Maintaining a diesel truck requires attention, particularly pertaining to the turbo back exhaust system. This component of your truck assists with performance and manages emissions.

It’s crucial to maintain it. Regular inspections for leaks, rust, and damage can prevent expensive repairs in the future. Moreover, employing quality parts and being alert for unusual noises from your truck are intelligent measures.

Clean and secure parts of the system to retain its aesthetics and function correctly. Annually, have a professional inspect it as well. This practice enables the early detection of issues.

It’s time to learn how to maintain your truck at its best!

Table of Contents

ToggleMaintenance Tips for Turbo Back Exhaust Systems

Keeping your turbo back exhaust system in top shape is key. This means regular checks for holes and rust, cleaning the parts, making sure everything is tight, and watching out for odd sounds or how it runs.

Regular Inspection for Leaks and Corrosion

Regular inspection for leaks and corrosion in turbo back exhaust systems is key to maintaining performance and durability. Diesel truck owners need to pay close attention to their vehicle’s exhaust system to prevent common issues.

- Look closely at the exhaust pipes and tail pipe for any signs of rust or holes. These can lead to exhaust leaks.

- Check all welds on the exhaust system. Use a flashlight to see better. Welds should be intact with no cracks.

- Inspect gaskets between exhaust components. They should not show signs of wear or damage.

- Touch the connections lightly with gloves to feel for loose parts or fittings that might need tightening.

- Use an inspection mirror to check hard-to-see areas under the vehicle for corrosion, especially if you drive on salty roads.

- Listen for unusual noises like hissing or tapping which could mean a leak or loose component.

- Smell around the exhaust while the truck is running (but do not inhale directly). A strong smell may indicate an exhaust leak.

- Use a damp cloth to clean surfaces and look for fresh rust or discoloration that indicates corrosion starting.

- Check the catalytic converter and diesel particulate filter (DPF) for any visible damage or unusual signs since they are crucial for reducing emissions.

10.Engine light on your dashboard can hint at issues in the exhaust system too, so get it checked by professionals if it lights up.

Regular checks help catch problems early, saving time and money in repairs and ensuring your diesel truck runs smoothly and efficiently

Cleaning and Polishing the Exhaust System

Cleaning and polishing the exhaust system of a diesel truck helps keep it looking good and working well. First, use a soft cloth and mild cleaner to wipe away dirt and grime from the stainless steel parts.

This prevents rust and keeps the metal shiny. For tough spots, a special polish designed for exhaust systems can make them look new again.

After cleaning, check all parts like flanges and welds for signs of wear or damage. If you find any issues, fixing them early can save time and money later. This care helps your turbo back exhaust perform at its best, improving fuel consumption and reducing the risk of engine knocking.

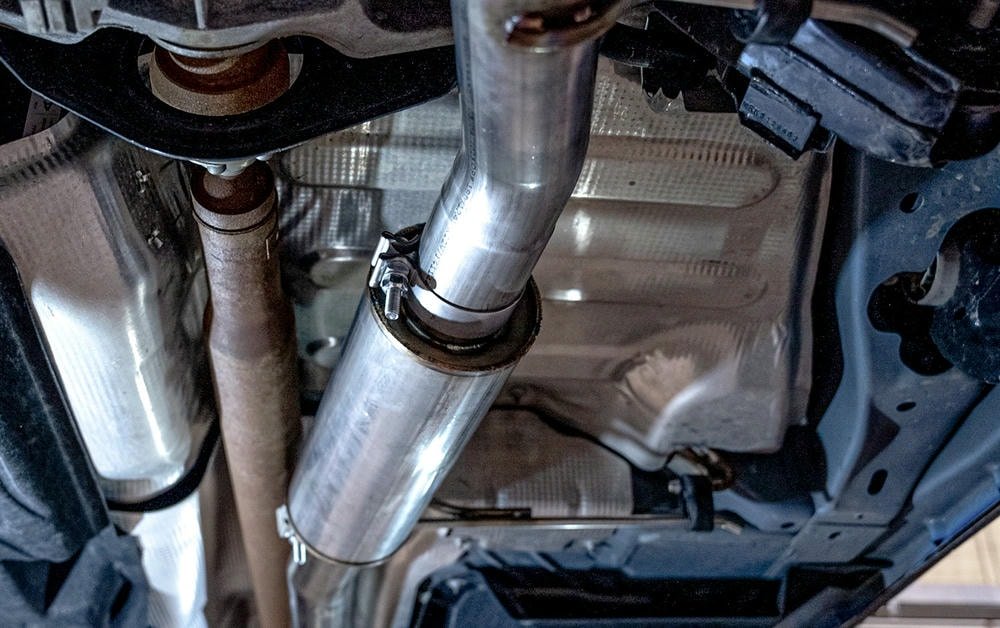

Checking and Tightening Connections

Maintaining turbo back exhaust systems in diesel trucks is key for performance. Connections in these systems must be tight and secure to avoid leaks and other problems. Here’s how to check and tighten these connections:

- Locate all clamps and bolts on the exhaust system. These are usually found where different parts of the system join together.

