Installing coolant hoses and pipes is a key task for keeping diesel trucks running well. These parts help control the engine’s temperature by moving coolant through it. Getting ready for this job means gathering tools like wrenches, pliers, and screwdrivers.

It also involves safety gear and the right new hoses and pipes that fit your truck. Before starting, you must drain the old coolant to make room for new fluid. This step is important for your truck’s health.

Learning how to remove old hoses and put in new ones can seem tricky at first glance. Yet, with a clear guide, anyone can do it confidently. The process includes draining the cooling system properly, removing worn-out hoses gently, ensuring new parts fit correctly, securing everything tightly without leaks, and then refilling with fresh coolant.

After installing everything correctly comes checking work like looking for leaks and making sure the engine stays cool under pressure.

This article will walk readers through each step carefully but simply — perfect for diesel truck owners wanting to tackle this maintenance themselves. Let’s get started!

Table of Contents

TogglePreparation for Installation

Before starting the installation, gather all necessary tools like wrenches and screwdrivers, along with materials such as new coolant hoses and pipes. It’s also critical to wear safety gear like gloves and glasses, and make sure the vehicle is securely positioned on a flat surface.

Required Tools and Materials

Getting ready to install coolant hoses and pipes on a diesel truck requires the right tools and materials. This ensures a smooth DIY installation process.

- Wrench Set: For loosening and tightening hose clamps and fittings.

- Screwdrivers: Both flat-head and Phillips types come in handy for various clamps.

- Pliers: Needlenose pliers help remove small clamps without damage.

- Coolant Drain Pan: To catch the engine coolant when draining the system.

- New Coolant Hoses and Pipes: Match these components to the truck’s make and model for perfect fitment.

- Hose Clamps: Ensure having both replacement and spare clamps as they often wear out or break upon removal.

- Radiator Flush Solution: To clean out the cooling system before installing new hoses.

- Engine Coolant: Choose the correct type of coolant specified for diesel engines.

- **Bucket or Container***: Useful for mixing coolant with water if needed.

- Funnel: Helps in refilling the cooling system without spillages.

- **Rags and Towels***: For cleanup of any spilled coolant or water around the work area.

- **Protective Gear***: Gloves protect hands from sharp edges, while goggles safeguard eyes from splashes.

Each item plays a crucial role in ensuring that removing old components and fitting new coolant kits is a hassle-free task, leading to better engine temperature control and efficiency.

Safety Precautions and Vehicle Setup

Safety comes first, especially when working on diesel trucks. Getting ready to install coolant hoses and pipes requires attention to both tools and the work environment.

- Park the vehicle on a flat surface to ensure stability while working.

- Turn off the engine and wait for it to cool down before starting. Hot engines can cause burns.

- Gather all necessary tools like wrenches, screwdrivers, hose clamps, and new coolant hoses and pipes.

- Wear protective gear including gloves and safety glasses to keep hands and eyes safe from spills and debris.

- Disconnect the battery to prevent any accidental electrical shorts while working near engine cooling components.

- Drain existing coolant safely into a container for proper disposal or recycling, protecting the environment.

- Check the truck’s manual for specific steps on removing old hoses and pipes since each model can be different.

- Keep children and pets away from the work area to avoid accidents.

- Lay out all tools and replacement parts within easy reach but away from moving parts of the vehicle.

- Use a flashlight or work light if needed to see clearly in dark areas under the hood.

- Make sure all connections are tight after installing new hoses and pipes to prevent leaks.

- Double-check hose fittings are correct for your truck model to ensure they fit properly without forcing them into place.

Following these steps will help keep you safe while upgrading your truck’s engine cooling system with new coolant hoses and pipes.

Pre-installation Checklist

Before starting the installation of coolant hoses and pipes, diesel truck owners need a clear plan. This pre-installation checklist helps ensure that everything is ready for a smooth process.

- Gather all required tools including screwdrivers, pliers, and a wrench set. These tools help with removing old parts and securing new ones.

- Have new coolant hoses and pipes on hand. Check they match your truck’s model and engine type to avoid issues during installation.

- Collect materials such as fresh motor oil, coolant liquid, and hose clamps. These items are crucial for filling and sealing the system.

- Set up a safe workspace. Make sure the area is well-ventilated and flat to prevent any accidents or spills.

- Allow the engine to cool down completely before starting work. This prevents burns and other injuries.

- Wear protective gear like gloves and safety glasses to guard against spills and debris.

- Drain existing coolant from the system into a clean container for proper disposal or reuse if it’s still in good condition.

- Inspect old hoses, pipes, thermostats, valves, and radiators for wear or damage to identify if additional replacements are needed.

- Verify that you have a method for properly disposing of old coolant hoses, pipes, and used engine fluid according to local regulations.

- Prepare your vehicle by parking it securely and using brakes or wheel stops to prevent any movement during the installation process.

- Consult your truck’s manual for specific instructions related to the cooling system layout, especially for custom cooling setups in diesel engines that might have unique requirements.

