Engine wiring systems are vital for diesel trucks to work right. They send power and signals throughout the vehicle to keep it running smoothly. This article will explain how owners can install these systems themselves, saving time and money.

First, one must gather tools like screwdrivers, wire cutters, and a multimeter. It’s also important to wear safety gear during the job.

Before starting, removing the old wiring is necessary by noting each connection’s place. Then, laying out the new harness correctly is crucial before securing everything in place with zip ties and electrical tape.

After installing the system, testing for any issues ensures everything works well.

Regularly checking your truck’s wiring can prevent future problems. This guide aims to make the process clear and manageable for diesel truck owners everywhere. Ready to learn?

Table of Contents

TogglePreparation for Installation

Before starting to put in a new engine wiring system, gathering the right tools and materials is key. This includes screwdrivers, pliers, wire cutters, and electrical tape. One also needs to take safety steps like wearing gloves and making sure the vehicle does not have power.

Setting up your truck properly before installing makes the job smoother.

Required Tools and Materials

Establishing an engine wiring system in a diesel truck mandates the correct tools and materials. This guarantees a seamless installation procedure and superior engine management. Here are the necessities for diesel truck proprietors:

- Screwdrivers: Various sizes required for disassembling panels and components.

- Wire strippers: For trimming and peeling electrical cables.

- Crimping tools: Crucial for fastening wire terminals and connectors.

- Soldering iron: Certain connections might necessitate soldering for longevity.

- Heat gun: Suitable for bonding heat shrink tubing around connections.

- Multimeter: To inspect electrical continuity and sensor operation during post-installation examinations.

- Flashlight or headlamp: Offers clear sight in restricted or dark areas.

- Electrical tape and heat shrink tubing: For shielding wired connections.

- Cable ties: To securely fix the wiring harness along its course.

- Fuse puller: Simplifies the removal or replacement of fuses, preventing harm.

- A new wiring harness customized for the specific model of the diesel truck.

By accumulating these tools and materials, diesel truck owners are prepared for a successful do-it-yourself wiring system installation, thus ensuring their engines perform at their best, whether adjusting fuel-injection systems in turbocharged engines or validating the smooth operation of all features like power windows, dome lights, turn signals, and cruise control.

Safety Precautions

Safety precautions are vital during the installation of an engine wiring system in a diesel truck. They ensure both the person installing the system and the vehicle stay safe. Here is what diesel truck owners need to do:

- Turn off the truck’s engine and remove the key from the ignition to stop electricity flow. This prevents electric shocks.

- Disconnect the battery before starting. This means taking off cables from the battery terminals, starting with the negative cable.

- Wear protective gear like gloves and safety glasses. These protect hands from sharp objects and eyes from sparks or debris.

- Keep a fire extinguisher nearby. This is crucial if an electrical fire starts.

- Use proper tools for making connections, such as wire crimpers for crimps and a wire stripper for removing insulation without damaging wires.

- Check all tools and equipment before use to make sure they are in good condition.

- Work in a well-ventilated area to avoid inhaling fumes from solvents or insulation.

- Make sure the area is dry and free of water to prevent electric shock.

- Organize wires and connectors properly to avoid confusion that could lead to incorrect connections, which might damage sensors or actuators.

- Follow guidelines for securing harnesses away from moving parts like alternators or sharp edges that could wear through insulation, leading to shorts or fires.

- Test all connections with a multimeter for electrical continuity before reconnecting the battery and starting the engine, ensuring everything is correctly installed.

Taking these steps helps prevent accidents and ensures a smooth installation process for DIY wiring system installations, focusing on safety first.

Vehicle Setup and Pre-installation Checklist

Installing engine wiring in a diesel truck requires careful preparation. Owners must gather the right tools and ensure safety before they start. Here is what one needs to do:

- Park the truck in a well-lit, dry area to avoid moisture issues with electrical systems.

- Disconnect the battery to prevent any electrical shocks or short circuits during installation.

- Gather all necessary tools including wire cutters, strippers, crimping tools, and a multimeter for electrical tests.

- Wear safety glasses and gloves to protect against accidental sparks or wire cuts.