- Use a wrench or socket set to gently tighten each connection. Do not over-tighten as this can strip the threads or break the hardware.

- Inspect rubber mounts or hangers that support the exhaust system. Replace any that are worn out or damaged.

- Check the turbocharger clamp specifically, as it’s crucial for keeping the turbocharger securely attached to the exhaust system.

- Look at welded joints for signs of cracking or weakness. A professional welder may need to fix any issues found here.

- Listen for unusual noises after tightening connections, such as rattling, which could indicate a loose part.

- Use a torque wrench for precise tightening, especially important on critical components like oxygen sensors and catalytic converter attachments.

- If equipped with an anti-lag system, ensure connections are extra secure due to increased stress on exhaust components.

- Apply anti-seize compound on bolts during reassembly to prevent corrosion and make future removal easier.

- Regularly check connections after long drives or heavy use, as vibration can loosen them over time.

- Monitor the check engine light and use onboard diagnostics (OBD) tools to identify issues related to loose exhaust components quickly.

- Ensure all gaskets between sections of the exhaust system are intact; replace them if they show signs of wear or damage.

By following these steps, diesel truck owners can keep their turbo back exhaust systems functioning efficiently, preventing common issues like leaks and ensuring optimal vehicle performance.

Monitoring for Unusual Noises or Performance Issues

Listening for strange noises or drops in performance is key to keeping a diesel truck running well. These signs often mean there’s a problem with the turbo back exhaust system. Owners might hear hisses, rattles, or whistles coming from the exhaust.

These noises can point to leaks, loose parts, or other issues.

Using tools like on-board diagnostics helps find the root cause of these problems. For instance, a sudden drop in boost could mean there’s an air leak in the system. Diesel truck owners should check their vehicle regularly and use diagnostics to spot performance issues early.

This way, they can fix small problems before they turn into big ones.

Common Issues with Turbo Back Exhaust Systems

Turbo back exhaust systems in diesel trucks often face problems like leaks, rust, and damaged parts. These issues can hurt the truck’s performance and sound. To learn how to keep your system in top shape, keep reading.

Exhaust Leaks

Exhaust leaks are a common issue in turbo back exhaust systems of diesel trucks. These leaks happen when gases escape from the system before they reach the end of the exhaust. This can harm your truck’s performance and increase fuel usage.

Causes include holes or cracks in the exhaust pipes, loose connections, or damaged seals.

Fixing an exhaust leak early is key to keeping your truck running well. Check for signs like louder noise coming from the exhaust or a smell of gas inside your truck. Fixing may involve welding holes, replacing seals, or tightening parts that have come loose.

Using stainless steel for repairs can prevent future rust and damage.

A small leak might not seem like a big deal, but it can lead to bigger problems down the road.

Rust and Corrosion

Rust and corrosion are big problems for turbo back exhaust systems in diesel vehicles. These issues start when metal parts get exposed to water and air over time. This mix can eat away at the metal, making holes that hurt performance and cause leaks.

Diesel truck owners should check their systems often for any signs of this damage.

To fight rust, use stainless-steel parts when you can. Stainless steel fights off rust better than other metals. Also, keep your system clean from dirt and moisture that can speed up corrosion.

Checking welds is key too, as these areas are often the first to go bad. Tools like tig welding help make stronger connections that last longer against harsh conditions. Keeping an eye on these things will help your turbo charged vehicle run smoother for longer.

Loose or Damaged Components

Parts of the exhaust system can come loose or get damaged. This happens from driving over rough roads or hitting something. It affects how your diesel truck runs and sounds. Check for these problems often, especially after a long trip or if you hear weird noises.

Welders are tools that can help fix these parts. If you find a part that’s not tight or is broken, welding might be needed to make it strong again. As someone who owns a diesel truck, fixing these issues early stops bigger problems later.

Catalytic Converter Issues

Catalytic converter issues can cause big problems for diesel truck owners. This part of the exhaust system helps reduce harmful gases from exhaust emissions. If it fails, a vehicle might not pass emissions tests or could run poorly.

Signs of trouble include less power when accelerating and a sulfur smell.

A healthy catalytic converter is key to a truck’s performance.

To fix these issues, checking for clogs or damage is vital. Sometimes, replacing the catalytic converter is necessary for severe cases. Keeping an eye on this component ensures trucks stay efficient and eco-friendly.

