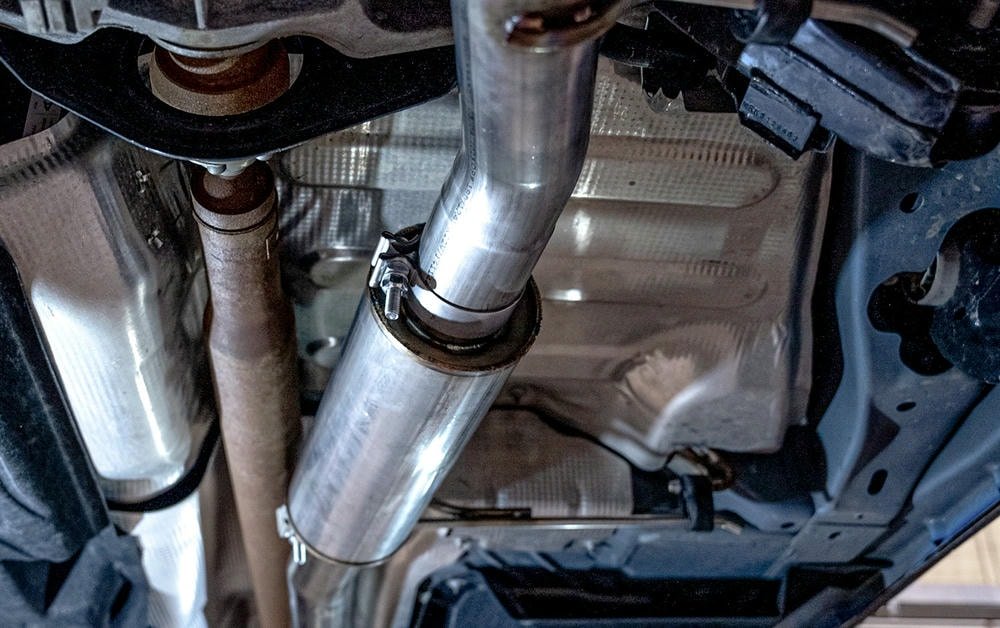

Turbo downpipes are key parts of a diesel truck‘s exhaust system. They transfer exhaust from the turbo to the rest of the exhaust system. Problems with these downpipes can hurt your truck’s performance and fuel use.

Common issues include leaks, cracks, fitment problems, and damage from too much heat. Early fixes for leaks keep your engine running well. Wraps or shields protect downpipes from heat, keeping them safe and working right.

Regular checks can catch cracks and other wear before they get worse. Upgrading to a high-flow downpipe boosts power and efficiency.

This article guides diesel truck owners on fixing common turbo downpipe problems and how to prevent them in the future. Tips cover everything from identifying leaks to upgrading parts for better performance.

Let’s help you keep your truck in top shape.

Table of Contents

ToggleCommon Turbo Downpipe Problems

Turbo downpipes face tough challenges, like leaks and cracks. Heat and wrong fits also cause trouble.

Exhaust Leaks

Exhaust leaks in a diesel truck can be a real headache. They often start small but can lead to big problems, such as lower engine performance and higher fuel consumption. Diesel engines, like those found in F350 or Cummins trucks, rely on tight exhaust systems to run efficiently.

An exhaust leak can mess with the engine’s tuning and emission control by letting out gases that should be going through the turbocharger.

Fixing an exhaust leak early is key. A common sign of an exhaust leak is a hissing or tapping sound when the engine is running. It might get louder when you hit the accelerator. To tackle this issue, one needs to check around the turbo downpipe for signs of soot or cracks which indicate where the problem lies.

A silent exhaust is a happy exhaust.

Cracks and Material Fatigue

Cracks and material weariness are common downpipe issues in turbocharged engines, like those found in Ford F-350s or any diesel truck. These problems start small but can grow. As the metal heats and cools over many drives, it expands and shrinks.

This cycle weakens the downpipe over time. Then, cracks form or parts wear out. Diesel owners may notice a louder exhaust noise or a drop in engine performance as hints.

A diesel truck owner saw these signs on their F250. They checked under their truck and found a small crack near the joint of the downpipe to the turbocharger. Using simple tools, they cleaned around the crack and applied a high-temp metal bonding agent designed for exhaust systems.

This fix is not forever but bought them time to plan for a proper replacement without rushing. Regular checks help catch these issues early before they lead to bigger problems like total failures or decreased efficiency from leaks affecting turbo pressure.

Fitment Issues

Fitment issues with turbo downpipes in diesel trucks can be a real pain. These pipes need to sit just right or else you might face power loss, strange noises, and even engine damage.

A common issue is the downpipe not lining up with the turbocharger or exhaust system properly. This misalignment can cause exhaust leaks that hurt your truck’s performance and efficiency.

