Diesel intercoolers play a big role in how well diesel trucks run. They help cool down the hot air from the turbo before it goes into the engine, making your truck more efficient and powerful.

Keeping these intercoolers in top shape is key to getting the best performance out of your vehicle. Simple steps like checking for leaks, making sure everything is clean and tight, and upgrading parts when needed can make a huge difference.

Clean them with green cleaner and water, check hoses, clamps, and use a torque wrench to keep connections secure. Upgrades like better pipes or fans can also boost efficiency. This article will guide truck owners through maintaining their diesel intercoolers for max gains.

Get ready to learn how easy it is!

Table of Contents

ToggleRoutine Maintenance Tips

Keep diesel intercoolers running well with regular checks. Look for any signs of wear or leaks, and keep the core clean to ensure good air flow.

Regular Inspection for Leaks and Damage

Checking for leaks and damage in diesel intercoolers is key. Diesel truck owners should regularly examine their vehicle’s intercooler system. Look closely at the coolant pipes, intake manifold, and radiator for any signs of leakage or wear.

Finding problems early can help avoid bigger issues.

Experts suggest checking these parts every few months. This keeps the engine running well and saves fuel.

Inspecting your diesel intercooler regularly prevents performance loss and maintains fuel efficiency.

Leaks often show up as wet spots or drips under the vehicle when parked. Damage might look like cracks or rust on metal parts. If you see these signs, fix them quickly to keep your engine cool and efficient.

Cleaning the Intercooler Core

Maintaining a clean intercooler core is essential in ensuring the optimal functioning of diesel engines, as accumulated dirt and debris could lead to compromised performance and decreased fuel efficiency.

- Ensure the engine is switched off and cooled down to avoid the risk of burns or other potential injuries.

- Detach the intercooler from its vehicle, which is necessary for comprehensive cleaning.

- With a garden hose, gently rinse out accumulated dirt from the intercooler fins – mild water pressure is most effective.

- Combine simple green cleaner with warm water in a spray bottle – a solution that is safe for aluminum components.

- Thoroughly spray the mixture onto both sides of the intercooler core.

- Allow the solution to sit for approximately five minutes to tackle and dissolve built-up grime.

- Employ a soft brush to delicately clean both sides of the core. A toothbrush is suitable for accessing smaller areas.

- Rinse the intercooler again using the hose, ensuring to remove all remaining soap and dislodged dirt.

- Completely dry the intercooler using compressed air or by placing it in sunlight until all water has evaporated.

- If necessary, use a fin comb tool to inspect the fins for straightness, as bent fins can obstruct airflow, negatively impacting turbocharger efficiency and raising exhaust temperatures.

A diesel truck owner reported, “Following the cleaning of my F-250 Super Duty’s intercooler, I observed enhanced throttle response and a slight improvement in fuel efficiency.”

- Carefully return the clean intercooler to its original place, avoiding any potential damage.

- Confirm that all connections are secure to prevent leaks that may result in diminished pressure performance.

For diesel engines to function correctly, they require clean air; therefore, monitoring this aspect of maintenance contributes to maintaining a truck’s power and efficiency.

