A downpipe back exhaust system is a key part of a diesel truck, helping it run smoothly and with power. This article explains how to take care of your exhaust system and fix common problems.

Keeping your exhaust in good shape involves checking for leaks, cleaning it well, and making sure parts fit tight. Trucks often face issues like holes in the exhaust, rust eating away at the metal, loose parts shaking free, and troubles with the catalytic converter – a part that cleans harmful gases.

Fixing these problems early means your truck works better for longer. Using strong materials and putting everything together right also helps avoid troubles later on. Get ready to learn how to keep your truck’s exhaust working great!

Table of Contents

ToggleMaintenance Tips for Downpipe Back Exhaust Systems

Keeping a downpipe back exhaust system in top shape requires regular check-ups and upkeep. This involves inspecting for leaks or rust, cleaning, and ensuring all parts are tightly connected.

Regular Inspection for Leaks and Corrosion

Diesel truck owners need to maintain their downpipe back exhaust systems to ensure peak performance. Regular checks help find leaks and corrosion early.

- Look at the entire exhaust system every month. This includes the tailpipe, exhaust manifold, and catalytic converter. Seeing problems early can save money.

- Use a flashlight and mirror for hard-to-see spots. Bright light helps spot tiny holes or rust signs on the exhaust pipes.

- Listen for strange noises while driving. Rumbles or hissing can signal leaks in the system.

- Check for water drops or soot at the connection points, like where pipes meet the muffler. These signs often mean there’s a leak.

- Feel around joints with gloves on when the engine is cool. You might find escaping air from cracks not easily seen.

- Smell around the exhaust area when parked after a drive. A strong odor can point to gases leaking from somewhere in the system.

- Inspect hangers and mounts for wear or damage. They hold your system in place, but can fail over time.

- Look closely at welds along pipes and near flanges for tiny cracks or rust spots that could grow bigger.

Using this list helps diesel truck owners catch exhaust issues before they turn into bigger problems, keeping trucks running well and safely on the road.

Cleaning and Polishing the Exhaust System

Cleaning and polishing the exhaust system of a diesel truck aids in maintaining its aesthetic appeal and functionality. Owners can utilize a soft cloth and cleaners designed for stainless steel to eradicate dirt, grease, and exhaust gases from the exterior of their systems.

This action is critical since clean pipes prevent corrosion induced by detrimental chemicals adhering to the metal. Post cleaning, applying polish intended for stainless steel will enhance the surface’s luster and provide an additional defense against rust.

To ensure comprehensive cleaning, owners may require a screwdriver or washer to disassemble any components obstructing access to the exhaust system. Concurrently, they should inspect gaskets close to the tailpipe.

Such steps enhance the visual appeal of the exhaust and facilitate early identification of rust or leakages, which could progress into greater issues if neglected.

Checking and Tightening Connections

Maintaining downpipe back exhaust systems in diesel trucks involves keeping connections tight. Loose parts can lead to leaks and performance issues.

- Start with a visual inspection. Look for signs of wear or damage where parts connect.

- Use a wrench to check bolts and clamps along the exhaust system. They should not move easily by hand.

- Pay special attention to the areas near the turbocharger and catalytic converters. These spots get very hot and can loosen over time.

- Listen for unusual noises that might suggest a loose connection, like rattling or hissing sounds under the truck.

- Check the on-board diagnostics (OBD-II) for error codes that could signal an exhaust issue needing attention.

- After driving, once the truck has cooled down, recheck connections. Heat can cause metal to expand and reveal loose spots you missed.

- If you find rusted bolts or clamps, replace them with stainless-steel ones for better durability against corrosion.

- Make sure tail pipe connections are secure, as these are often bumped or moved during off-road driving.

- For custom exhaust systems, consult the installation guide to ensure all unique parts are tightened to specifications.

- Annually bring your truck to a professional for an exhaust system inspection, even if no problems are obvious.

Following these steps helps prevent exhaust leaks and maintains fuel efficiency in diesel trucks by ensuring everything stays tight and right where it belongs.

Monitoring for Unusual Noises or Performance Issues

Monitoring for unusual noises or performance issues is key in keeping a diesel truck’s downpipe back exhaust system in top shape. Listening and feeling how your truck runs can help catch problems early.

- Listen for hissing or popping sounds from the exhaust. These noises might mean there are exhaust leaks.

- Pay attention if your truck starts making louder rumbling sounds. This could indicate muffler problems.

- Notice any changes in engine performance, like a drop in power or fuel efficiency. This might show there’s a blockage in the system.

- Keep an ear out for rattling under the car. Loose or damaged components often cause these sounds.

- Watch your dashboard for the check engine light. It turns on for many issues, including those with the catalytic converter.

- Feel if your truck vibrates more than usual while driving, especially at specific speeds or when accelerating. Vibrations can point to exhaust system parts that have come loose or are wearing out.

