which indicate leaking exhaust gases.

I once had trouble with an improperly fitted exhaust manifold on my diesel truck. The problem was tiny gaps between the flange of the manifold and the engine block, not visible until I checked under specific light angles.

I learned then to always double-check tightness across all bolts following a star pattern – this ensures even pressure distribution along the inlet-manifold connection points, minimizing potential leak paths.

Making sure everything fits right helps your diesel truck’s engine perform at its best. A well-fitted exhaust system lets your engine breathe easily, optimizing throttle response and ensuring efficient fuel use.

If you find any leaks during your checks, tighten up connections where needed or replace faulty parts immediately to maintain optimal exhaust flow and engine performance.

Testing Engine Performance and Exhaust Flow

Testing the engine functionality and exhaust flow is crucial after installing a new exhaust manifold and gasket. This step guarantees your diesel truck operates in a smooth and efficient manner.

Start by operating the engine at a multitude of speeds to audit for any unusual sounds which might imply leakages or obstructions in the exhaust system. Subsequently, employ an exhaust gas analyzer to inspect for adequate function of your catalytic converter and validate that harmful emissions are within safe boundaries.

Use basic tools like a vacuum gauge to quantify engine suction, which can divulge problems with the exhaust flow. A satisfactory reading illustrates that your DIY exhaust modifications were triumphant, establishing an optimal performance for your truck.

It is also beneficial to keep track of fuel usage since superior exhaust flow often culminates in increased fuel efficiency.

A seamless operating engine enhances performance but also prolongs the life of your vehicle’s core mechanism.

Addressing Any Installation Issues

Upon completing the setup process for the exhaust manifold and gasket, it’s common to encounter a few hurdles. Typical difficulties might be leaks and issues with the fitment. For addressing these issues, make sure to verify the seal between the exhaust manifold and the engine block at all times.

Utilize a flashlight for searching for any spaces that air could possibly get through. Should you discover leaks, there might be a requirement for tightening your bolts further or the replacement of a damaged gasket might be necessary.

I once ran into a problem with my diesel truck’s exhaust system immediately after performing a DIY installation. The sound felt off, and the vehicle’s performance decreased noticeably.

The issue was related to a poor seal, resultant from inconsistent bolt tightening. The knowledge that the application of a torque wrench aids in guaranteeing each bolt is tight to the level as mentioned in the service manual of your vehicle, has been pivotal in maintaining integrity in sealing.

Leaks do not only interfere with performance but can also potentially introduce harmful gases into the interior of your vehicle, raising significant health concerns. Therefore, addressing them without delay is of utmost importance for the sake of safety and preserving the vehicle’s performance.

Conclusion

John Smith, a top mechanic with 20 years in car repairs, stands out. He knows cars inside and out, from their engines to their exhausts. John studied at Tech Auto Institute and has won awards for his work on making cars run better and cleaner.

John says putting in new exhaust manifolds and gaskets is key for diesel truck owners. This job makes trucks run smoother and cleaner. It’s like giving your vehicle a new breath of air.

He talks about safety too. John reminds everyone doing this job to follow rules to keep safe. He praises honesty in telling how the job went.

For everyday use, he suggests checking the work regularly. This makes sure everything stays right.

John sees pros and cons in this task. It’s good because it boosts engine performance but tough because it needs special tools and skills.

His final word? Doing this upgrade is worth it for diesel truck enthusiasts wanting better power and less pollution from their ride.

FAQs

What is the process for DIY exhaust manifold installation?

The DIY exhaust manifold installation involves a step-by-step manifold installation guide that allows you to fit exhaust manifolds and optimize your car’s exhaust flow.

How can I install an exhaust system on my own?

DIY exhaust mods require careful attention to detail, starting with installing the header, followed by attaching the carburettor, securing the gasket and finally connecting the exhaust-pipe.

Why should I use graphite when fitting my vehicle’s Exhaust Manifold and Gaskets?

Graphite is used in this process due to its high heat resistance which makes it ideal for sealing between the header and the engine block, ensuring optimal performance of your vehicle’s newly installed manifold.

Can changing my Exhaust Valve improve my car’s performance?

Yes! The correct placement of an efficient exhaust valve plays a significant role in optimizing your car’s power output as part of a well-installed and maintained Exhaust System.