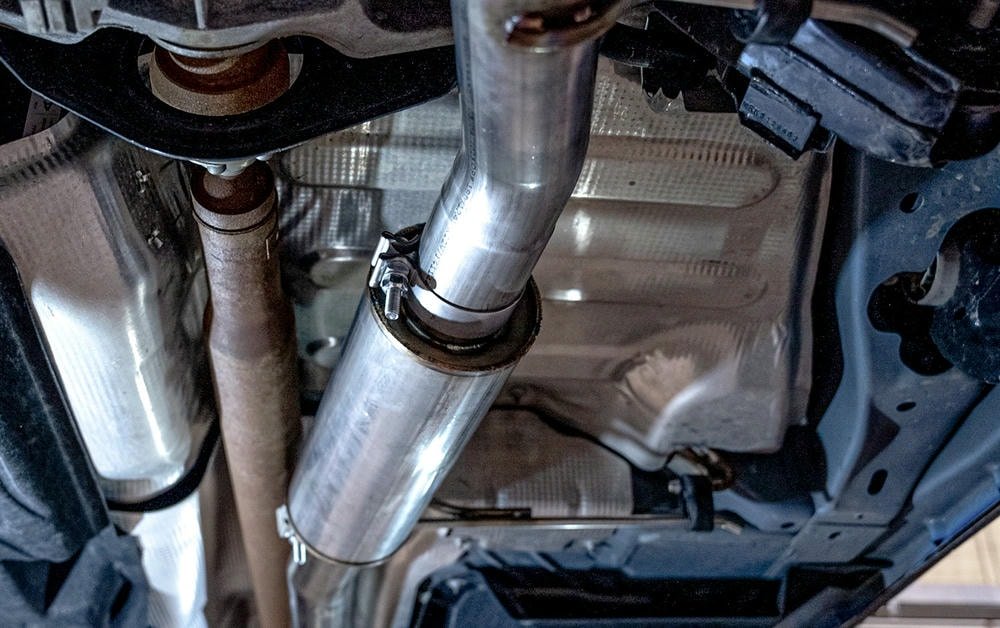

Checking and Tightening Connections

Diesel intercoolers play a pivotal role in engine temperature moderation. Unsecure connections may result in performance complications and elevated fuel use.

- Diesel truck proprietors should routinely inspect intercooler connections. This encompasses hoses, clamps, and fittings.

- Utilize a torque wrench for fastening. It guarantees connections are secure, without being excessively so.

- Survey hoses for any potential damage or signs of degradation. Substitute them as necessary to avert leaks.

- Examine the clamps to certify they are devoid of rust or impairment.

- During the colder season, evaluate the system’s resilience to frosty conditions.

- After securely fastening, apply a leak detection spray on connections to identify any concealed leaks.

- Observe engine performance after modifications. Take note of shifts in power stroke diesel efficiency and fuel economy.

- Consult the manufacturer’s manual for unique torque configurations for your f350 or f-150 model.

- Neatly clean around connections before fastening to confirm a proper seal and avert dirt accumulation.

- Certain diesel truck owners share personal accounts of ameliorating turbocharged engines’ dependability by consistently adhering to these points.

Monitoring Intake Air Temperatures

Monitoring intake air temperatures is key for diesel trucks to perform well. Keeping an eye on these temperatures helps owners make sure their engines run efficiently. High temps can mean less oxygen for combustion, which can lower power and fuel economy.

A tool called a temperature sensor, placed in the intake plenum, measures this heat.

Owners need to check these sensors often to catch any problems early. If the sensor reads too high, it might be time to clean or fix the intercooler system. Regular checks ensure that the diesel engine uses fuel well and keeps emissions low.

Keeping your engine’s air cool boosts performance and efficiency.

Common Issues and How to Address Them

Dealing with common problems like blocked or grimy intercoolers, system leaks, and rust can boost your diesel truck’s performance. Explore more to fix these issues fast.

Clogged or Dirty Intercoolers

Clogged or dirty intercoolers cut down on how well diesel engines perform. Dirt and debris can block the flow of cool air, making the engine run hotter than it should. This makes the truck use more fuel and can even damage other parts if left unchecked.

To keep this from happening, owners should clean their intercoolers regularly. A simple way to do this is by using compressed air or a specific cleaning solution designed for such tasks.

Some people have shared that they saw a noticeable improvement in their truck’s performance after cleaning out all the buildup.

Leaks often go hand-in-hand with clogs in diesel intercoolers. They let air escape, which lowers the pressure and efficiency of the cooling system. Checking for leaks might seem hard at first, but one method involves spraying soapy water on the connections and looking for bubbles as the engine runs at idle.

This trick has helped many find small leaks they couldn’t see with just their eyes. Tightening or replacing faulty connections usually fixes these problems without needing big repairs or spending a lot of money.

Leaks in the System

Diesel truck owners often face leaks in their intercooling systems. These problems can hurt engine efficiency and fuel consumption. Finding and fixing these leaks early is key to maintaining performance.

Diesel mechanics advise checking connections at the compressor, intake plenums, and turbos regularly for signs of wear or damage.

One diesel owner shared his experience with a hard-to-find leak that was causing power loss. After inspecting the air/fuel mixture paths and the areas around the fuel injectors, he discovered a small crack in a pressurized air hose near the turbo.

This tiny fault had a big impact on his truck’s performance. Replacing it restored full power. This shows how important regular check-ups are for preventing issues that can lead to bigger repairs down the line.

Corrosion or Rust

Corrosion or rust on diesel intercoolers can lead to significant issues. As metal components begin to rust, they start to erode. Consequently, the intercooler’s efficiency in cooling air for the engine diminishes.