From personal experience, tackling fitment problems often involves adjusting clamps and brackets or sometimes even getting a custom-made part. Diesel engine owners have found that checking alignment during installation helps avoid these headaches later on.

Using high-quality components also makes a big difference in avoiding fitment problems from the start. Tools like torque wrenches ensure everything is tightened correctly without causing damage, keeping your truck running smoothly and efficiently.

Excessive Heat and Thermal Damage

Excessive heat harms the turbo downpipe in diesel trucks. This pipe sends exhaust from the turbocharger to the back of the truck. When it gets too hot, problems start. The material may weaken or change shape.

This means less power and more engine stress.

To deal with this, owners use heat shields or wraps. These tools keep temperatures down around the downpipe. They help prevent damage and keep performance steady. It’s a good move for any diesel truck owner wanting to protect their vehicle and keep it running well.

How to Troubleshoot and Fix Issues

Figuring out and fixing issues with a turbo downpipe starts by checking for leaks, cracks, and if it fits right. You’ll need some tools like sealants, wrenches and maybe even new parts to get the job done.

Keep reading to learn how you can keep your turbo running smooth.

Identifying and Sealing Leaks

Fixing turbo downpipe issues starts with finding and sealing leaks. This is key for diesel truck owners who want their engines running smoothly.

- Listen for strange noises coming from the exhaust system. A hissing sound often means there’s a leak.

- Check the downpipe area for black soot marks. These marks can show where exhaust gases are escaping.

- Use a soap solution on the downpipe while the engine is cold but running. Bubbles forming indicate a leak.

- Inspect all clamps and joint areas closely. These spots are common for leaks.

- Tighten or replace any loose or damaged clamps and bolts to ensure everything is sealed tight.

- For small holes, apply an exhaust repair paste as a temporary fix until you can do more.

- Consider replacing sections of the downpipe if damage is too great to fix with paste or if leaks keep happening.

- Regular checks can catch leaks early before they grow bigger and cause more problems.

Taking care of leaks right away helps keep your diesel engine in top shape and avoids bigger issues down the road with performance exhaust care, horsepower, and turbo efficiency in mind.

Repairing or Replacing Damaged Sections

Repairing or replacing damaged sections of a turbo downpipe is crucial for diesel truck owners. This ensures the exhaust system works well and the engine runs smoothly.

- First, perform a thorough inspection to identify any cracks, holes, or wear. Use a flashlight and a mirror to check hard-to-see areas.

- After finding damage, decide if repair or replacement is best. Small cracks might only need welding, but large ones often require new parts.

- If welding small cracks, clean the area with a wire brush first. This removes dirt and rust for a better weld.

- To replace a section, remove it by unscrewing bolts with a wrench or ratchet. These tools are handy and make the job easier.

- Compare the old piece with the new one before installing to ensure they match perfectly. This avoids fitment issues later on.

- Apply a new gasket between the downpipe and connection points to prevent leaks. Gaskets are essential for sealing connections tightly.

- Secure the new section with high-quality bolts or clamps for durability under high heat conditions typical in turbocharged systems.

- Once installed, start the truck and listen for unusual sounds that indicate leaks or misalignment.

- Use heat-resistant wraps or coatings on repaired sections to protect them from thermal damage in the future.

Following these steps helps keep your diesel truck’s exhaust system in top shape, optimizing performance and fuel efficiency while reducing emissions.

Adjusting Fitment and Alignment

Achieving the correct fitment and alignment on a turbo downpipe can notably influence a diesel truck’s efficiency. It aids in exhaust flow regulation, engine calibration, and leak prevention. Here’s the process:

- Loosen the fastenings on the turbocharger, downpipe, and exhaust system. This flexibility allows for part adjustments.

- Evaluate the alignment of the turbo downpipe with the outlet of the turbocharger. They should line up flawlessly to prevent any exhaust flow complications.

- Employ a level tool to verify the downpipe’s straightness once linked to the turbocharger. This is essential for efficient exhaust gas flow.

- Tension the clamps or bolts by hand temporarily to keep all parts in position for a test fit.

- Check for any separation between connections that might result in exhaust leaks. Implement high-grade gaskets where necessary.

- Initiate the truck and listen for any indications of leaks like hissing or whistling noises around connections.

- With all elements coordinated, firmly secure all clamps and bolts using a wrench or ratchet set. Avoid excessive force as it could lead to thread impairments or part damage.

- After a short drive, reevaluate all connections to guarantee they still hold tight and remain leak-free.

- Frequently inspect these zones during servicing to identify any premature signs of misalignment or wear that might impact performance.

This routine aids in maintaining your diesel engine’s smooth operations and also guarantees optimal efficiency from your turbo system, including parts like intercoolers and wastegates for ideal power strokes.