- Check the condition of existing wires for signs of wear or damage that could affect new wiring.

- Make sure all required materials are at hand: new wiring harness, tape, cable ties, and any specific sensors and actuators for diesel engine performance.

- Confirm that the replacement wiring harness matches the truck’s make, model, and year for a proper fit.

- Review the engine control diagram to understand where each wire goes before removing anything.

- Ensure there is no fuel leakage in the area where work will take place since this poses a fire risk near electric work.

- Plan routing paths for new wires avoiding areas that get too hot or move parts like belts and fans.

Following these steps helps diesel truck owners prepare properly for installing an engine wiring system.

Step-by-Step Installation Process

The step-by-step installation process begins by removing the old wires in your diesel truck. You’ll then lay out the new wiring system, making sure each wire goes to the right place like sensors, third brake lights, and fuel injectors.

Removing the Old Wiring System

Removing the old wiring system from a diesel truck requires precision and care. Diesel truck owners often find this process vital for engine optimization and to prepare for custom wiring setups.

- Disconnect the battery to ensure safety. This prevents any electric shock or short circuits.

- Label each connection before removal. This helps identify where each wire should go during the new installation.

- Use a screwdriver to remove the panels covering the wiring harness.

- Carefully unplug all connectors, starting with the third brake light, taillights, and then headlights.

- Remove any securing ties or clamps holding the wiring harness in place.

- Gently pull out the main wiring harness from its pathway around the engine.

- For fuel-injected engines, disconnect the fuel injector wires with extra care to avoid damage.

- Unhook any switches, such as those for the windshield washer or heater, that are connected to the system.

- Keep an eye out for wear or damage on brake lines while removing nearby wires.

- Take out relays and check their condition; they might need replacement if faulty.

- Inspect areas around the trunk and under panels for hidden wires that need removal.

A diesel truck owner shared how labeling each connector before removal simplified reinstallation, preventing mix-ups and saving time during their engine wiring installation project.

Laying Out the New Wiring Harness

Laying out the new wiring harness is a key step in engine wiring installation. This process ensures all connections are ready for diesel truck owners to fit their engine systems accurately.

- Clear the area where you will work on your diesel truck. Make sure there’s enough space to lay out the new wiring harness without tangling.

- Identify each end of the wiring harness. Most harnesses have tags that help you know where each section goes.

- Spread the wiring harness across the engine bay, following the path of the old system. This helps in visualizing how it will connect to various components.

- Attach the main connectors to their matching parts on the engine block, such as sensors and actuators. These are crucial for engine diagnostics.

- Route the wires for the brake pedal and generators next, ensuring they follow a safe path away from hot or moving parts.

- Use cable ties to loosely secure the wiring along its route. This prevents damage and keeps everything organized until final adjustments are made.

- Double-check every connection point against your vehicle’s manual or a wiring diagram specific to your model. Accuracy here prevents issues later.

- Connect ground wires to their designated spots on the truck’s frame or engine block, establishing a reliable electrical ground.

- Ensure no wires are stretched tight or bunched up together too closely which could lead to wear over time or poor performance.

This methodical approach prepares diesel truck owners for successful engine wiring system installations, focusing on accuracy and safety throughout this critical task.

Connecting Sensors and Actuators

Connecting sensors and actuators is a key step in engine wiring installation. This process ensures that your diesel truck’s engine runs smoothly.

- Identify all sensor locations using the engine wiring diagram.

- Gather necessary tools, including wire strippers, connectors, and a multimeter.

- Disconnect the battery to avoid any electrical accidents.

- Start with the temperature sensor; find its position on the engine block.

- Strip the wires’ ends that will connect to the temperature sensor.

- Use quality connectors to attach wires to the sensor, ensuring a secure fit.

- Move to the oil pressure sensor, usually near the oil filter.

- Repeat the stripping and connecting process for this sensor.

- For actuators like fuel injectors, locate them on top of the engine.

- Carefully remove old wiring from each injector if upgrading or replacing.

- Connect new wires to each fuel injector using waterproof connectors.

- Ensure all connections are tight and secure with no loose wires.

- Check the throttle position sensor, typically found on the butterfly spindle of the throttle body.

