Turbo downpipes are vital parts of the exhaust system in vehicles with turbocharged engines, like many diesel trucks. They hook up the turbocharger to the rest of the exhaust and help get rid of gases quickly.

This is key for making trucks run stronger and more smoothly. Better exhaust flow from these downpipes can boost engine power, which means truck owners see gains in horsepower and torque.

Made with fewer bends and often wider than standard pipes, high-performance downpipes also include features like catalytic converters to cut back pressure. That helps engines perform at their best, improving fuel usage and reducing turbo lag.

This article explains what turbo downpipes are, how they work, and why they matter for diesel truck owners looking for more power under the hood. Get ready to learn about a simple upgrade that could make a big difference.

Table of Contents

ToggleUnderstanding Turbo Downpipes

Turbo downpipes are key parts of a vehicle’s exhaust system. They help move exhaust gases away from the turbocharger to improve performance.

Definition and Functionality

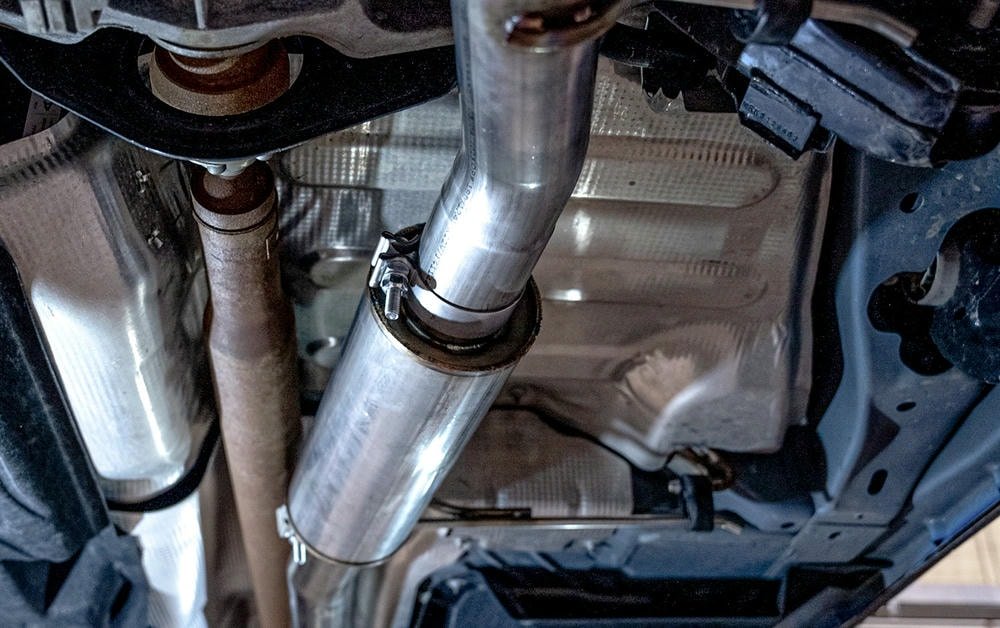

A turbo downpipe is a key part of the exhaust system in turbocharged vehicles. It connects the turbo’s outlet to the rest of the exhaust. This pipe plays a huge role in how well gases flow from the engine.

Better flow means less back pressure, which helps the engine work easier.

The right downpipe can significantly boost performance by improving exhaust flow.

Downpipes often have a catalytic converter to reduce pollution. They are made from materials like stainless steel, which stands up well to heat and rust. Changing to a high-performance downpipe can increase power and efficiency because it lets exhaust gases move more freely.

Components of a Turbo Downpipe

Understanding the parts of a turbo downpipe is crucial for diesel truck owners who want to boost their vehicles’ performance. Every component plays a specific role in improving exhaust flow and enhancing engine efficiency. Here’s a closer look at what makes up a turbo downpipe:

- Pipe itself: The main tube that carries exhaust from the turbocharger to the rest of the exhaust system. Its design can vary, but it usually features mandrel bending for smooth airflow.

- Flanges: Metal plates that connect the downpipe to the turbocharger and the rest of the exhaust system securely. They ensure no leaks happen at these critical points.

- Oxygen Sensors (O2 sensor): These monitor how much oxygen is in the exhaust, helping adjust air-fuel ratios for optimal combustion. Diesel trucks might have multiple sensors along the downpipe.

- Catalytic Converter (catalyst): This device reduces pollutants by converting toxic gases like carbon monoxide into less harmful emissions such as carbon dioxide and water vapor.

- Flex Section: A flexible piece of pipe that allows for some movement between the engine and exhaust system, reducing stress and preventing leaks.

- Heat Shields: Parts made from high-temperature materials that wrap around sections of the downpipe to keep heat away from sensitive vehicle components.

- Wastegate Connection: Some downpipes have spots for wastegates, which control boost pressure in the turbo system, avoiding damage from too much pressure.

- Mounting Hardware: Includes bolts, nuts, and brackets needed to secure the downpipe in place firmly.

Each part of a turbo downpipe contributes to better diesel performance by aiding in faster expulsion of exhaust gases and reduced backpressure on the engine. Whether upgrading for more power or ensuring everything runs smoothly, knowing these components helps diesel truck owners make informed decisions about their exhaust systems.