This list aims at making DIY coolant hose installation safer and more effective by ensuring diesel truck owners are well-prepared beforehand.

Step-by-Step Installation Process

The installation process for coolant hoses and pipes involves several key steps to ensure your diesel truck’s engine keeps cool. First, you have to drain the old coolant from your vehicle’s system.

This step is important because it makes way for fresh coolant that will help in proper temperature regulation. Next, removing the worn-out hoses and pipes allows you to check for damage or wear that could affect cooling efficiency.

Installing new parts is next; here, precision matters as each hose and pipe must fit securely to avoid leaks. You also need to fasten connections tightly with clamps to keep everything in place.

Lastly, refilling with new coolant and getting air out of the system ensures your truck runs smoothly without overheating issues. Each of these steps requires attention to detail and safety precautions like wearing gloves and goggles since working with liquid-cooled systems can pose risks if not handled correctly.

Tools such as wrenches, screwdrivers, a drain pan for capturing fluid, and a funnel for adding coolant are essential throughout this procedure.

Draining the Coolant System

First, place a large container under the vehicle to catch the coolant. Make sure it is big enough to hold all the liquid that will come out. Then, find the radiator’s drain plug at the bottom.

Loosen this plug slowly to let the coolant flow into the container. Some diesel trucks might have a valve instead of a plug. In this case, turn the valve to open it and start draining.

Always wear gloves and goggles for safety.

After most of the coolant has drained out, close the valve or replace the plug tightly to avoid leaks. Now is a good time to check if any hoses are loose or damaged while everything is empty.

This step helps ensure your cooling system works well without any problems after installing new components like hoses and pipes dedicated for diesel trucks’ engines’ liquid-cooled systems.

Removing Old Hoses and Pipes

Removing old hoses and pipes is a key step in upgrading the engine cooling system of a diesel truck. Owners need to turn off the engine and let it cool down before starting. Wearing gloves can protect hands from antifreeze and sharp edges.

Using the right tools, like pliers or a wrench, they loosen clamps on the radiator hose and other coolant passages. Then, they gently twist and pull to remove each hose without damaging nearby parts.

One person learned this process while working on their own truck. They found marking each hose’s position helpful before removal to avoid confusion during installation of new parts.

This practical tip saved time and helped avoid mistakes that could lead to leaks or poor performance after installing new coolant hoses and pipes.

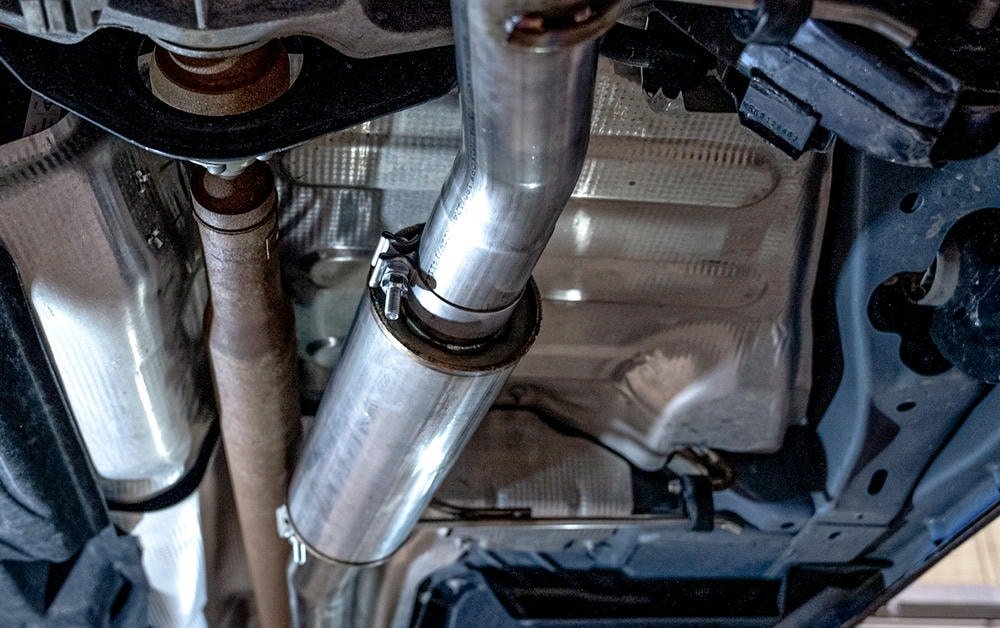

Installing New Hoses and Pipes

To install new coolant hoses and pipes on a diesel truck, start by comparing the new hoses with the old ones to ensure they match. Lay them out in the order they will be installed.

Use lubricant like coolant or soapy water on the fittings for an easier fit. Slide each hose into place, making sure it sits properly without any twists or kinks. For pipes, align them correctly with their respective connections before tightening.

Next, secure all clamps and fastenings firmly to avoid leaks. These include screw-type clamps or spring clamps found in engine cooling upgrades and coolant pipe assembly tasks. Do not over-tighten as this could damage the hoses or pipes.