- Attach wires to this sensor, making sure they are correctly positioned for accurate readings.

- Secure all new wiring with cable ties, keeping it away from hot or moving parts of the engine.

- Reconnect the battery and start the engine to test connections.

This careful approach ensures all sensors and actuators communicate properly with your diesel truck’s computer system for optimal performance

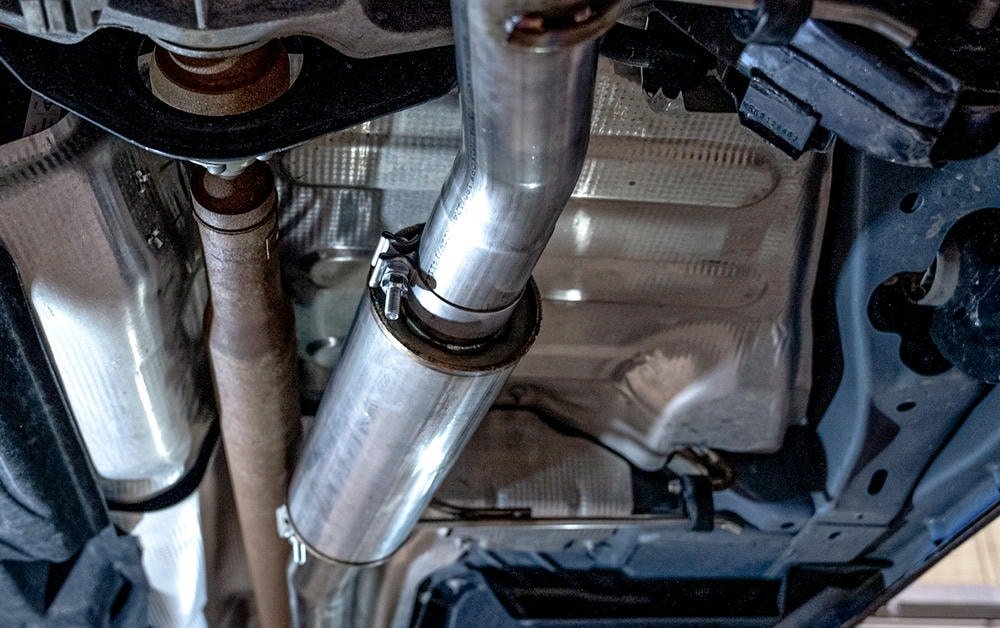

Securing the Harness and Connectors

Securing the harness and connectors is a crucial step in engine wiring installation. This process ensures that every connection in the diesel truck’s system remains stable and secure.

- Start by using zip ties to keep the wiring harness in place. Place them around the harness at intervals of about every 6 inches.

- Use electrical tape for extra security on connections that might move or vibrate. Wrap it tightly but avoid squeezing the wires.

- Install conduit or protective sleeving over areas where the harness might rub against edges or moving parts. This prevents wear and tear.

- Mount any loose connectors with brackets to prevent movement that could loosen connections over time.

- Check all ground connections making sure they are attached to clean, paint-free surfaces for a good electrical connection.

- Connect sensors and actuators firmly but without forcing them into place, which can bend pins or damage connections.

- Test each connector with a multimeter to ensure proper electrical continuity before finalizing its position.

- Label each connector and part of the harness if not already marked, to simplify future diagnostics or repairs.

- After securing everything, go through your work again, ensuring no wires are stretched tight or pinched by panels or components when reassembled.

- Carefully review areas of high heat exposure making sure wiring is routed away from exhaust components or shielded appropriately.

Following these steps helps maintain the integrity of engine wiring systems in diesel trucks, ensuring reliability and performance.

Final Testing and Troubleshooting

Final testing and troubleshooting are key steps in engine wiring installation. They help ensure everything works as it should in your diesel truck.

- Start with a visual inspection of all wiring connections. Look for loose or unconnected wires.

- Use a multimeter to check electrical continuity. This confirms that the current flows without interruption through the wiring.

- Test sensor functionality with the multimeter or a scan tool. Sensors need to respond properly for the engine to work right.

- Check for short circuits by measuring resistance across different points of the harness. Low resistance often means there’s a short.