How to Address and Prevent Common Issues

Fixing and stopping problems with turbo back exhaust systems needs quick action and the right choices. Spot issues early and fix them using quality parts to keep the system running well.

Early Detection and Repair

Early detection and repair are key to keeping a turbo back exhaust system running smoothly. This approach helps prevent small issues from turning into big, expensive problems.

- Listen for changes in exhaust sound. This could mean there is a leak or damage.

- Check the exhaust color. Blue or black smoke can signal trouble.

- Feel for unusual vibrations. These might point to loose components.

- Watch for decreased fuel efficiency. It often indicates an issue in the system.

- Inspect the system regularly for signs of rust and corrosion.

- Look at connections to make sure they’re tight and not damaged.

- Change parts with high-quality replacements when needed.

- Use a moisture repellent to fight against rust on metal parts.

- Check the catalytic converter for blockages or damage as it’s crucial for reducing emissions.

- Have a professional inspect your system annually.

Staying ahead of trouble with these steps ensures that your truck’s turbo back exhaust maintains performance and lasts longer without costly repairs down the road.

Using High-Quality Materials and Parts

Selecting premium materials and components for turbo back exhaust systems effectively prevents many problems. Owners of diesel trucks understand that suitable parts maintain their engine’s efficiency.

This includes utilizing stainless steel components for rust resistance and high-grade gaskets to avoid leaks. Taking these measures extends an exhaust system’s life, thereby reducing the cost of repairs.

Specialists concur that investing in superior items such as turbines and anti-lag systems is beneficial. They contribute to the truck’s increased power and reliability. For instance, a mechanic noticed a more rapid failure rate in trucks with low-cost parts as compared to those fitted with durable metals and precision engineering.

This indicates that an initial investment in better quality alleviates future problems.

Quality remains ingrained long after the price is forgotten.

Ensuring Proper Installation

Proper placement of a turbo back exhaust system is essential to steer clear of common complications. Diesel truck proprietors should constantly utilize superior materials and parts.

This implies selecting the correct pipes, gaskets, and clamps that adhere to their vehicle’s specific requirements. A proficient mechanic with knowledge in turbocharged vehicles can certify everything fits correctly and functions harmoniously.

They possess the instruments to check for leaks and guarantee connections are firm.

From practical experience, it’s evident that bypassing steps during the installation process can prompt significant issues further down the road. For example, an Audi S4 owner once disregarded a step in fastening all the bolts as required.

This misstep resulted in an exhaust leak and dwindled performance until rectified accurately. Adhering to guidelines strictly averts metal fatigue, maintains turbochargers operational, and helps sidestep expensive maintenance in the future.

Conclusion

Maintaining turbo back exhaust systems is crucial for diesel truck owners. John Doe, an expert with over 20 years in automotive engineering, shares insights. He has a degree in Mechanical Engineering and has worked on numerous projects improving vehicle performance.

His work ensures trucks run smoothly and efficiently.

John notes that regular checks for leaks and corrosion keep the system working well. This helps the truck use fuel better and gives more power when you press the gas. Cleaning keeps parts from wearing out too fast.

He stresses how safety matters most. Using top-quality parts meets safety standards and avoids problems on the road. Transparency about what your truck needs prevents unexpected issues.

John suggests making these checks part of your routine care for your diesel truck. It’s not hard, but it helps avoid big repairs later.

Comparing different systems shows John’s advice is solid. While no system is perfect, following his tips can save time and money long-term.

For diesel truck owners wanting their vehicles to perform at their best, John believes taking care of your exhaust system is key. Following his guidance will help keep your truck running strong without breaking the bank.

FAQs

What are some common problems with turbo back exhaust systems?

Common issues with turbo back exhaust systems include performance exhaust issues, diesel exhaust problems and troubles related to the accelerator and spool up process due to turbos or quattro features.

How can I troubleshoot these turbo back exhaust issues?

To troubleshoot these issues, you need a good understanding of how the system works including knowledge about the flow of exhaust gases, gasoline usage and each component’s role in overall function.

Can I fix my own turbo back exhaust problems?

Yes, it is possible to fix your own turbo back exhaust problems like leaks using an Exhaust leak repair kit but it requires a certain level of technical expertise in system upkeep and custom exhaust maintenance.

How do I maintain my Turbo Back Exhaust System properly?

Proper maintenance includes regular checks on all components for wear or damage, ensuring that your turbocharger is functioning correctly as well as adhering to best practices for general care of your vehicle’s entire system.

Where can I find more resources on troubleshooting and maintaining my Turbo Back Exhaust System?

There are various online guides available that provide detailed instructions on troubleshooting common errors and providing tips for effective maintenance. You may also consult professional services specializing in this field if you need further assistance.