How Turbo Downpipes Connect to the Exhaust System

Turbo downpipes are crucial parts of a truck’s exhaust system. They link the turbocharger to the rest of the exhaust setup. This connection is key for getting rid of exhaust gases quickly and efficiently.

The downpipe starts at the turbine exit on the turbocharger. From there, it sends the gases through to either a catalytic converter or straight to the muffler and tailpipe, depending on the truck’s design.

These pipes play a big role in how well an engine performs. By improving gas flow from the turbo, they help make engines run smoother and more powerful. High-performance downpipes often replace stock ones because they are bigger or have less bends.

This simple change can lead to more horsepower and better fuel use in diesel trucks.

Benefits of Turbo Downpipes

Installing high-performance turbo downpipes can greatly improve your diesel truck’s engine efficiency. They allow for faster exhaust gas exit, which means the turbocharger works better and your truck gains more power and twist.

Improved Exhaust Flow

Turbo downpipes play a key role in improving exhaust flow. They are pipes that connect the turbocharger to the rest of the exhaust system. By using a wider pipe, they allow exhaust gases to leave faster.

This reduces back pressure on the engine and lets it breathe easier.

A smoother path for exhaust gases means better performance.

This upgrade is essential for diesel truck owners looking to boost their vehicle’s power and efficiency. With less obstruction, turbochargers spool up quicker, reducing turbo lag. This leads to gains in horsepower and torque, making your truck more responsive when you press on the gas pedal.

Enhanced Turbocharger Efficiency

Upgrading to a high-quality turbo downpipe can make a diesel truck’s engine run better. This part helps the turbocharger work faster by moving exhaust gases away more quickly. With less blockage, the turbo spins up swiftly.

This means trucks get to enjoy more power without waiting.

A good downpipe also reduces back pressure in the exhaust system. Less pressure lets the engine breathe easier, adding to its efficiency. Diesel truck owners often see their trucks perform better on the road and use less fuel too.

Through this simple upgrade, engines work smoother and last longer because they don’t have to fight against a choked exhaust system.

Potential Gains in Horsepower and Torque

Upgrading with a turbo downpipe can lead to impressive gains in horsepower and torque. This means diesel truck owners might see their trucks run faster and pull harder than before.

The science behind this involves better exhaust flow and reduced back pressure, allowing the engine to breathe easier. With these upgrades, it’s common to see improvements ranging from 10 to 25 more horsepower.

That’s like giving your truck a big breath of fresh air so it can perform better.

The increase in torque is also significant, making towing heavy loads smoother and improving overall acceleration. Imagine pushing the gas pedal and feeling an instant response without any lag.

This boost comes from the efficient removal of exhaust fumes through the upgraded pipe system, leading directly to more power at your disposal for every drive or haul you undertake.

Conclusion

Experts, like Dr. Alex Rivera with many years in engine tuning, shed light on turbo downpipes. Dr. Rivera has a deep history in mechanical engineering and works hard on exhaust system design.

This expert knows how to make engines run better.

Dr. Rivera points out that turbo downpipes are key for faster exhaust flow and better turbo work. These pipes make sure engines breathe out quickly, helping cars go faster and stronger.

Safety is also big for Dr. Rivera. He says quality downpipes follow strict rules to protect the air we breathe. Honest makers tell buyers exactly what they’re getting, which keeps everyone safe.

For daily use, this expert suggests choosing a downpipe that fits your vehicle’s needs well. Not all cars will see the same benefits, so picking the right one matters.

Dr. Rivera believes while these parts offer big power gains, there can be downsides like higher costs or more noise.

His final word? Turbo downpipes are worth it for those looking to boost their ride’s performance wisely.

FAQs

What is a turbo downpipe and what does it do?

A turbo downpipe is an integral part of custom exhaust setups, especially in engine tuning for performance enhancement. It’s designed to improve exhaust flow from the turbo compressor to the cat-back exhausts, increasing power output.

How do turbo downpipes enhance engine performance?

Turbo downpipes play a crucial role in enhancing engine performance by reducing compression backpressure on the exhaust side of the system. This allows faster expulsion of exhaust gases, leading to improved valve operation and reduced risk of detonation, ultimately resulting in a noticeable power increase.

Can installing a turbo downpipe affect my vehicle’s emissions standards compliance?

Yes, altering your car’s original exhaust system design with aftermarket parts like turbo downpipes might impact its emissions standards compliance. The catalytic converter, often incorporated into OEM downpipes, contains noble metals like platinum, palladium and rhodium that help reduce harmful nitrogen oxides and hydrocarbons released into the atmosphere.

Is there any difference between headers and turbo downpipes?

Headers are essentially another type of high-performance exhaust component used mainly in naturally aspirated engines while Turbo Downpipes are specific to forced induction systems where they connect the turbine outlet (hot side) to the rest of the exhaust system.

Are all turbo downpipes compatible with all car models such as Audi or M340i?

No necessarily! Compatibility depends largely on specific model designs and existing castings within each car’s unique setup which can vary significantly across different brands or even models within same brand.

What factors should I consider when choosing a suitable Turbo Downpipe?

When selecting an appropriate Turbo Downpipe for your vehicle you should consider several aspects including: material quality for heat transfer efficiency; size & shape (laminar vs turbulent); potential effect on emissions testing results; likelihood of ‘creep’ over time due to thermal expansion; compatibility with your specific vehicle model.