- Smell for strong odors inside the cabin, suggesting an exhaust leak letting dangerous gases into your vehicle.

Use this guide to detect signs early and prevent bigger problems with your downpipe back exhaust system.

Common Issues with Downpipe Back Exhaust Systems

Downpipe back exhaust systems in diesel trucks often face problems like leaks, rust, and parts coming loose. These issues can hurt the truck’s performance and sound. Read on to find out how to spot and fix these common troubles.

Exhaust Leaks

Exhaust leaks in diesel trucks can lower performance and raise safety risks. These leaks often start at weak spots like welds or where parts join together. Fixing exhaust leaks early keeps the truck running well and prevents harm from fumes.

To find a leak, listen for a loud hissing or whistling noise while the engine runs. Inspect the downpipe back exhaust system, focusing on areas close to clamps and joints. Use a flashlight during this check for better visibility.

To fix leaks, one might need welding tools or new gaskets to seal gaps securely. Always wear safety gear like gloves and eye protection when working on exhaust repairs to avoid burns or other injuries.

Rust and Corrosion

Rust and corrosion are common enemies of downpipe back exhaust systems in diesel trucks. These issues often start when moisture gets trapped inside or on the surface of the exhaust components.

Over time, this leads to metal fatigue and weakened parts. Owners might see rusted areas or spots where pieces have corroded through, causing leaks and other performance problems.

One truck owner noticed his vehicle’s performance dropping over several months. Upon inspection, he found severe corrosion near the muffler and catalytic converter. This was due to road salt accumulating over winter, a harsh reality for many living in colder climates.

To tackle these challenges, regular checks for signs of rust and applying anti-corrosion sprays help extend the life of an exhaust system. Also, replacing corroded sections with high-quality materials prevents future issues, ensuring that emissions regulations are met without sacrificing performance.

Loose or Damaged Components

Parts of your downpipe back exhaust system can become loose or damaged over time. This happens from normal use or rough driving conditions. For diesel truck owners, it’s key to check these parts regularly.

Look for anything that seems out of place or sounds strange during operation.

Early detection and repair save both time and money.

You might spot issues with clamps, hangers, or the exhaust pipes themselves. Using a wrench and screwdriver, you can tighten most connections yourself. If you find something broken, replacing it as soon as possible is best to avoid larger problems later on.

From my own experience working on diesel trucks, catching these little issues early makes a big difference in how well the exhaust system works long term.

Catalytic Converter Issues

Catalytic converter problems can hurt a diesel truck’s performance. These parts change harmful gases into less dangerous emissions. If they fail, it might be due to clogging or damage.

A clogged catalytic converter makes exhaust flow hard, leading to loss of power and fuel efficiency. Damage can happen from rough roads or poor upkeep.

Owners should check for trouble signs like increased emissions or a drop in engine power. Use diagnostic tools like OBD2 scanners to find issues early. Fixing these problems often means replacing the damaged part.

For best results, choose high-quality replacements that meet environmental rules.

How to Address and Prevent Common Issues

To fix and stop problems with downpipe back exhaust systems, it’s crucial to catch them early. Use strong parts and make sure they are put in right.

Early Detection and Repair

Early detection and repair of downpipe back exhaust problems are key to keeping diesel trucks running smoothly. These steps can help prevent bigger issues and costly repairs.

- Listen for exhaust leaks. These often sound like a hiss or whistle coming from the exhaust system. Catching these early means simpler fixes.

- Watch for signs of rust and corrosion on the exhaust components. This damage happens over time but speeds up with exposure to salt and moisture.

- Check for loose or damaged parts during oil changes or other routine maintenance. Vibrations from driving can loosen connections.

- Use a diagnostic tool to check for trouble codes related to the exhaust system, turbocharger, or oxygen sensor. These codes can point to specific issues needing attention.

- Inspect the catalytic converter regularly for signs of blockage or damage, as failures here can lead to reduced performance and fuel efficiency.

- Install high-quality materials and parts when replacements are necessary. Better parts last longer and perform better.

- Ensure clamps, bolts, and hangers are tight and in good condition to avoid parts becoming loose while driving.

- Keep an eye on fuel efficiency rates; drops might signal an exhaust problem affecting engine performance.

- Check mufflers for holes or internal damage, as they play a critical role in controlling noise and emissions from the vehicle.

- Schedule regular inspections with a professional who has experience with diesel trucks and custom exhaust systems.

Taking these steps helps catch problems early, making repairs simpler and keeping trucks running well.

Using High-Quality Materials and Parts

Choosing high-quality materials and parts for a downpipe back exhaust system is crucial. This choice helps avoid common problems like rust and leaks. Diesel truck owners know that good materials last longer.

For example, using stainless steel in the exhaust system fights off rust better than other metals. High-grade gaskets ensure tight seals to prevent leaks.