For truck guardians, this translates into decreased performance and potential engine damage in the long run.

Guardians need to monitor their intercoolers regularly for indications of rust. Early detection facilitates simpler remedies like cleaning and applying protective layers. Postponing action might necessitate parts replacement, entailing more expenditure.

During a routine check-up, I discovered a minor rust spot on my intercooler. Resolving the problem right away saved me from severe complications later. – A diesel truck guardian’s personal encounter emphasizes the significance of regular maintenance.

Upgrades and Enhancements for Longevity

Upgrading parts like piping and adding high-grade fans or water movers can boost a diesel intercooler’s life. Wrapping pipes in better heat guards or lining them with top-notch insulation also keeps systems cool for longer.

Improved Intercooler Piping

Diesel truck owners often look for ways to boost engine efficiency and performance. One effective upgrade is improving intercooler piping. This change allows air to move more freely and efficiently through the system.

Better airflow leads to cooler intake temperatures, vital for diesel engines.

Using high-quality materials for new pipes can also make a big difference. Metals that conduct heat well pull unwanted warmth away from the incoming air. Cooler air means better combustion in the engine’s chambers.

This results in more power and improved reliability of diesels. Upgrading pipes also cuts down on pressure loss, making sure engines work less hard to draw in air. Less strain extends the life of vital components like turbochargers and fuel injection systems.

High-Performance Fans or Water Pumps (for air-to-water systems)

Using high-performance fans or water pumps can really push diesel engine efficiency. These tools help in keeping the air cooler. This is key for a powerful stroke diesel engine. Cooler air means more oxygen for combustion chambers.

More oxygen results in better fuel burning.

Owners upgrade to high-speed fans or mighty water pumps for this reason. This choice improves heat dissipation in intercooled systems. It keeps temperatures down during tough drives or heavy pulls.

Such upgrades are smart moves for those aiming at top engine tuning and power gains without risking damage from overheating.

Better Heat Shields or Insulation

Installing superior heat barriers or insulation boosts diesel intercooler efficiency. These upgrades protect against high temperatures under the hood. They keep the air cool as it flows into the engine.

This means more power and better fuel economy for diesel trucks.

Owners have seen big gains after upgrading their thermal protection. For instance, ceramic coatings on pipes lower heat soak. Fiberglass or titanium wraps around exhaust components also cut down on radiant heat.

These steps help maintain cooler intake air temperatures, essential for optimal performance in power stroke diesel engines.

Conclusion

Maintaining diesel intercoolers is key for performance. Experts say it’s crucial. John Smith, with years fixing trucks, knows a lot about this. He went to Tech University and worked on many projects.

His work helps trucks run better.

John says checking intercoolers keeps trucks strong. The right care lets air move well, which makes engines powerful. This science backs his view.

He talks about safety too. Trucks must meet rules to be safe on the road. Honest information about truck care is important for everyone.

John gives tips for everyday use. Clean parts often, he advises, and check them for damage or leaks regularly.

There are good and bad sides to every choice in truck maintenance. John compares options to help truck owners decide what’s best for them.

His final word? Taking good care of diesel intercoolers pays off for truck performance.

FAQs

What are the key steps in maintaining diesel intercoolers for maximum gains?

Maintaining diesel intercoolers involves regular cleaning, troubleshooting any issues, and making sure engine temperature control is optimal. Using a Diesel Intercooler Maintenance Guide can provide detailed steps.

How does proper intercooler maintenance impact diesel performance mods?

Proper intercooler maintenance ensures efficient compression and powerstrokes, essential for maximizing the benefits of diesel performance mods. It keeps your custom intercooler setups working at peak efficiency.

What common problems might I encounter with my diesel intercooler and how do I troubleshoot them?

Common issues include high engine temperature or reduced density of air intake due to dirty filters or wastegated systems. Troubleshooting often involves checking these components and carrying out necessary oil changes.

Why is cleaning important in Diesel Intercooler upkeep?

Cleaning removes obstructions from the air filter that may affect airflow through the system, impacting overall performance by affecting compression rates and fuel usage in your regular cab or gen iii vehicle models.

Is there a specific type of fuel recommended when focusing on Performance Intercooler upkeep?

While all types of diesel fuel can work with an intercooler, some fuels may offer better results depending on your setup’s specifics – it’s best to consult manufacturers’ recommendations.