- Turn on the ignition without starting the engine. Observe if warning lights behave as expected.

- Start the engine and monitor its behavior for unusual sounds or signs of malfunctioning.

- If you face issues, consult the vehicle’s repair manual and wiring diagrams for guidance.

- Revisit all connections, especially any you identify as problematic during testing.

From personal experience, step-by-step checking saves time in the long run by catching mistakes early on. A methodical approach helps ensure every part of your new wiring system is installed correctly and functioning well in your diesel truck, setting you up for smooth driving ahead.

Post-Installation Considerations

After installing the engine wiring system, it’s crucial to check everything works right. This means testing if all connections pass electricity well and making sure every sensor responds as expected.

If something’s not right, now is the time to fix any issues found during these tests.

Checking for Electrical Continuity

Checking for electrical continuity is crucial for a successful engine wiring installation guide. Diesel truck owners should use a multimeter to test the new system. This tool helps make sure electricity flows as it should through wires and connections.

One should touch the multimeter’s probes to two points in the circuit. If the device beeps or shows zero resistance, it means there’s good continuity; electricity can flow without blockages.

A diesel truck owner shared, “I always check each connection after installing my engine’s wiring system.” This step prevents problems before they start. It saves time and avoids headaches down the road.

Testing for electrical continuity ensures that sensors and actuators will work well when you turn on your engine.

Testing Sensor Functionality

After fitting the engine wiring systems, testing sensor functionality is a must. Diesel truck owners should use a multimeter to check if each sensor gets power and sends signals correctly.

They need to follow their vehicle’s manual for specific values expected from sensors like the oxygen sensor or the fuel pressure sensor. This step ensures that all parts of the engine communicate well with the computer.

Next, owners should start the truck and monitor how it runs. Problems like rough idling or trouble starting suggest a sensor may not work right. This test helps find issues early, making repairs easier and keeping the truck in good shape.

Addressing Any Installation Issues

If a diesel truck owner runs into issues while fitting the engine wiring systems, it helps to start by checking all connections. Loose or incorrect connections often cause most problems.

Use a multimeter to test for electrical continuity in each wire and connector. This tool will quickly show where any breaks or shorts are, making it easier to fix them.

It’s also smart to go over the installation steps again. Sometimes, a step might have been missed or done incorrectly. Looking at the manufacturer’s manual can point out what went wrong during the step-by-step wiring installation process.

If these methods don’t solve the issue, seeking advice from online forums or a professional mechanic who knows about diesel trucks can offer solutions. They may spot something that was overlooked.

Conclusion

Fitting engine wiring systems is key for diesel truck owners. For this task, John Carter shares his insights. He brings 20 years of experience in automotive engineering, a master’s degree in Mechanical Engineering, and has led many projects on vehicle electrical systems.

John says the installation process we discussed helps trucks run better. It uses science to improve how engines work. This method makes sure all parts talk to each other right.

He talks about safety too. John points out that following rules and being clear about what you’re doing is crucial. He reminds us that using certified materials matters a lot.

For everyday use, John suggests checking the system often. He says small checks can prevent big problems later.

When looking at pros and cons, he notes that while installing new wiring improves performance, it can be tricky without the right tools or knowledge. Compared to other options, this method stands out for those who do it carefully.

John’s final say? Engine wiring systems are worth fitting if done correctly with attention to safety and detail.

FAQs

What is the process of installing an engine wiring system?

Installing an engine wiring system involves a methodical structure with precise instructions and detailed explanations. It requires technical knowledge, quality materials, and attention to detail for optimal results.

Is it necessary to have technical knowledge to fit engine wiring systems?

Yes, understanding technical terminology related to engine wiring systems is crucial in ensuring proper installation. However, these terms can be explained in clear and direct language for better comprehension.

Can I rely on personal experiences while installing an engine wiring system?

While personal or widely recognized experiences can provide empirical guidance, following a structured guide that offers precision and detail enhances your ability to replicate the procedures effectively.

Why is quality emphasized when fitting an engine wiring system?

Quality emphasis ensures thoroughness in execution which leads to optimal results during the installation of the engine wiring systems. Using proper materials contributes significantly towards this goal.