Diesel truck owners have seen how quality pays off firsthand. They pick parts like turbochargers carefully, knowing these components affect performance and durability. Quality welding methods such as TIG ensure strong connections that withstand heat and pressure well.

Investing in top-notch materials means fewer repairs and better performance over time for diesel trucks.

Ensuring Proper Installation

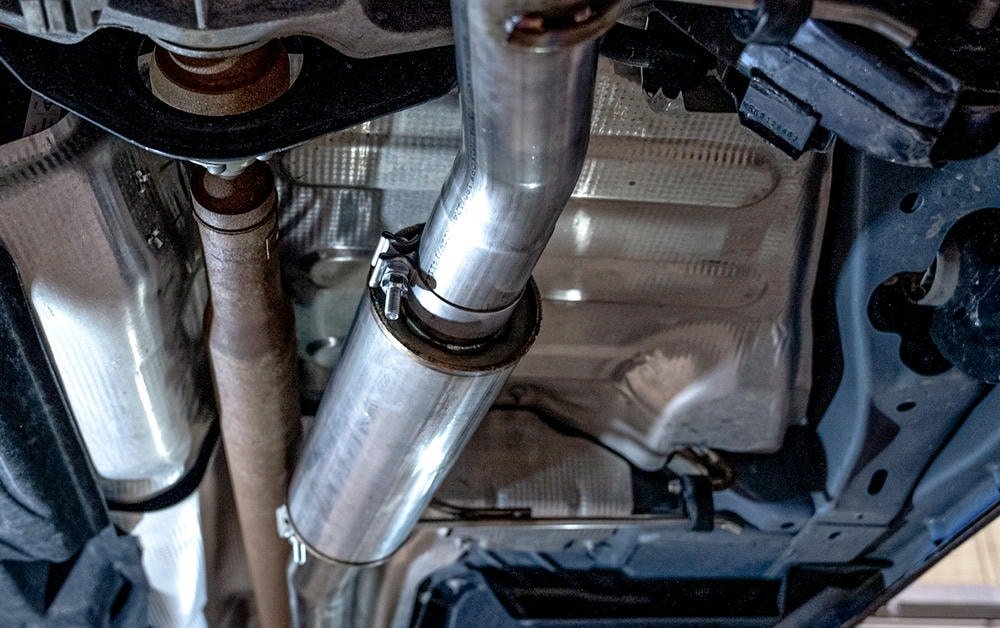

Proper installation is key for a downpipe back exhaust system to work well. This means making sure every part fits right and connects tightly. Workers use tools like welders to join parts of the exhaust system securely.

They also check that the system matches the diesel truck’s model and year. A good fit stops leaks and other problems.

Proper installation keeps your truck running smoothly.

For best results, experts must handle the install. They know how each piece should line up. Their skills with tools like TIG welding ensure strong connections that last long. They also make sure to follow environmental regulations while working on your vehicle’s exhaust system, keeping it eco-friendly.

Conclusion

Experts like John Miller, with years of experience in auto care, shine light on downpipe back exhaust systems. John has a degree in mechanical engineering and decades of work with diesel trucks.

He knows how important these systems are for vehicle performance.

John says the right maintenance stops leaks and rust. This keeps trucks running better for longer. He points out that using good materials makes repairs last.

For safety, John talks about meeting standards and being open about exhaust system work. This helps everyone know their truck is safe to use.

He suggests drivers check their exhaust often to catch problems early. Simple steps can prevent big issues.

John weighs the pros and cons too. While these systems improve power, they might need more upkeep than basic exhausts. Drivers should think about this when choosing upgrades.

Lastly, John believes well-maintained downpipe back exhaust systems are worth it for diesel truck owners looking for more from their vehicle.

FAQs

What are some common downpipe back exhaust problems?

Common issues with downpipe back exhaust systems can include leaks, performance issues related to diesel or gasoline combustion engines, and diagnostic trouble codes appearing on hybrid and electric vehicles.

How can I maintain my downpipe back exhaust system?

Maintaining your downpipe back exhaust system involves regular system upkeep such as checking for leaks, ensuring the components are well cared for, and conducting turbocharger maintenance if applicable.

Can you give me a guide on troubleshooting downpipe back exhaust issues?

Troubleshooting your downpipe’s problems typically starts by identifying the root cause of any noticeable drop in fuel efficiency or unusual noises from your automobile’s tail end. This could be due to an issue with the welded parts or other components of the system.

How do I fix common problems with my downpipe back exhaust system?

Fixing common problems usually involves repairing leaks in the exhaust component care routine or addressing any identified diagnostic trouble codes that may indicate more complex issues within alternative propulsion systems like those found in hybrids or electric vehicles.

Are there specific maintenance considerations for custom-made downpipes?

Yes! Custom-made or performance-enhanced models might require more frequent check-ups due to their unique design and potential innovations included for sustainability purposes which could alter traditional maintenance routines.