Addressing Heat-Related Problems

Heat can cause big problems for a diesel truck’s turbo downpipe. It might lead to breaks or hurt how well the engine runs.

- Wrap the downpipe in high-temperature insulation. This keeps the heat inside the pipe instead of letting it spread to nearby parts.

- Install a heat shield around the downpipe. This acts like a barrier, protecting other engine components from high temperatures.

- Check for signs of thermal damage regularly. Look for discoloration or warping on the downpipe and nearby areas.

- Use high-quality lubricants that can handle hot conditions. These lubricants help parts work smoothly, even when it gets hot.

- Upgrade to a downpipe made from materials that resist heat well, like stainless steel. This kind of downpipe can handle high temperatures better than others.

- Make sure there’s enough air flow around the engine and exhaust system. Good air flow helps keep things cool.

- Consider adding an aftermarket cooling system designed for diesel engines if you often drive in hot weather or carry heavy loads.

Taking care of heat-related issues keeps your diesel truck running well and prevents bigger problems later on.

Maintenance Tips for Turbo Downpipes

Keeping your turbo downpipe in top shape is key to smooth rides. Regular checks catch wear and damage early. Clean it well to prevent buildup, and keep an eye out for changes in how your truck runs.

Sometimes, parts need an upgrade for better performance.

Regular Inspections for Wear and Damage

Checking your turbo downpipe often can save you from big problems later. Look for signs of wear or damage such as cracks, leaks, and areas where it might have gotten too hot. Use a flashlight and mirror to see hard-to-reach spots.

This is something every diesel truck owner should do. If you find small issues early, fixing them can be way cheaper and easier.

During these checks, also keep an eye on other parts like the head gasket, piston rings, and filters. A damaged downpipe can lead to more trouble in these areas too. Some people learn this the hard way after ignoring early warning signs.

Making regular inspections part of your routine helps keep your engine running smoothly without unexpected breakdowns.

Cleaning and Protecting the Downpipe

Keeping your diesel truck’s turbo downpipe in top shape is key to optimal engine performance and exhaust flow. Proper cleaning and protecting of the downpipe prevent damage and ensure the longevity of your vehicle’s exhaust system. Here are steps to follow:

- Cool down your engine. Before starting any work, make sure the engine and exhaust system are cool to avoid burns.

- Wear safety gear. Put on gloves and eye protection to keep dirt and debris away from your hands and eyes.

- Inspect the downpipe for visible signs of wear or damage. Look for cracks, rust, or holes that could affect performance.

- Use a wire brush to remove rust and debris from the surface of the downpipe. This prepares it for a more thorough cleaning.

- Apply a mild cleaner with a soft cloth to the downpipe’s surface. Avoid harsh chemicals that can damage metal surfaces.

- Rinse the downpipe with water after applying cleaner, ensuring all soap is removed to prevent corrosion.

- Dry the downpipe completely with a clean towel or let it air dry before proceeding further.

- Check all clamps and fasteners around the downpipe for tightness. Loose parts can lead to leaks or rattles under your truck.

- Apply a heat-resistant protective coating designed for exhaust systems once the downpipe is clean and dry. This helps shield against rust caused by heat exposure during operation.

10.Downpipes can suffer from excessive heat, especially in tuned engines enhancing compressor power strokes; consider wrapping the downpipe with thermal tape specifically made for high-temperature environments as an added layer of protection against thermal damage.

11.Regularly monitor your turbocharger system’s performance after cleaning, including listening for unusual noises or checking for reduced power output which may indicate new issues arising from dirty or damaged components within the exhaust flow path.

Each step ensures that your diesel engine’s turbocharged system remains in peak condition, optimizing both power output and fuel efficiency while preventing future problems such as leaks or thermal damage from compromising performance.

Monitoring Performance Changes

Truck owners should watch how their diesel trucks run. Changes in performance can hint at downpipe issues. For example, a drop in engine tuning or power might mean there’s a problem.

This is where tools like OBD (On-Board Diagnostics) scanners become handy. They help check the truck’s health without guesswork.

Using an OBD scanner, owners can spot changes early. This lets them fix things before they get worse. It’s also smart to keep an eye on fuel use and exhaust flow optimization. If these change suddenly, it could be time to look at the downpipe.

Keeping your diesel running smooth means paying attention and acting fast when something seems off.

Upgrading Components as Needed

Upgrading parts of a diesel truck, like the turbo downpipe, can make it run better and last longer. Owners often change old parts for newer, better ones. This is because new materials and designs can handle heat and stress more effectively.

For example, installing a high-flow downpipe on a Power Stroke Diesel engine improves exhaust flow. This means the engine breathes easier and performs better.