Double-check each connection to make sure everything is snug and correctly positioned. This care ensures the anti-lock brake system, alternators, and other components relying on proper coolant circulation function well without overheating issues in vehicles.

Securing Connections and Clamps

After installing new coolant hoses and pipes on a diesel truck, ensuring tight connections is key. Use the right tools for this job: wrenches and screwdrivers are often needed. The clamps should be firm but not too tight.

Over-tightening can harm the hoses.

A diesel truck owner once said, “> Make sure every clamp clicks twice; it means they’re just right.” This simple check ensures that each connection is secure without causing damage to the hose or pipe.

Checking each clamp by hand helps find any that may need more adjustment before refilling with coolant.

Refilling the Coolant and Bleeding the System

Refilling the coolant begins with choosing the right fluid for your diesel truck. Owners must ensure they use a coolant that matches their vehicle’s requirements. Start by slowly pouring the coolant into the radiator.

Keep an eye on the level to avoid spills. It’s crucial not to rush this step to prevent air pockets from forming in the system.

Bleeding the system is next and vital for removing any trapped air. Diesel truck owners can do this by finding the bleed valve near the top of their engine, usually close to where they filled it with coolant.

Open this valve carefully while watching for when only coolant without bubbles comes out. This means there are no more air pockets in your cooling system, making it ready for safe operation again.

Through personal experience, most vehicle owners learn that patience during these steps keeps their trucks running smoothly without overheating issues.

Post-Installation Considerations

After installing new coolant hoses and pipes, it’s key to check the work. This means looking for leaks and making sure the engine runs well with its new parts.

Checking for Leaks

Checking for leaks is a crucial step after installing coolant hoses and pipes in a diesel truck. Drivers should start the engine and let it reach normal operating temperature. This action makes the cooling system pressurize, which helps to spot any leaks.

They must look closely at all hose connections and pipe joints, using a flashlight if necessary, for any signs of coolant escaping. Small drips or wet spots can signal a leak.

Always use your eyes and hands to check for leaks, as even small ones can lead to big problems.

If they find any leaks, turning off the engine immediately is essential. Tightening clamps or re-seating hoses may fix these issues. Sometimes, replacing defective components is needed if leaks continue.

Keeping an eye on the coolant level in the following days ensures everything stays sealed up tight.

Testing Engine Performance and Cooling Efficiency

After installing coolant hoses and pipes, diesel truck owners must test the engine’s performance and cooling efficiency. This ensures everything works as it should. Owners start the truck and let it run until it reaches normal operating temperature.

They watch the thermometer to make sure the engine does not overheat.

Next, they take their trucks for a test drive, pushing them to work hard enough to show any cooling system weaknesses. If the temperature stays stable and no leaks appear, this suggests a successful installation of coolant kits.

Testing helps identify any issues early, keeping trucks running smoothly and safely on the road.

Addressing Any Installation Issues

If diesel truck owners face problems during coolant hose and pipe installation, they should first check all connections. Loose or improperly fitted hoses can cause leaks. Use a flashlight to inspect every clamp and joint.

Sometimes air gets trapped in the system, making it work poorly. This needs bleeding out properly by following the guide for your specific vehicle.

For those who already tried fitting coolant pipes but still have issues, consulting the manual could provide answers. A pressure test on the cooling system might also help find hidden leaks that are not easy to spot with just eyesight.

If these steps don’t resolve the problem, seeking advice from a more experienced person could save time and prevent further damage to your truck’s engine.

Conclusion

Replacing hoses and pipes in a diesel truck’s coolant system is crucial. This task keeps the engine cool and running well. Experts like John Miller, with 20 years in auto repair, say doing it right matters a lot.

John has fixed thousands of trucks. He teaches mechanics too.

John talks about installing these parts correctly. This makes sure your truck does not overheat. It also saves money on future repairs.

He mentions safety first. Use gloves and glasses to protect yourself. Follow rules to keep everyone safe.

John suggests checking your work after installation. Look for leaks and test how the truck runs—these steps help catch issues early.

Comparing this project to others, John believes it offers great value—it helps your truck last longer without major problems.

His final advice? Taking time to install everything correctly pays off for diesel truck owners wanting a smooth-running vehicle.

FAQs

How can I fit coolant pipes in my car?

To properly install coolant hoses and pipes, you’ll need to follow a step-by-step installation guide that provides clear instructions for each task. This includes understanding the rationale behind each procedure, as well as any relevant background information.

What should I be aware of when installing a coolant kit?

Safety is paramount when working with cars, especially during tasks like installing a coolant kit. You should always adhere to best practices and precautions outlined in your installation guide to avoid potential hazards.

Can you provide some tips for installing coolant kits?

Certainly! Paying attention to detail is key – ensure precision and accuracy at every step of the process. Practical advice such as using proper tools or following specific sequences can help simplify the task.

Is it possible for me to undertake this task myself?

Absolutely! With supportive encouragement and an instructional tone throughout your educational content, even complex or technical subjects like this become manageable tasks that you can confidently tackle yourself.