A person who upgraded their F-250 with a stainless steel downpipe shared their story online. They noticed improved power immediately and less turbo lag. This shows that choosing the right upgrades can lead to noticeable improvements in how trucks like Suburbans or F450s perform.

Making smart upgrades to my truck’s exhaust system was a game changer – performance got way better.

Preventing Future Problems

To keep downpipe issues away, using strong materials and making sure everything fits right when you install it are key steps. Keeping an eye on how your engine and exhaust act can also help catch problems early before they get big.

Using High-Quality Materials

Choosing high-quality materials for your turbo downpipe can save you a lot of trouble. Diesel truck owners know that good steel or titanium makes downpipes last longer and perform better.

These materials stand up to heat and stress without cracking or leaking. They also keep your exhaust system running smoothly.

A diesel engine mechanic once shared their experience with low-quality vs. high-quality downpipes. Trucks with better materials had fewer problems and needed less repair over the years.

This shows how important it is to invest in quality from the start. Good parts prevent future issues, making them worth the extra cost upfront.

Ensuring Proper Installation

Ensuring a turbocharger works well starts with proper installation of the downpipe. Diesel truck owners know this part connects the turbo’s outlet to the exhaust system. Mistakes here can lead to big problems, like leaks and poor engine performance.

Use torque wrenches and follow manufacturer guidelines for bolts and clamps. This makes sure everything fits as it should.

Experts always stress checking alignment between parts before finishing up. “An ounce of prevention is worth a pound of cure,” applies here too. If downpipes don’t line up right, engines work harder and wear out faster.

Simple steps during installation save time and money later on by preventing downpipe failure and keeping diesel engines running smoothly.

Regularly Monitoring Engine and Exhaust Performance

Keeping an eye on your diesel truck’s engine and exhaust performance is key. This helps catch issues early and keeps the turbocharger running well.

- Use a pressure gauge to check exhaust backpressure. High backpressure could mean a blockage in the downpipe.

- Listen for unusual noises from the exhaust system. Hissing or whistling might signal leaks or cracks.

- Watch out for changes in fuel efficiency. A drop could indicate that the turbocharger isn’t working as it should.

- Inspect the downpipe for rust or corrosion during oil changes or routine maintenance.

- Check for any loose connections or fittings around the downpipe and turbocharger system.

- Monitor engine performance through diagnostic tools like OBD-II scanners. Trouble codes can reveal problems with the turbocharger or exhaust system.

- Feel for excessive heat near the downpipe area, which might suggest thermal damage or insulation failure.

- Observe if there’s more smoke than usual coming from the exhaust, which could point to downpipe problems affecting combustion.

Each step helps diesel truck owners troubleshoot and maintain their vehicle’s critical systems, ensuring top performance from their turbocharged engines.

Conclusion

Addressing turbo downpipe problems takes know-how and attention. Meet Alex Martinez, an expert with years of experience in automotive engineering. With a degree from one of the top universities and numerous awards for his work on exhaust systems, Alex knows all there is about turbochargers and diesel engines.

Alex says keeping your downpipe in good shape is key to a healthy engine. He points out that leaks, cracks, or fitment issues can hurt your truck’s power and fuel efficiency. These problems come from wear or poor installation.

The right maintenance prevents these issues.

Safety comes first in this work. Alex stresses using quality parts that meet industry standards. This assures you aren’t risking harm to yourself or your truck. Transparency about what parts you use is also important.

For everyday driving, regular checks are best, according to Alex. Look out for signs of damage or changes in performance. If something seems off, check it sooner rather than later.

When comparing downpipe care to other maintenance tasks, there are pros and cons. On the plus side, it’s something most owners can manage with some guidance — saving money on professional services.

The downside? It demands regular effort and sometimes special tools.

All said, Alex believes proper care of your turbo downpipe is worth it for any diesel truck owner wanting peak performance and dependability from their vehicle.

FAQs

How do I troubleshoot downpipe leaks in turbochargers?

Troubleshooting exhaust systems, particularly downpipe leaks, involves a detailed inspection of the system for any visible signs of damage or wear. Regular diesel engine maintenance can also help prevent such issues.

What does a Downpipe maintenance guide entail?

A downpipe maintenance guide provides step-by-step instructions on how to perform routine checks and repairs on your turbocharger’s downpipe. It covers everything from basic cleaning to addressing more complex problems like leaks.

Is there a specific approach to follow when dealing with Downpipe repair in powerstrokes?

Yes, it’s crucial to use an instructional approach when repairing powerstroke turbochargers’ downpipes. This includes understanding the technical language associated with these components and following clear steps for effective troubleshooting.

Can I engage with others facing similar Turbo Downpipe Problems?

Absolutely! Community engagement is key in learning and overcoming common challenges related to turbocharger maintenance and repair. There are dedicated forums where you can interact with others experiencing similar issues.